Novel multi-layer belt winding type low-noise permalloy magnetic shielding barrel structure

A permalloy and magnetic shielding technology, applied in the fields of magnetic/electric field shielding, shielding materials, metal containers, etc., can solve the problems of large Johnson current noise, large structural magnetic field noise, and low resistivity, so as to save materials and magnetic field noise Great, reduce the effect of eddy current loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below with the accompanying drawings ( Figure 1-Figure 2 ) to illustrate the present invention.

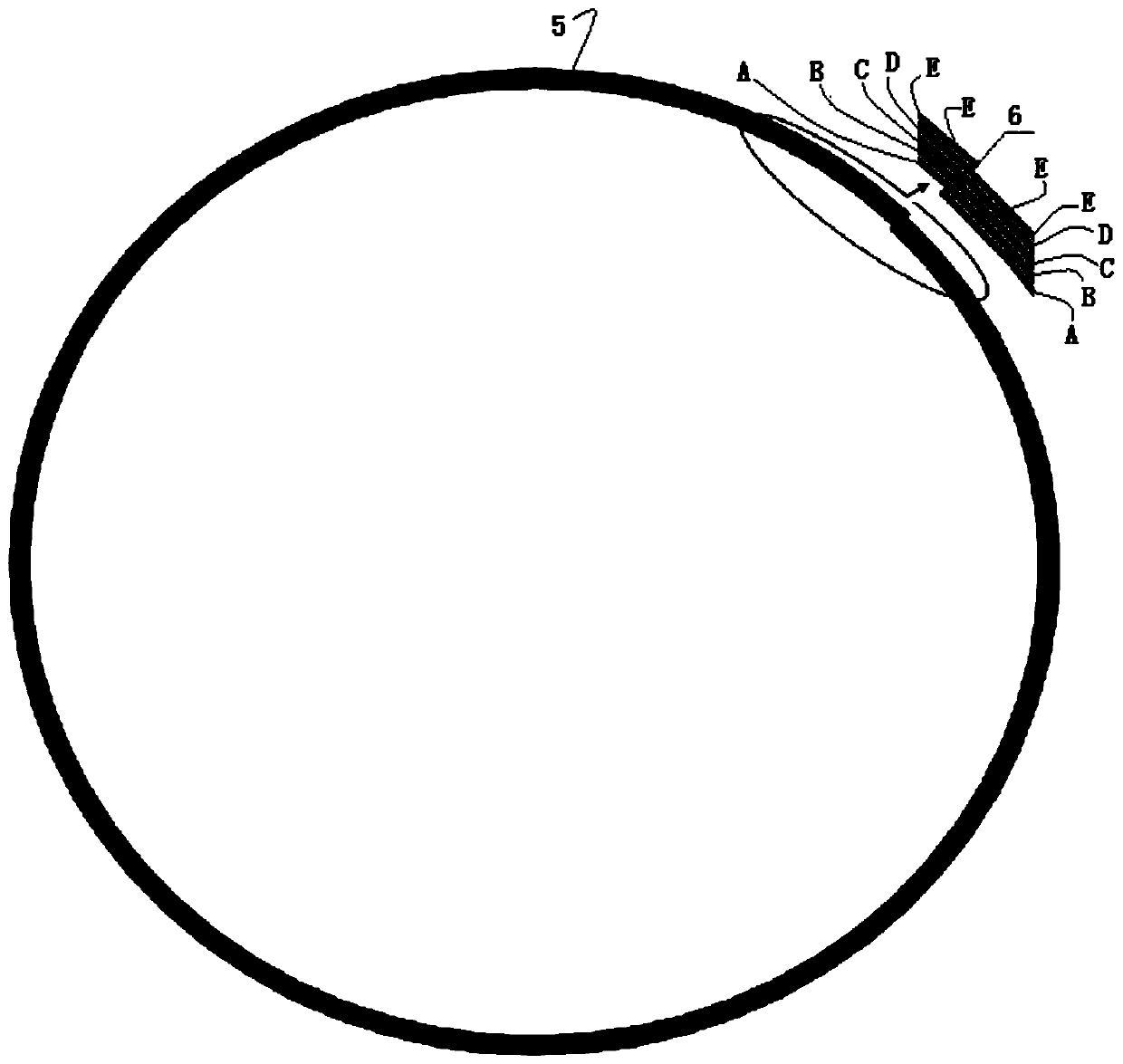

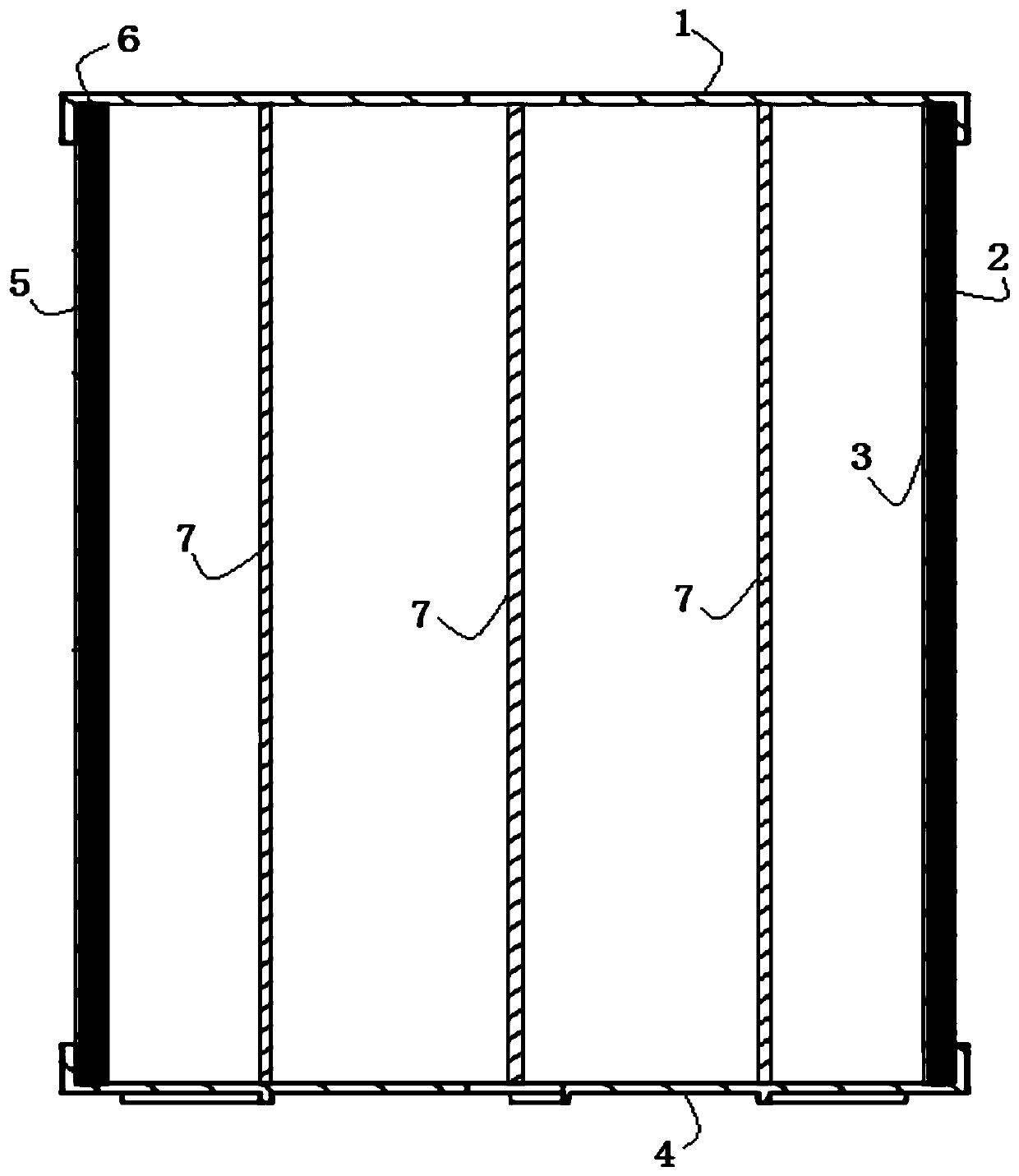

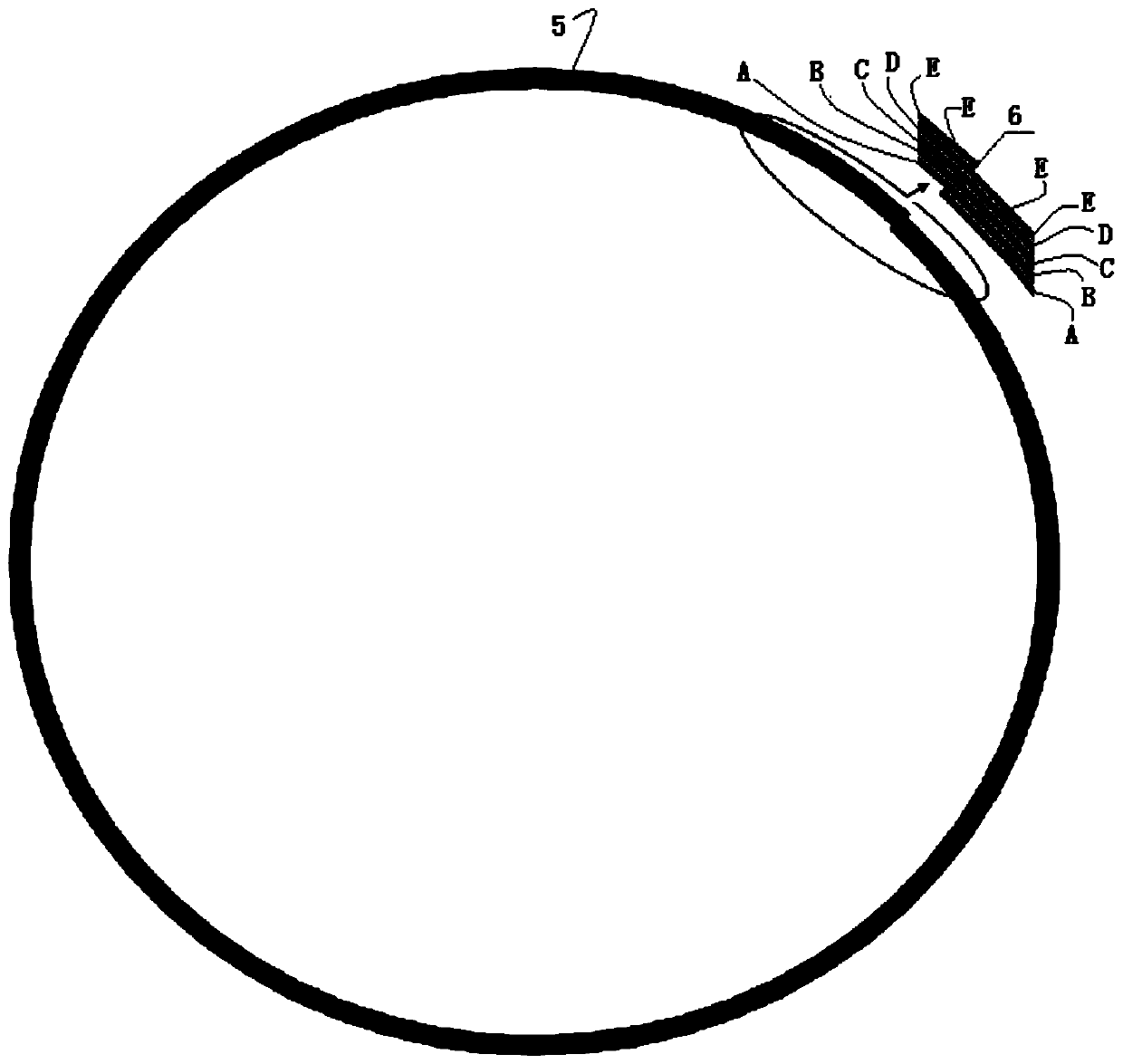

[0021] figure 1 It is a schematic diagram of the structure of the main body of the belt-wound magnetic shielding barrel implementing the present invention. figure 2 is included figure 1 Schematic diagram of a new type of multi-layer tape-wound low-noise permalloy magnetic shielding barrel with the main structure of the middle tape-wound magnetic shielding barrel. refer to Figure 1 to Figure 2 As shown, a main body structure of a tape-wound magnetic shielding barrel includes an annular barrel wall, the annular barrel wall has at least two layers of permalloy strip winding layers 5, and the surface of the permalloy strip has an insulating layer 6. The insulating layer 6 makes the radial conductive thickness of the annular barrel wall discontinuous to prevent eddy current transmission, thereby reducing eddy current loss and its Johnson current noise, while the radial m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com