Desulfurization synergistic device used in desulfurization column

A desulfurization tower and paddle technology, applied in the field of machinery, can solve problems such as blades and flue gas easily causing oscillation effects, unsatisfactory flue gas desulfurization effect, and unstable operation of the device, so as to widen the working load range, reduce vibration, and improve The effect of the swirl effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

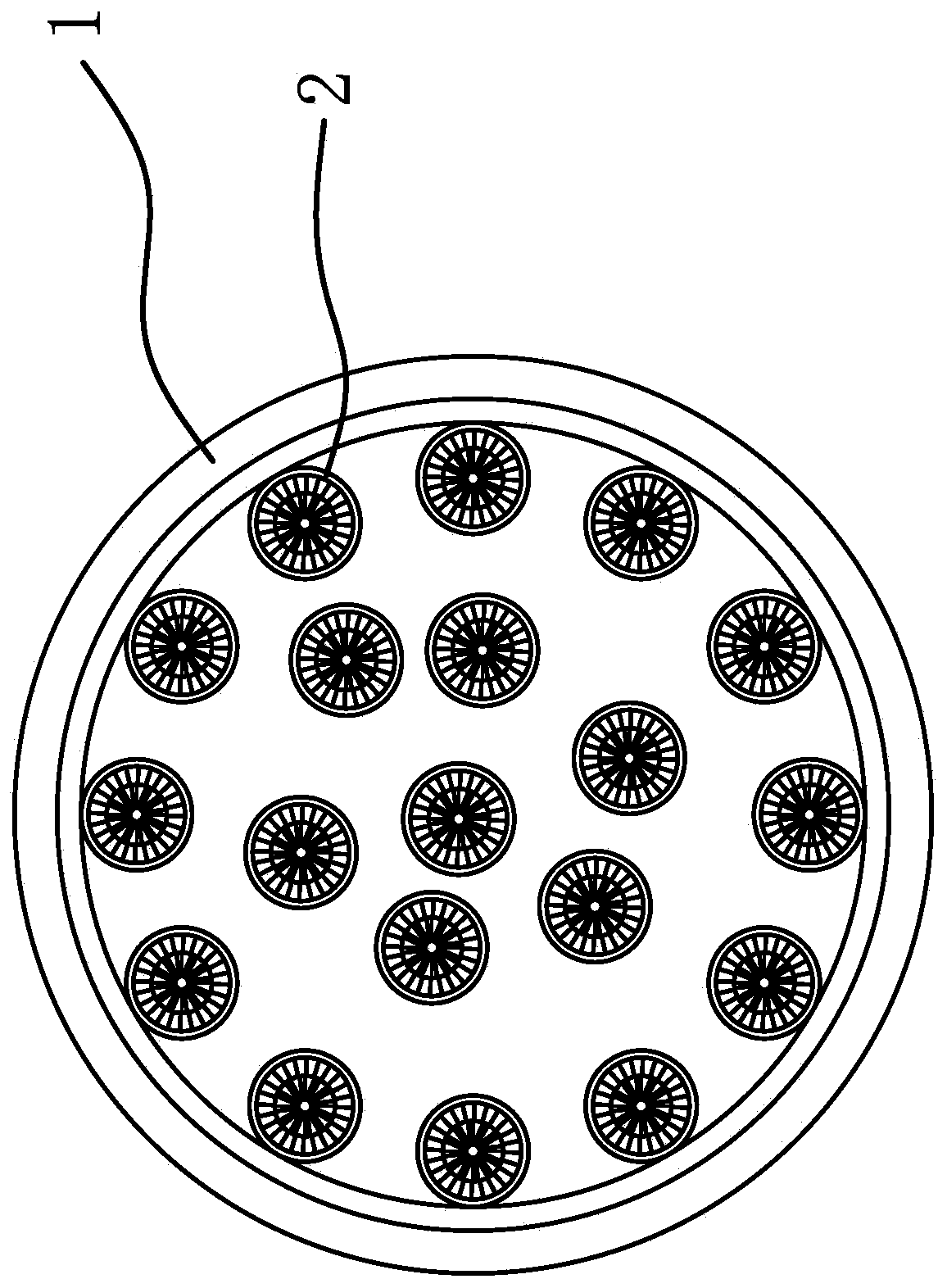

[0026] Such as figure 1 and figure 2 and image 3 and Figure 4 As shown, the desulfurization synergistic device used in the desulfurization tower includes a cylindrical shell 1, and also includes a number of cylindrical processing cylinders, each of which has a flue gas that can pass through it. It is transformed into a swirling flow structure of swirling flue gas, and several processing cylinders are all arranged in the casing.

