Gasoline engine oil composition and preparation method thereof

A technology of gasoline engine oil and composition, which is applied in lubricating composition, petroleum industry, additives, etc., and can solve problems such as large amount of addition and suboptimal formulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

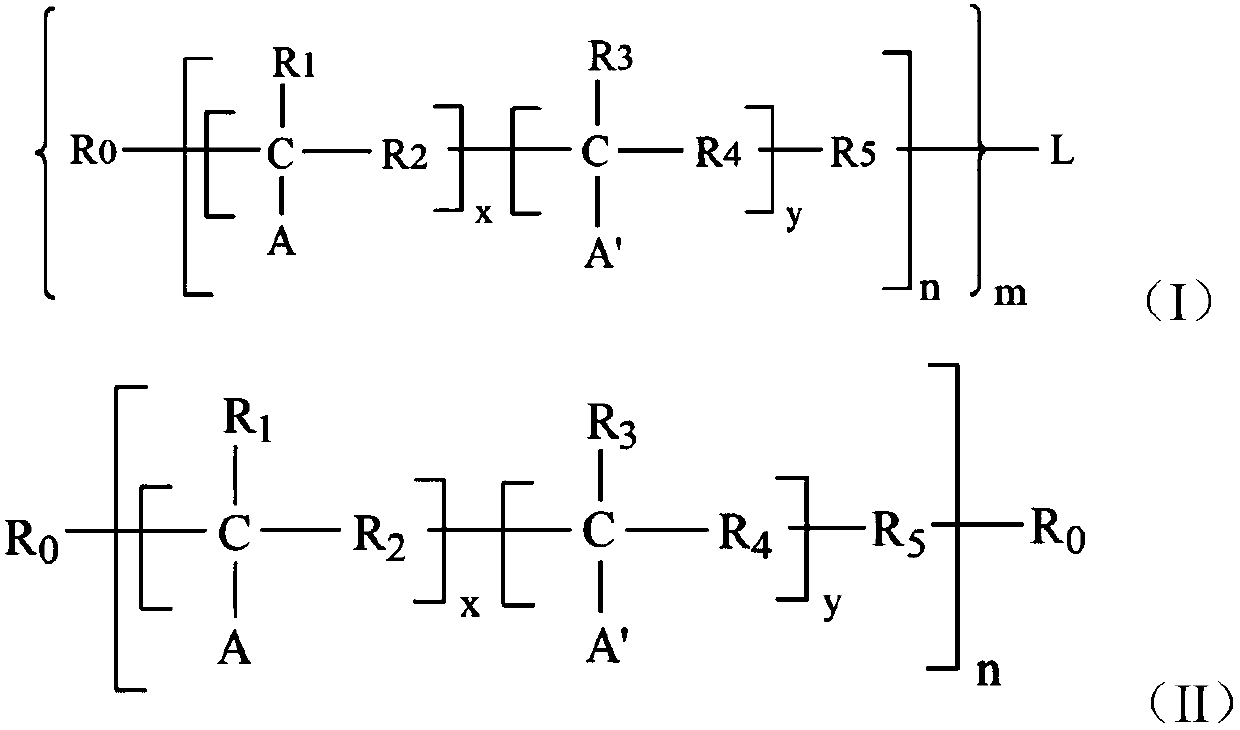

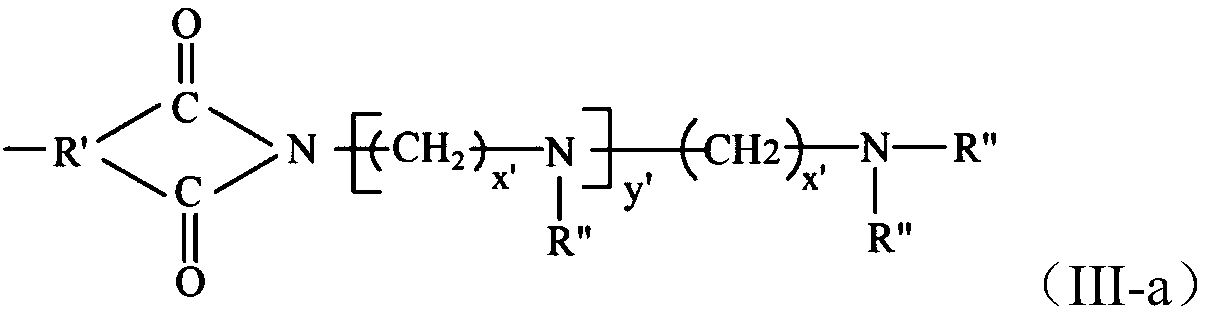

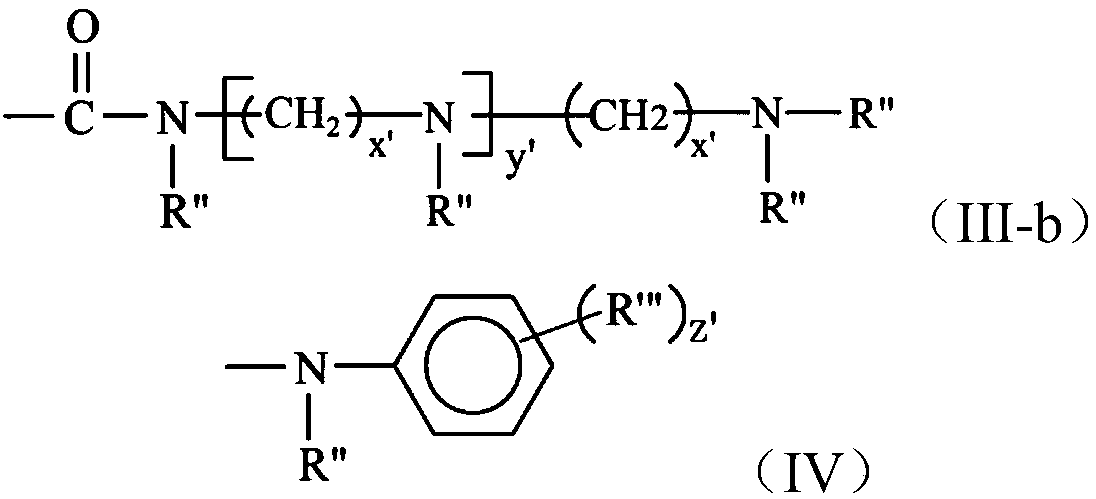

Method used

Image

Examples

Embodiment 1

[0089] The preparation of embodiment 1 ethylene-propylene copolymer viscosity index improver OCP

[0090] In a 2000 ml three-neck flask with temperature control, water cooling and stirring, add 100 grams of ethylene-propylene copolymer (Mw=182000, ethylene content 55%, purchased from China Petroleum Jilin Petrochemical Company), cut into 0.5cm 3 Then add 900 grams of 150SN (produced by Sinopec Gaoqiao Petroleum Company), heat up to 135 ° C, control the stirring to 300 rpm, and keep the temperature for 5 hours to obtain 1000 grams of viscosity index improver. Analysis Its weight-average molecular weight Mw=116310, and the ethylene content is 55%.

Embodiment 2

[0091] Embodiment 2 Preparation of dispersed ethylene-propylene copolymer viscosity index improver DOCP1

[0092] Take 100 grams (0.000086 mol) of the OCP viscosity index improver prepared in Example 1, put it into a 250 ml three-necked bottle with temperature control, water cooling, and stirring, protect it with nitrogen, and heat up to 85 ° C, then add the initiator to pass Add 1.0 g of benzoyl oxide, add 1.4 g of N-bromosuccinimide (0.0088 mol, dissolved in 6 g of carbon tetrachloride), control the reaction temperature at 75 ° C, react for 5 hours, then add 1.0 p-hydroxyaniline grams (0.009mol), reacted for 50 minutes, and then filtered to remove solid residue.

