Air way spiral wire cutting deice

A cutting device and helical wire technology, applied in the field of rail transit, can solve the problems of severe pantograph-catenary, not easily damaged, air leakage, accidents, etc., and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

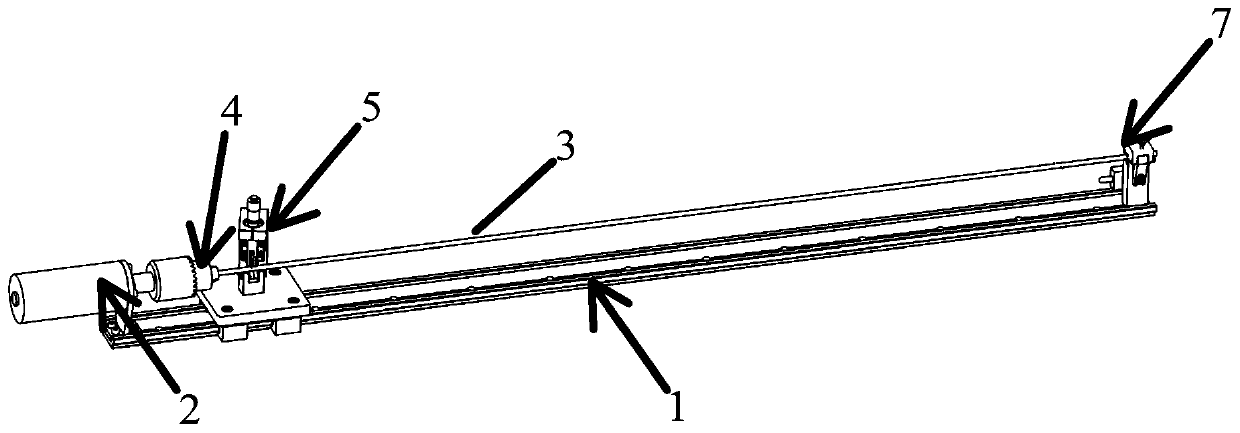

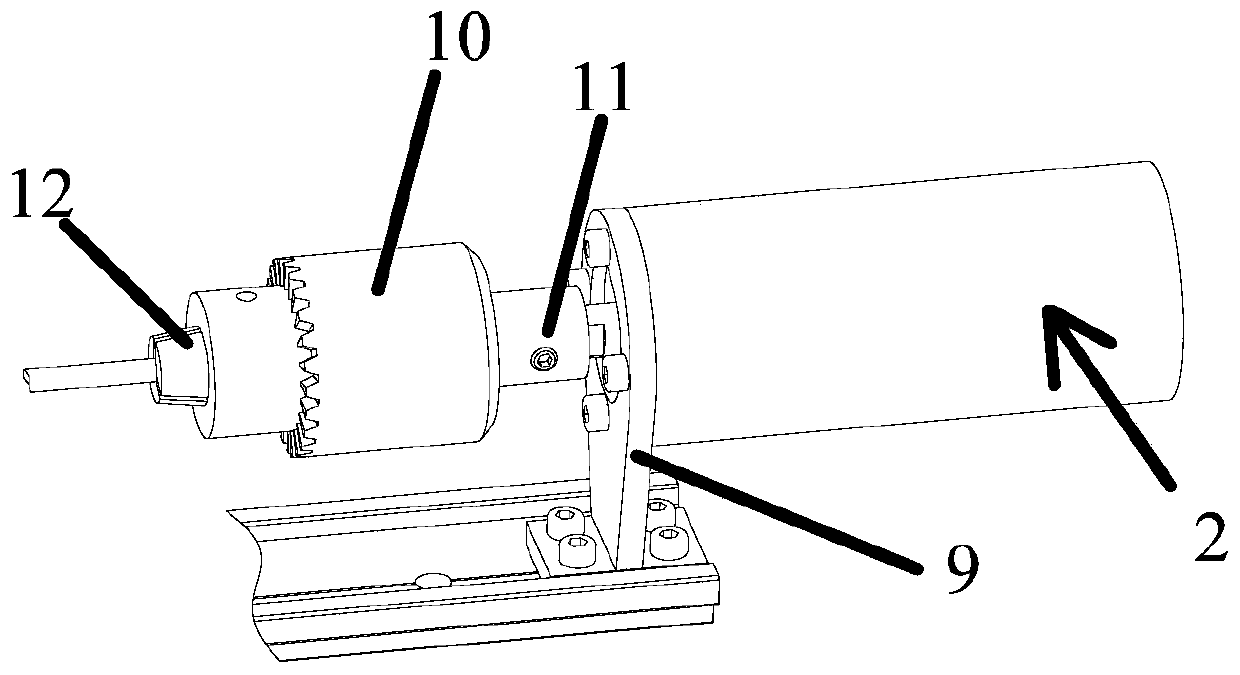

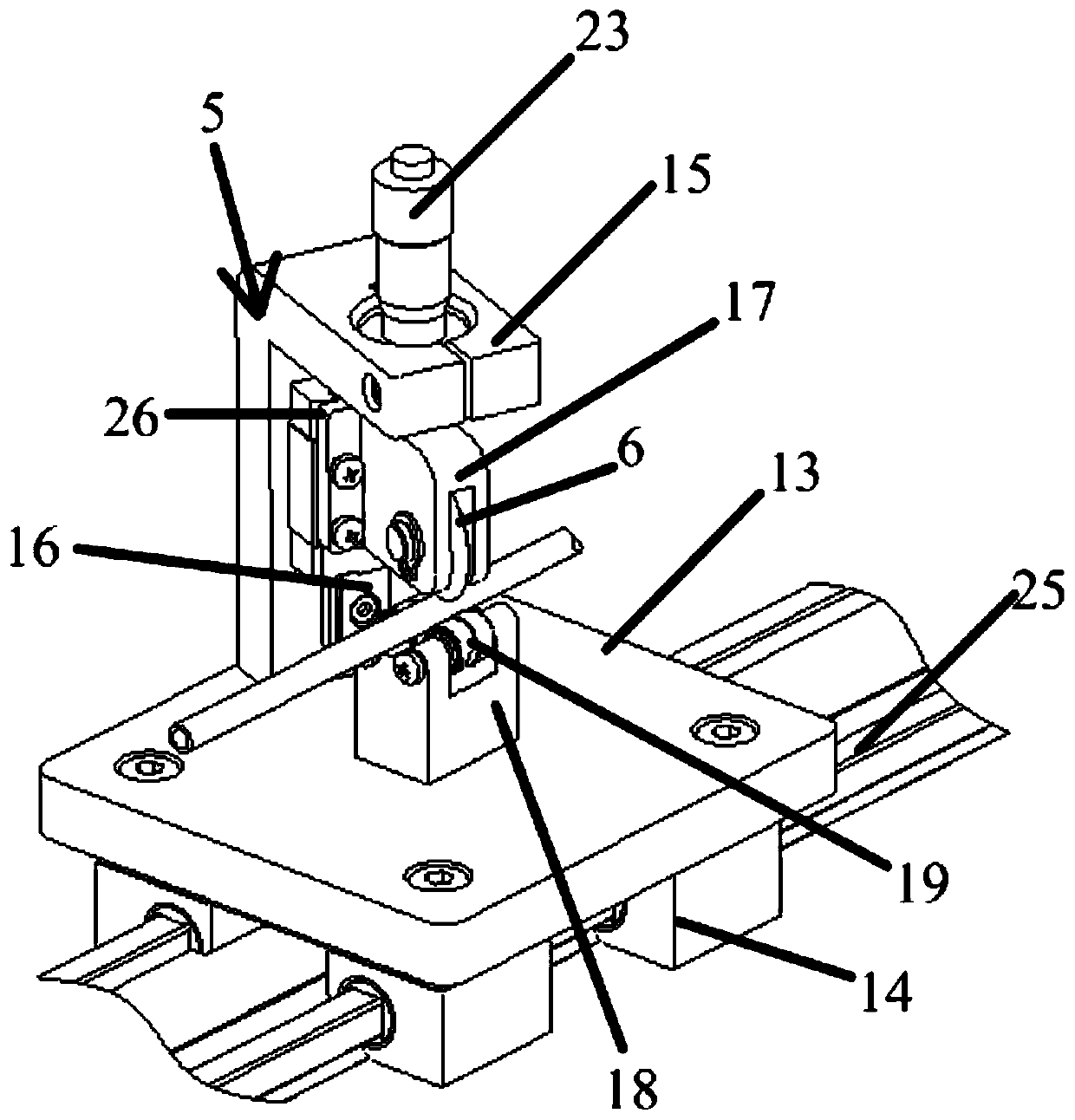

[0034] This embodiment provides a helical wire cutting device for the outer circular surface of the airway, including: a bracket body 1; a drive assembly 2, which is arranged at one end of the bracket body 1, and the drive assembly 2 is provided with a rotation mechanism for fixing the airway 3; Part 4, the rotating part 4 drives the air passage 3 to rotate by the motor on the drive assembly 2; the cutting wheel assembly 5 is slidably arranged on the bracket body 1, and the cutting wheel assembly 5 is set There is a cutter wheel 6, which cuts the radial direction of the air passage 3, and the angle between the cutter wheel 6 and the axis of the air passage 3 is set at a non-right angle; The channel is mostly a metal tube structure. However, due to the good toughness of the metal tube, when the carbon slide is deformed, it is not easy to damage and leak air in the uncut area or part of the cut area of the air channel, so that when the carbon slide is deformed, the bow will be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com