Efficient preparation machine for ceramic glaze production

A technology for ceramic glazes and preparation machines, which is applied to mixers, screens, grills, etc., and can solve problems such as low automation, inability to meet industrial production, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

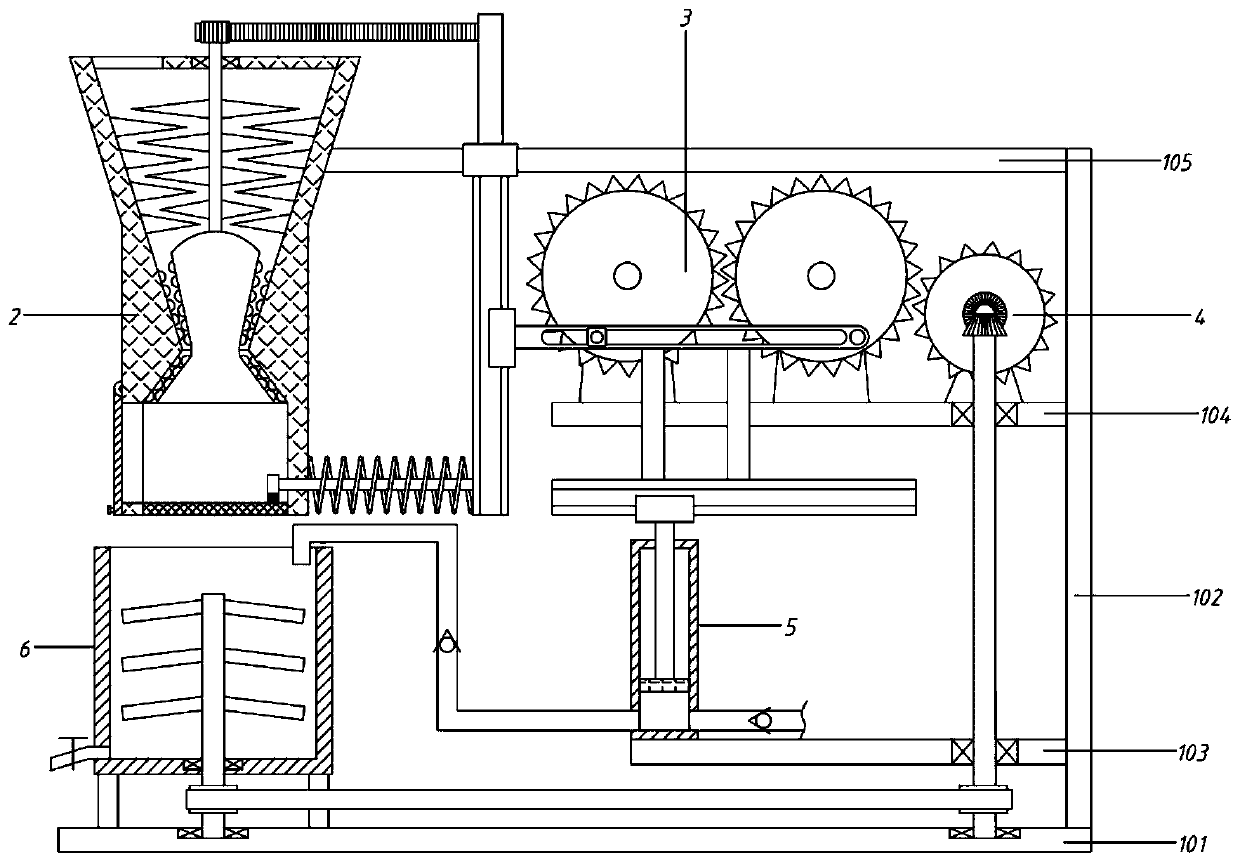

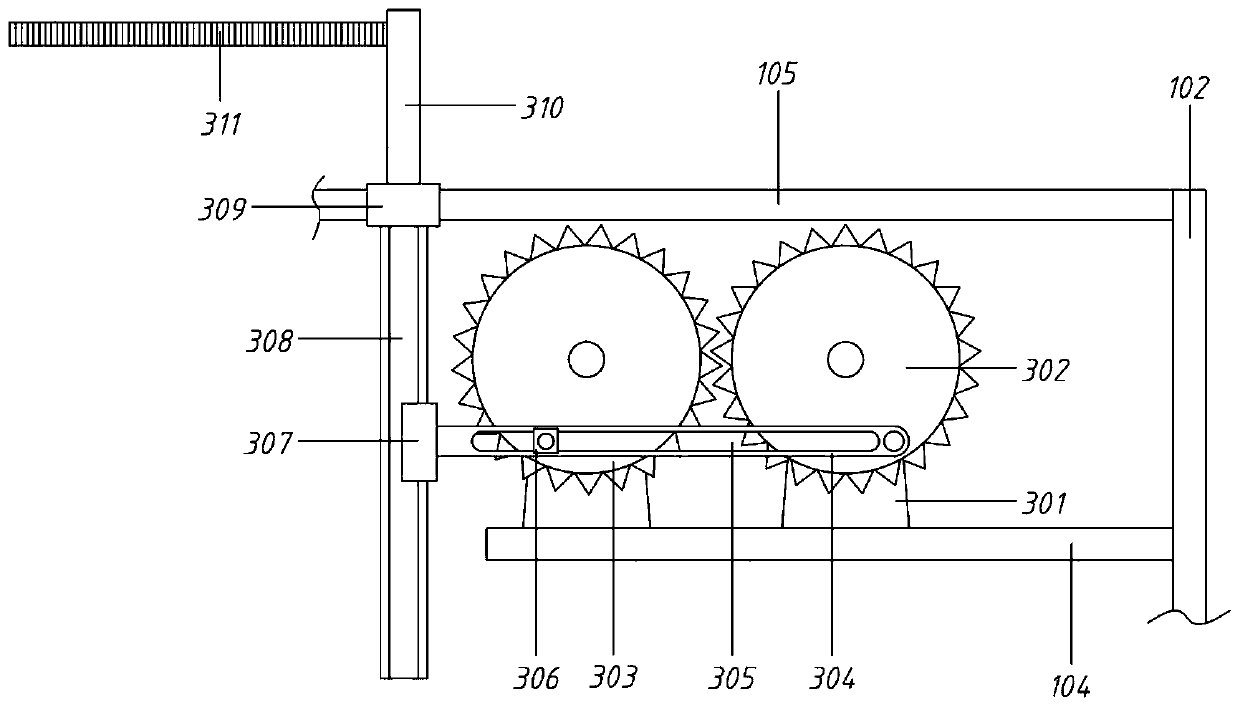

[0050] A high-efficiency preparation machine for ceramic glaze production, including a feeding tube 2;

