Method for realizing SiC epitaxial curve-shaped doping distribution

A technology of doping distribution and epitaxial curves, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve problems such as large technical difficulties, achieve high promotional value, and improve the effect of design scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This embodiment provides a method for realizing SiC epitaxial curved doping distribution, including the following steps:

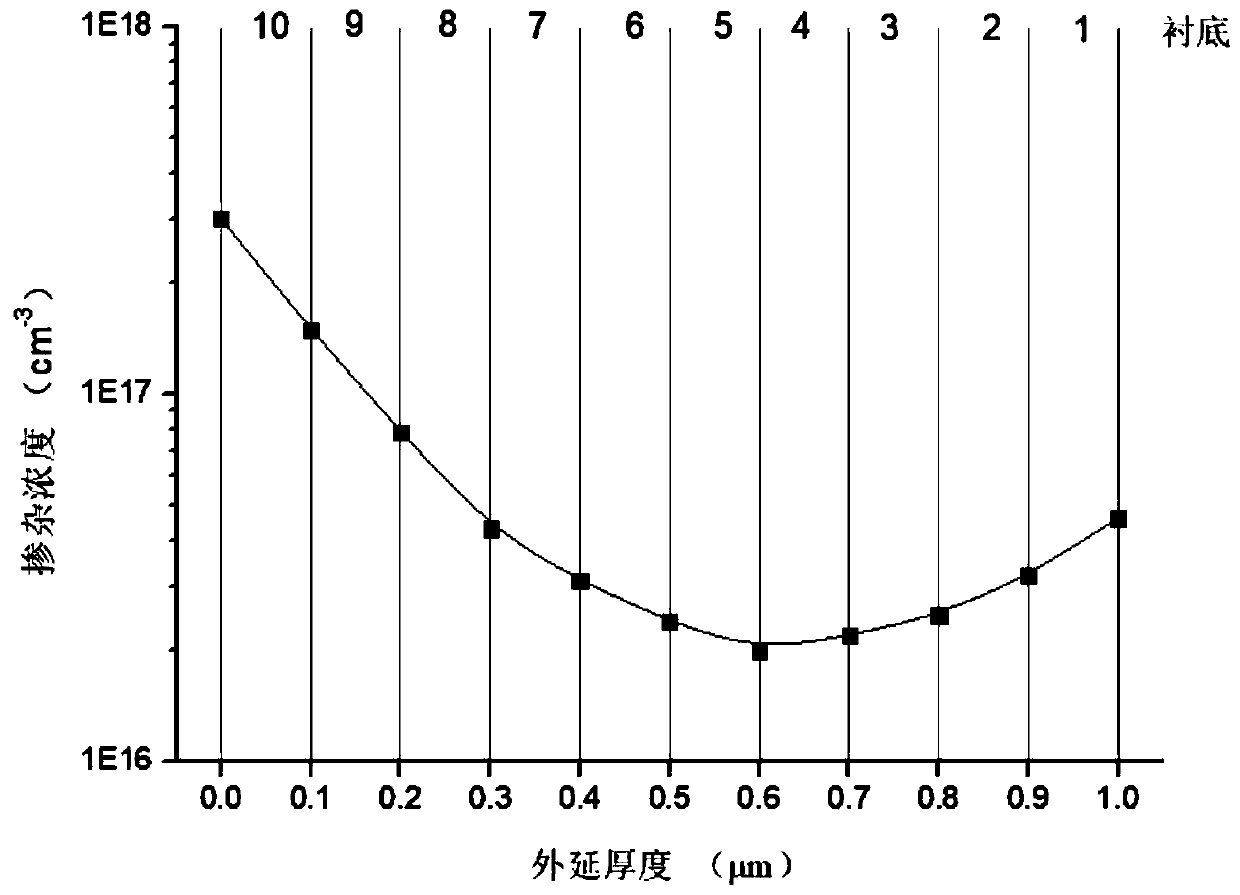