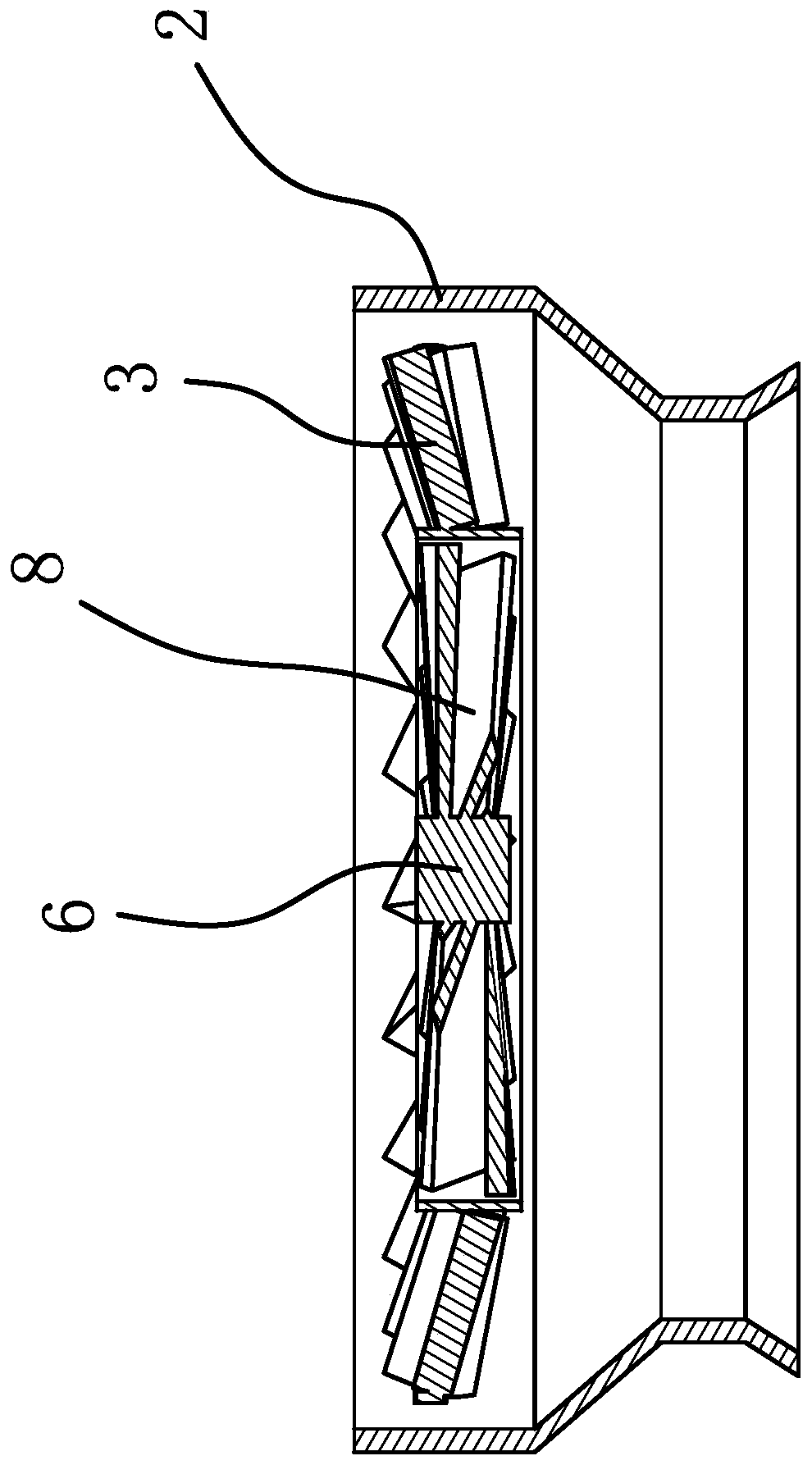

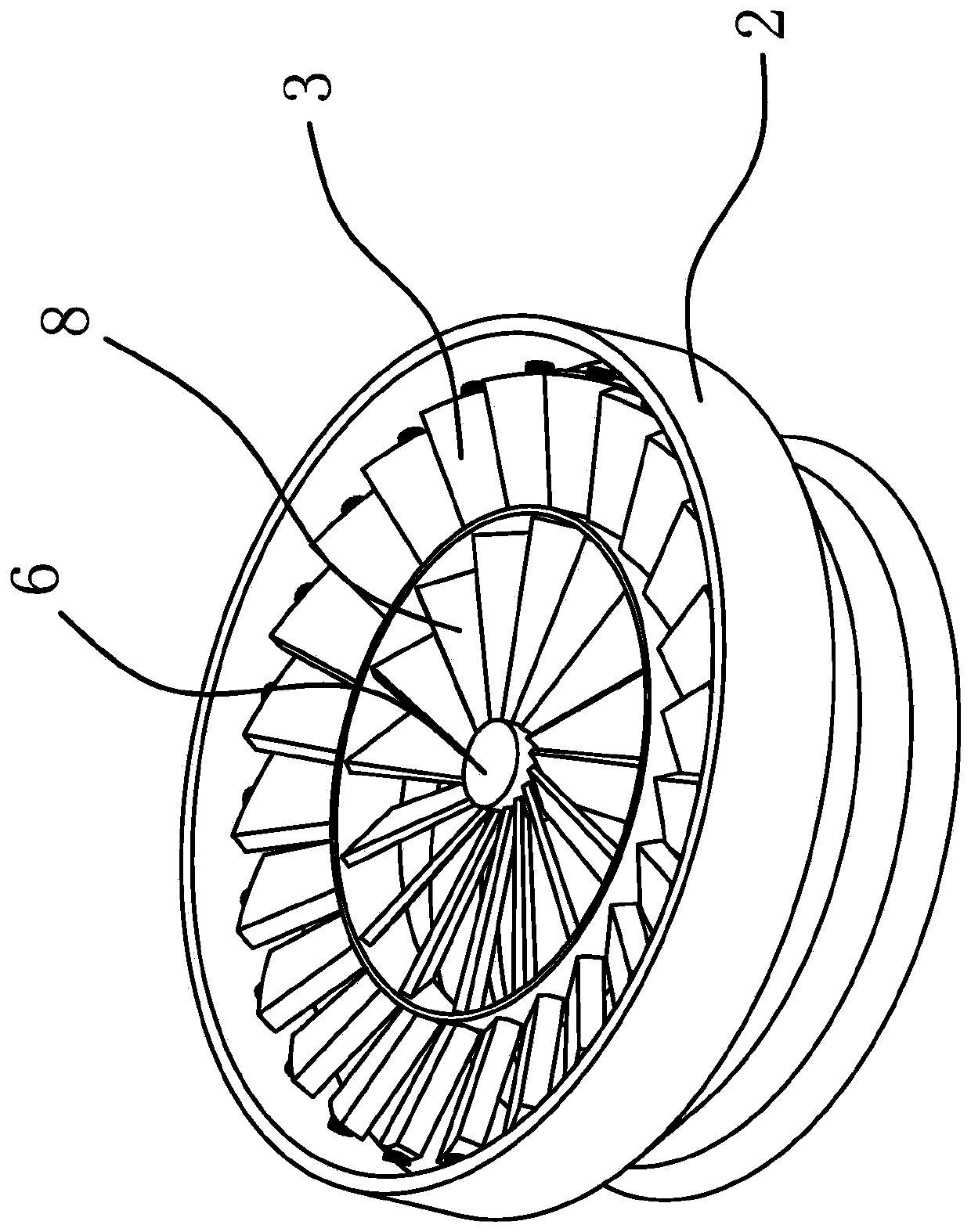

[0027] The processing cylinder includes a cylinder body 2 , a paddle assembly and a swirl assembly. The cylinder body 2 is cylindrical, the swirl assembly is located inside the cylinder body 2 , and the paddle assembly is connected to the center of the cylinder body 2 .

[0028] The swirl assembly includes a number of slices 3 arranged obliquely, and the slices 3 are evenly distributed inside the cylinder body 2 , and a channel for swirling the smoke is formed between two adjacent slices 3 .

[0029] The paddle assembly includes a driver and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com