A kind of cigarette joint glue and lap glue and preparation method thereof

A cigarette lapping and mouthpiece glue technology, which is applied in the field of cigarette glue, can solve problems such as unsatisfactory effects, and achieve the effect of solving the contradiction between low-viscosity smearing and high adhesion, low viscosity, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

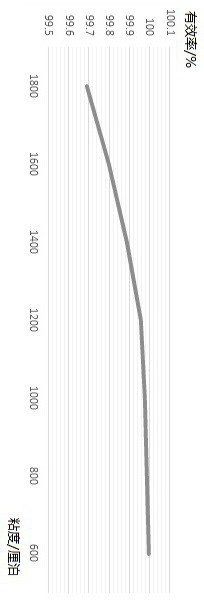

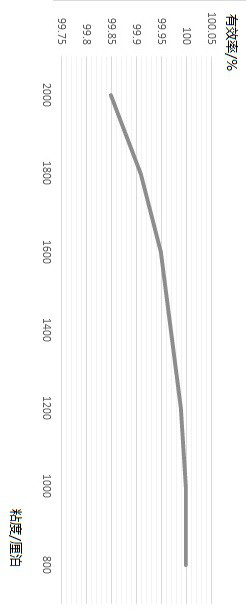

Image

Examples

preparation example Construction

[0046] The preparation method of cigarette mouthpiece glue and lap glue of the present invention comprises the following steps:

[0047] (1) First prepare vinyl acetate-ethylene copolymer and water at a mass ratio of 1:5 to form a vinyl acetate-ethylene copolymer emulsion, and heat it to 45°C.

[0048] (2) Melt lotus root starch into 60°C water at a mass ratio of 1:5, and stir thoroughly to form a suspension.

[0049] (3) During the stirring process, add vinyl acetate-ethylene copolymer emulsion to lotus root starch suspension in proportion; add ethanol, SE-11 sucrose fatty acid ester in sequence, and then add 60°C hot water to dilute to the specified ratio, and cool Then it can be packaged to become a finished product.

Embodiment 1

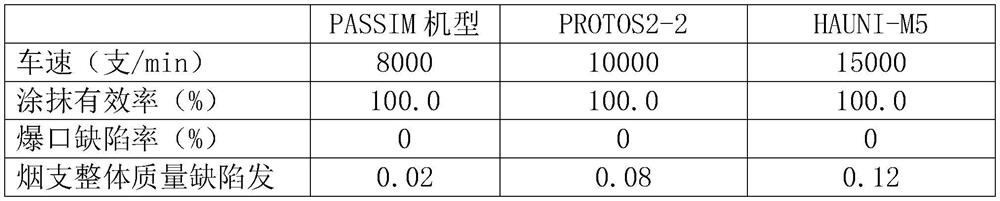

[0051] According to the test and analysis of a certain cigarette machine model (vehicle speed 12000 cigarettes / min), we designed a fast-curing mouth glue and lap glue respectively for this model of cigarette making machine. The design viscosity of the mouth glue is 850 centipoise, and The design viscosity is 550 centipoise, and the original formula design ratio is as follows:

[0052] Mouth glue (No. CVAE04) ingredient list

[0053] ingredients Proportion Vinyl acetate-ethylene copolymer emulsion (vinyl acetate-ethylene copolymer ratio 45%) 15% lotus root starch 4% water 78% ethanol 2% SE-11 Sucrose Fatty Acid Ester 1%

[0054] Viscosity 850 centipoise (temperature: 25±2°C, humidity 60±5%, standard atmospheric pressure).

[0055] Lap mouth glue (No. CVAE08) ingredient list

[0056] ingredients Proportion Vinyl acetate-ethylene copolymer emulsion (vinyl acetate-ethylene copolymer ratio 45%) 10% lotus root star...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com