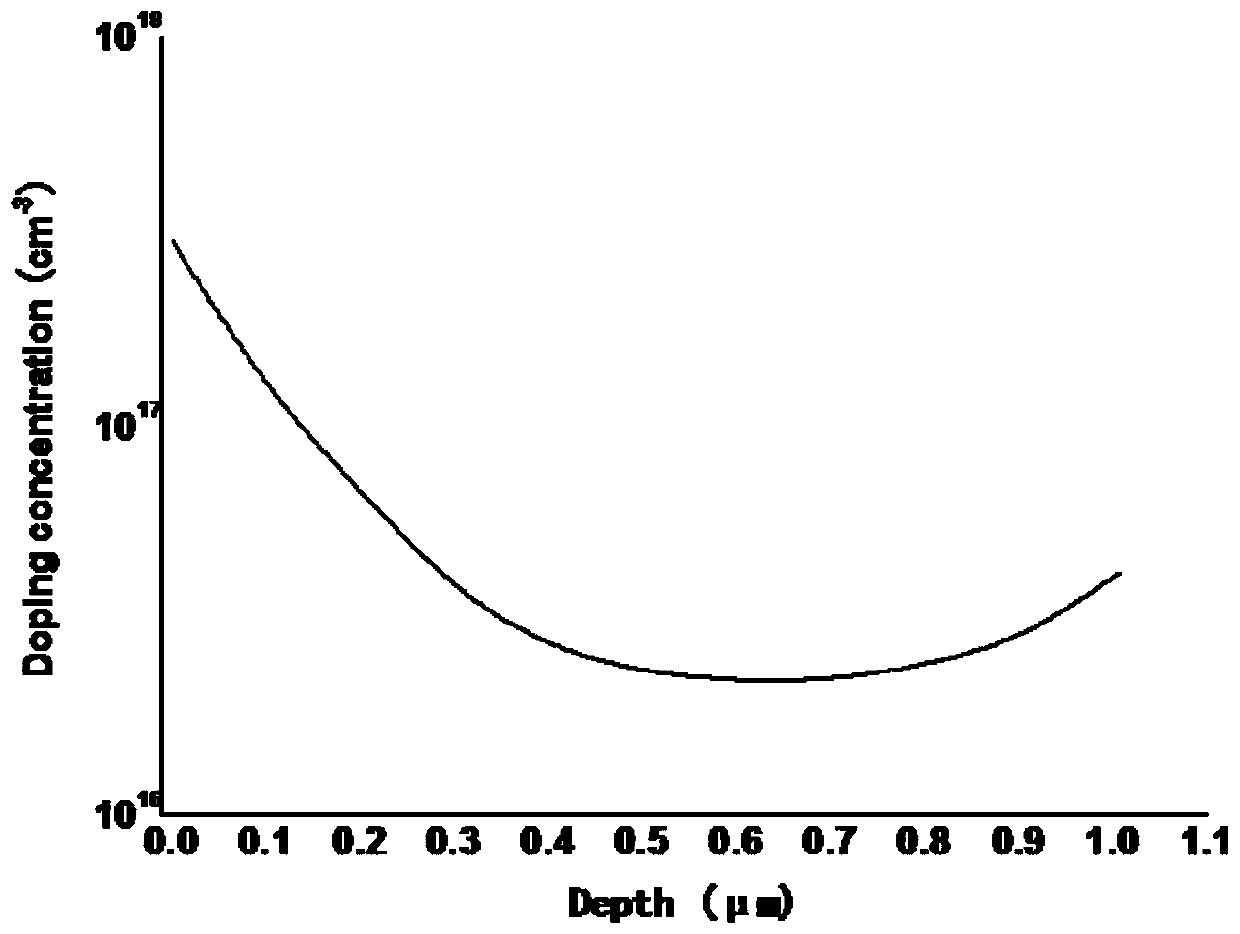

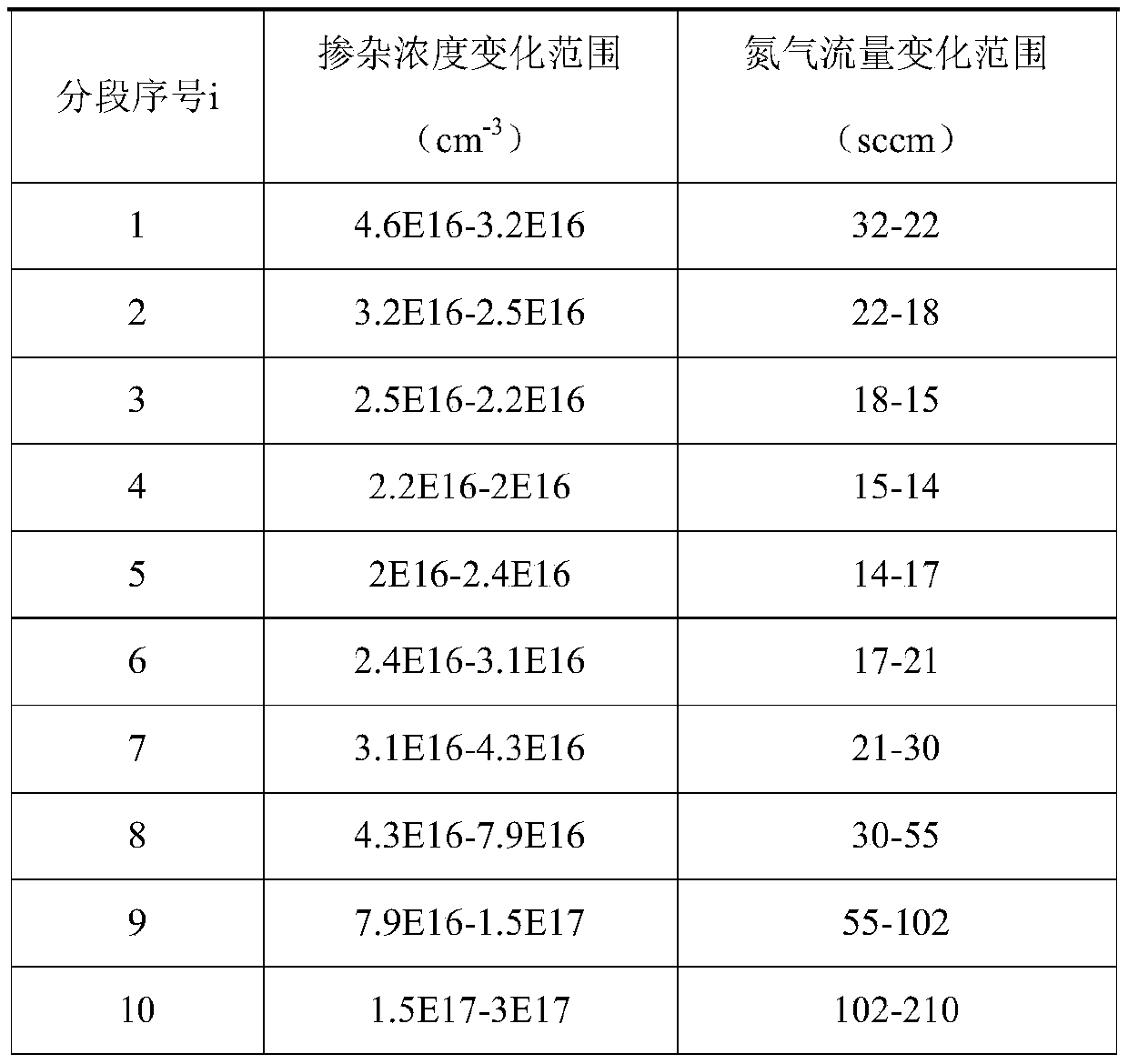

[0048] step one, yes figure 1 The doping distribution curve given in is fitted piecewise linearly, the cumulative length of the doped area of the curve is 1 μm, and the maximum doping concentration is 3E17 cm -3 , the lowest doping concentration is 2E16 cm -3 , which are respectively located on the surface of the epitaxial layer and at the position with a thickness of 0.7 μm, which are divided into 10 segments, each with a length of 0.1 μm. Select the epitaxy speed as 12μm / h, the corresponding Si / H 2 The ratio is 0.0625%. The selected C / Si ratio at the intake end is 0.85, and under this C / Si ratio condition, 3E17 cm -3 and 2E16 cm -3 The flow rates of n-type doping source nitrogen required for the epitaxial doping are 210 sccm and 14 sccm respectively. The doping concentration and the nitrogen flow are in a linear relationship, and the chang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com