Conical barrel device for crushing, cutting and trimming concrete

A technology of concrete and cone barrels, which is applied in the direction of stone processing tools, work accessories, manufacturing tools, etc., can solve the problems of imperfect performance, shallow pile breakage, low efficiency, etc. damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

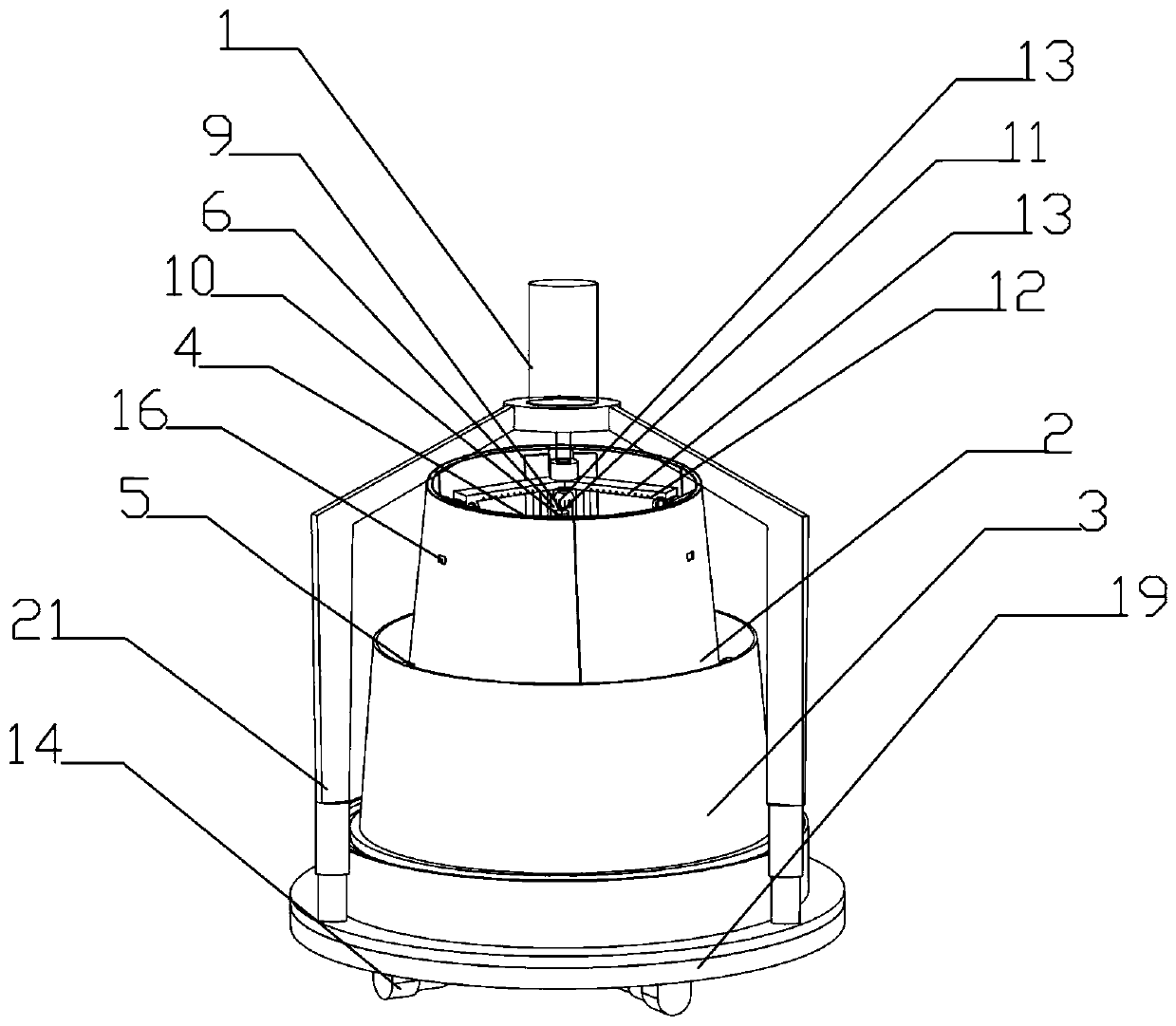

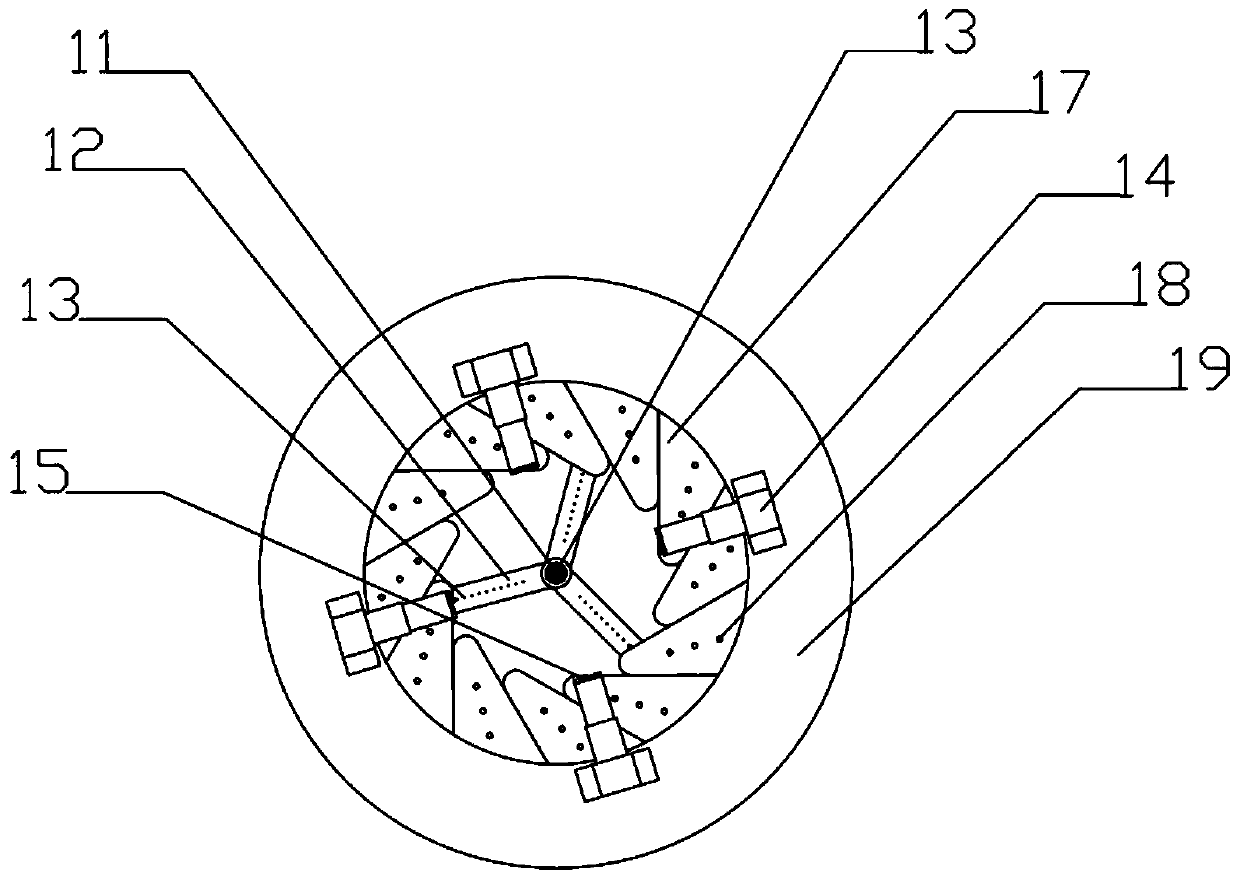

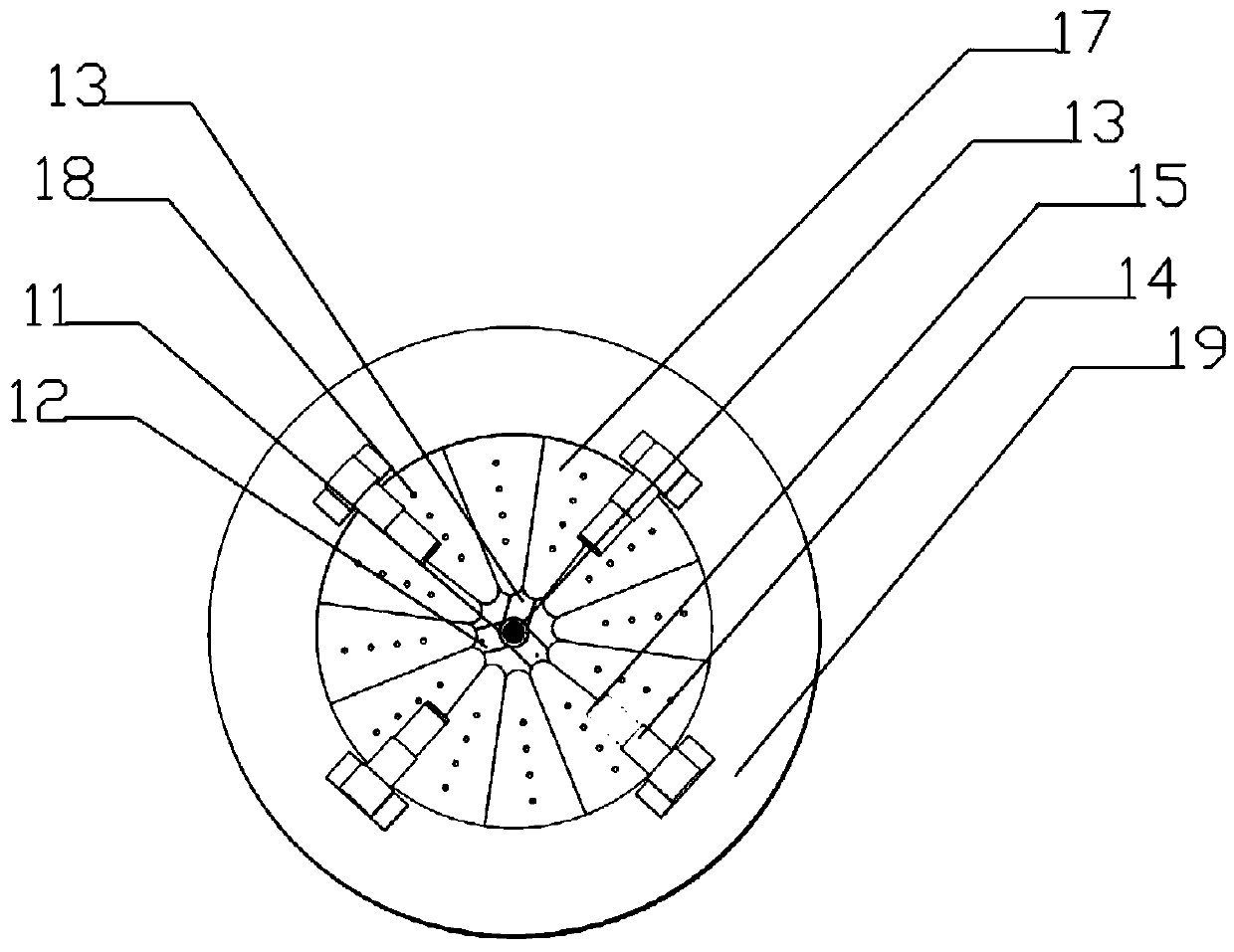

[0037]Referring to the accompanying drawings, a cone device for crushing and cutting and trimming concrete includes a motor 1, a double-layer cone device, a cleaning device, and a collection device. The double-layer cone device includes an upper cone 2 and a lower cone 3, The top of the upper cone barrel 2 is fixedly connected with the motor 1, and it is characterized in that the motor 1 is fixed in position by a telescopic bracket 21, and the lower end of the telescopic bracket 21 is fixed on the pallet 19; the upper cone barrel 2 is made of three identical curved steel plates 4 spliced together, the lower cone barrel 3 is made of a trapezoidal barrel and a vertical barrel, the outer wall of the bottom of the upper cone barrel 2 is provided with a slider 25, and the inner wall of the lower cone barrel 3 is provided with a vertical installation and Three sets of electric guide rails 5 with sliders 25 paired with each other can slide relative to each other through the slide bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com