[0093] Add 1.5 g of azobisisobutyronitrile and 2.4 g (0.024 mol) of maleic anhydride to the brominated tackifier obtained above, and carry out grafting reaction at 150° C. for 2 hours. After the reaction, nitrogen was purged at 150° C. for 2 hours to remove unreacted maleic anhydride. Then control the temperature...

Embodiment 3

[0094] Embodiment 3 Preparation of dispersed ethylene-propylene copolymer viscosity index improver DOCP2

[0095] Take 100 grams (0.000086 mol) of the viscosity index improver obtained by the reaction in Example 1, add it into a 250 ml three-neck flask with temperature control, water cooling, and stirring, protect it with nitrogen, and heat up to 85 ° C, then add the initiator azo 1.2 grams of diisobutyronitrile, and 0.8 grams (0.01mol) of bromine water were added, the reaction temperature was controlled at 80°C, and the reaction was carried out for 4 hours, then 1.0 grams (0.009mol) of m-hydroxyaniline was added, and the reaction was carried out for 30 minutes, and then the solid residue was removed by filtration .

[0096] Add 1.2 grams of benzoyl peroxide and 2.8 grams (0.0286 mol) of maleic anhydride to the above brominated tackifier, and carry out grafting reaction at 150° C. for 2 hours. After the reaction, nitrogen was purged at 150°C for 2 hours to remove unreacted ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com