Environment-friendly printing waste gas treatment system

A technology for environmental protection and waste gas treatment, which is applied to the separation of dispersed particles, spray devices, chemical instruments and methods, etc. It can solve problems such as clogging of water outlets and affecting the cleaning effect of dust particles and impurities in waste gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

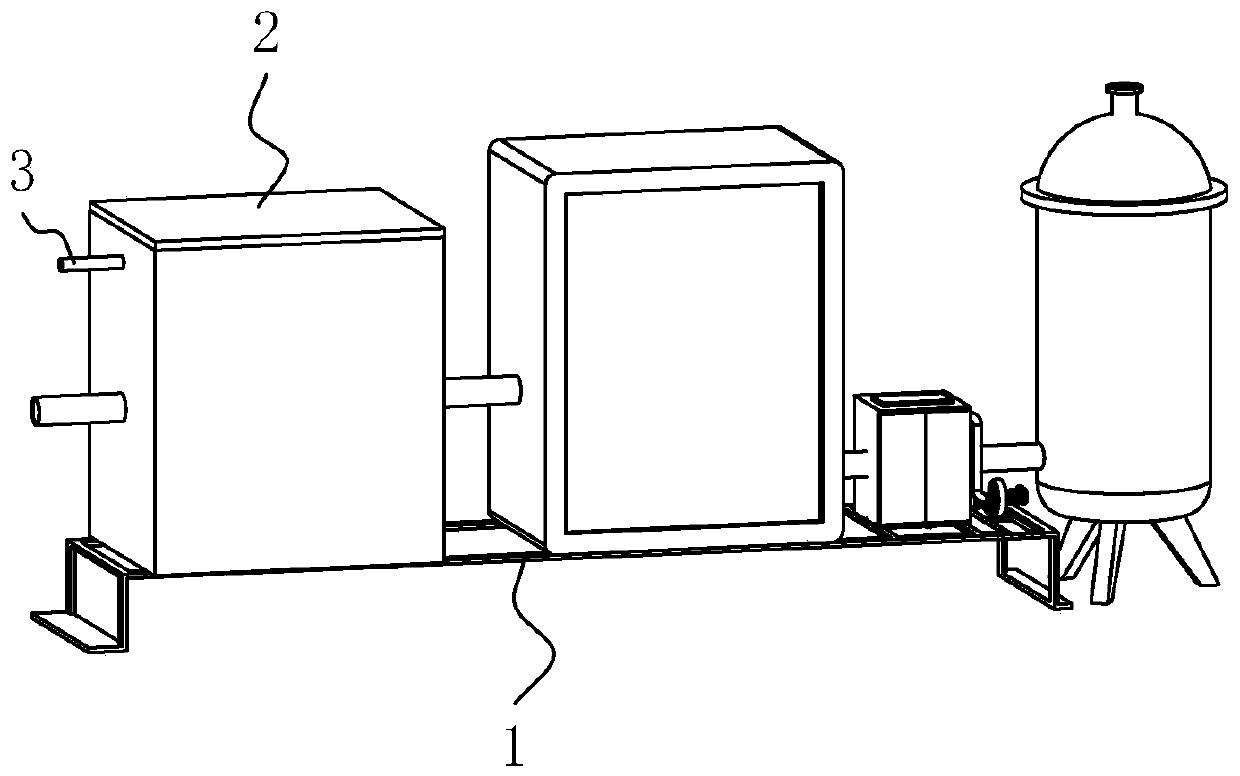

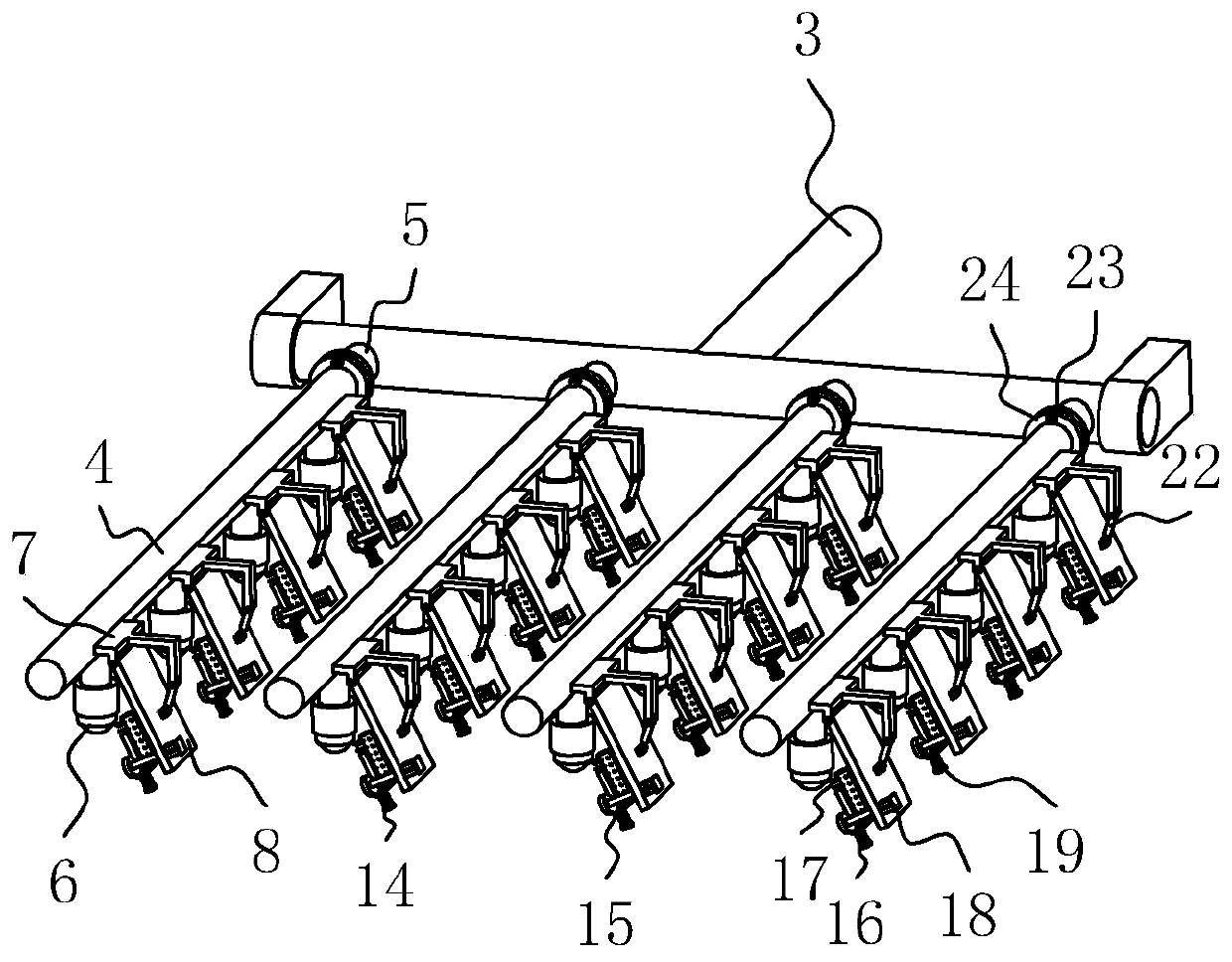

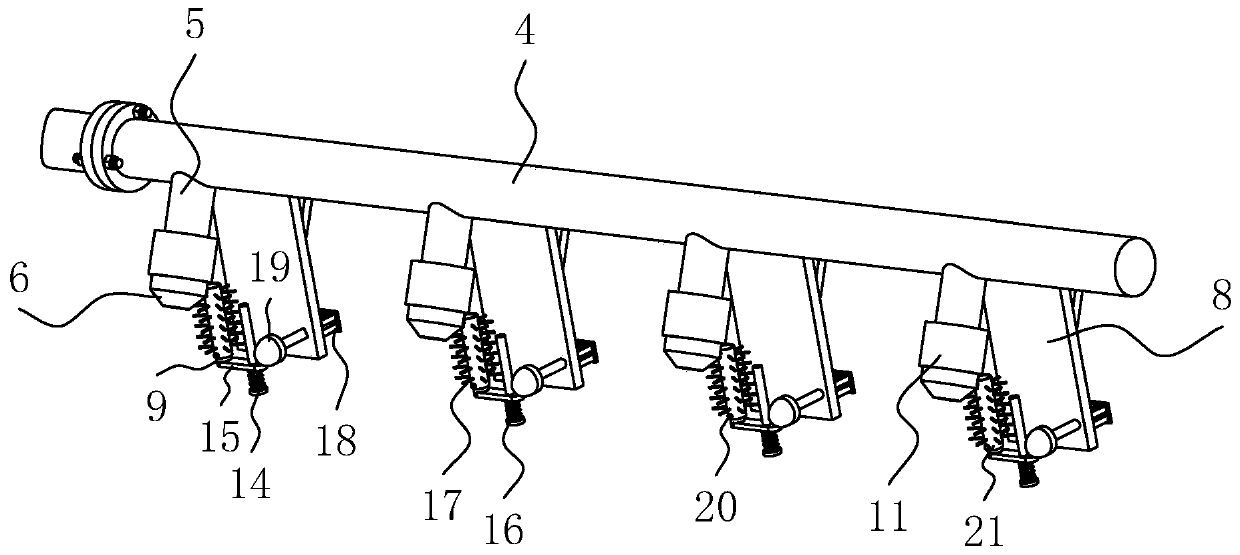

[0035] refer to figure 1 and figure 2 , is an environmental protection treatment system for printing waste gas disclosed in the present invention, comprising a machine body 1 and a water tank 2, the water tank 2 is provided with a water inlet pipe 3, and the water inlet pipe 3 is detachably provided with a plurality of spray pipes fixedly connected with the water tank 2 4. The spray pipe 4 is provided with a plurality of water outlets, and the spray pipe 4 is provided with a plurality of water outlets. The spray pipe 4 is connected with a water outlet column 5 at the position of the water outlet, and the water outlet column 5 is connected with the spray pipe 4. Fixedly connected, the water outlet column 5 is detachably provided with a nozzle 6, the nozzle 6 is a water spray device in the prior art, the water tank 2 is provided with an air inlet and an air o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap