Imidazole polypyrophosphate flame retardant and preparation method thereof

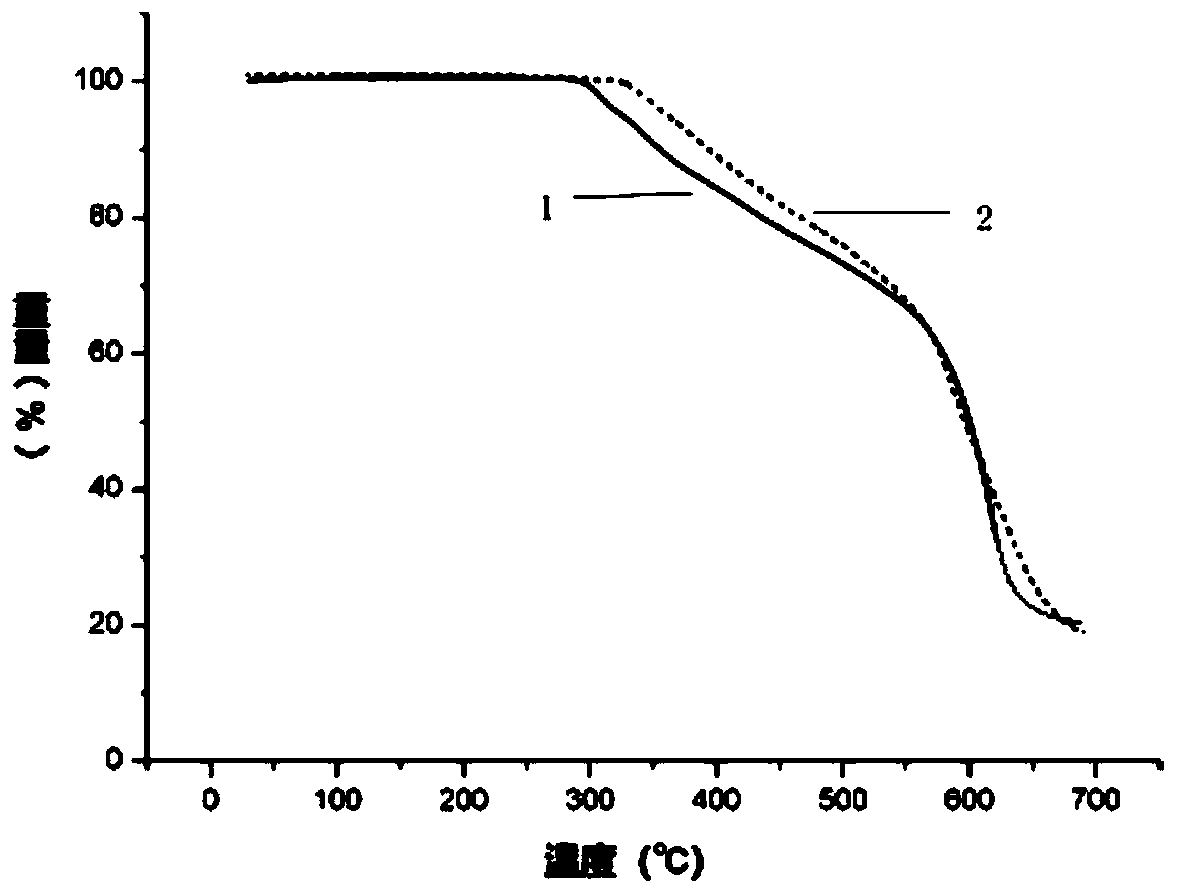

The technology of imidazole phosphate and imidazolium phosphate is applied in the field of phosphorus nitrogen flame retardants, which can solve problems such as easy combustion, and achieve the effects of improving flame retardant efficiency, simple and practical preparation method, and high thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Add 10 kg of 85% phosphoric acid solution into the reactor, the rotating speed is increased to 60rmp, and the temperature is increased to 100°C. Add a saturated aqueous solution of imidazole in a spray mode, wherein the imidazole content is 12.25 kg. After reacting for 1 hour, the water was distilled off under reduced pressure to obtain 20.5 kg of imidazolium phosphate as a white solid. Add imidazolium phosphate into the vacuum kneader, increase the speed to 50 rpm, replace with nitrogen for more than three times, raise the temperature to 280°C, and react for 3 hours to obtain imidazole pyropolymerized phosphate.

Embodiment 2

[0042] Add 10 kg of 85% phosphoric acid solution into the reactor, the rotating speed is increased to 60rmp, and the temperature is increased to 100°C. Add a saturated aqueous solution of imidazole in a spraying manner, wherein the content of imidazole is 12.25 kg, and adjust the pH of the solution to 5-6 to stop adding the saturated aqueous solution of imidazole. After reacting for 1 hour, the water was distilled off under reduced pressure to obtain 22.7 kg of imidazolium phosphate as a white solid. Add imidazolium phosphate into the vacuum kneader, increase the speed to 50 rpm, replace with nitrogen for more than three times, raise the temperature to 280°C, and react for 3 hours to obtain imidazole pyropolymerized phosphate.

Embodiment 3

[0044] Add 10 kg of 85% phosphoric acid solution into the reactor, the rotating speed is increased to 60rmp, and the temperature is increased to 100°C. Add a saturated aqueous solution of imidazole in a spraying manner, wherein the content of imidazole is 12.25 kg, and adjust the pH of the solution to 5-6 to stop adding the saturated aqueous solution of imidazole. After reacting for 1 hour, the water was distilled off under reduced pressure to obtain 23.1 kg of imidazolium phosphate as a white solid. Add imidazolium phosphate into the vacuum kneader, increase the rotation speed to 50 rpm, replace with nitrogen for more than three times, raise the temperature to 300°C, and react for 1.5 hours to obtain imidazole pyropolymerized phosphate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com