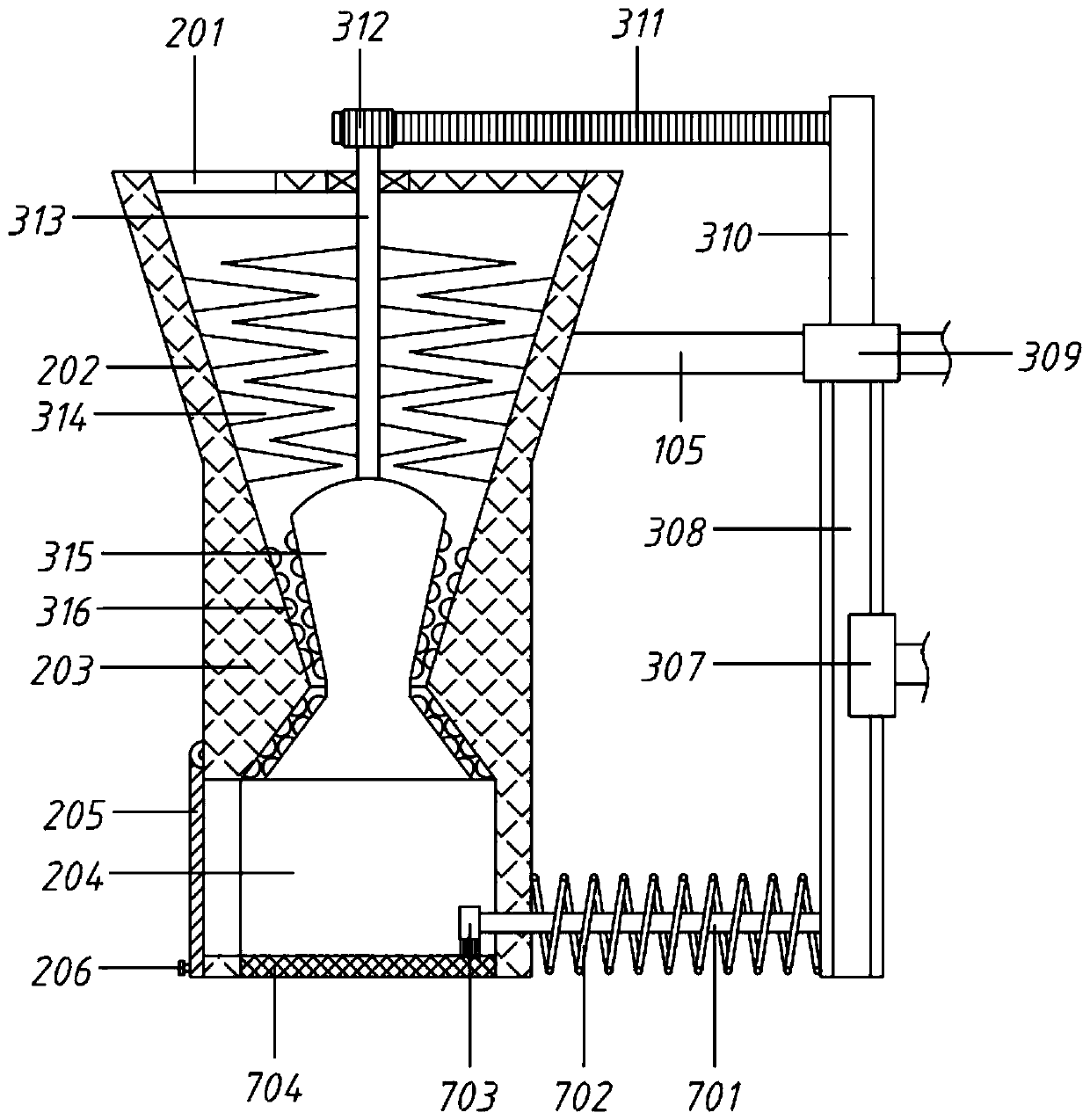

[0051] The upper part of the feeding pipe 2 is a hopper 201 with a large upper part and a smaller one; staggered pulverizer knives 314;

[0052] The bottom end of the first rotating shaft 313 extends into the middle section of the feeding pipe 2 and is connected with a grinding end 315. The inner wall of the middle section of the feeding pipe 2 corresponds to the grinding end 315 and is processed with a guide protrusion 203, and the grinding end 315 and the guide protrusion 203 forms a grinding channel; the grinding end 315 and the guide protrusion 203 are also provided with a grinding protrusion 316;

[0053] The lower section of the feeding pipe 2 is a filter chamber 204, and the bottom end of the feeding pipe 2 is equipped with a filter screen 704.

[0054] Wherein, the grinding end 315 includes upper and lower parts, the upper part is a narrowing structure with a larg...

Embodiment 2

[0061] A high-efficiency preparation machine for ceramic glaze production, including a feeding tube 2;

[0062] The upper part of the feeding pipe 2 is a hopper 201 with a large upper part and a smaller one; staggered pulverizer knives 314;

[0063] The bottom end of the first rotating shaft 313 extends into the middle section of the feeding pipe 2 and is connected with a grinding end 315. The inner wall of the middle section of the feeding pipe 2 corresponds to the grinding end 315 and is processed with a guide protrusion 203, and the grinding end 315 and the guide protrusion 203 forms a grinding channel; the grinding end 315 and the guide protrusion 203 are also provided with a grinding protrusion 316;

[0064] The lower section of the feeding pipe 2 is a filter chamber 204, and the bottom end of the feeding pipe 2 is equipped with a filter screen 704.

[0065] Wherein, the grinding end 315 includes upper and lower parts, the upper part is a narrowing structure with a larg...

Embodiment 3

[0072] A high-efficiency preparation machine for ceramic glaze production, including a feeding tube 2;

[0073] The upper part of the feeding pipe 2 is a hopper 201 with a large upper part and a smaller one; staggered pulverizer knives 314;

[0074] The bottom end of the No. 1 rotating shaft 313 extends into the middle section of the feeding pipe 2 and is connected with a grinding end 315. The inner wall of the middle section of the feeding pipe 2 corresponds to the grinding end 315 and is processed with a guide protrusion 203, and the grinding end 315 and the guide protrusion 203 forms a grinding channel; the grinding end 315 and the guide protrusion 203 are also provided with a grinding protrusion 316;

[0075] The lower section of the feeding pipe 2 is a filter chamber 204, and the bottom end of the feeding pipe 2 is equipped with a filter screen 704.

[0076] Wherein, the grinding end 315 includes upper and lower parts, the upper part is a shrinking structure with a larg...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap