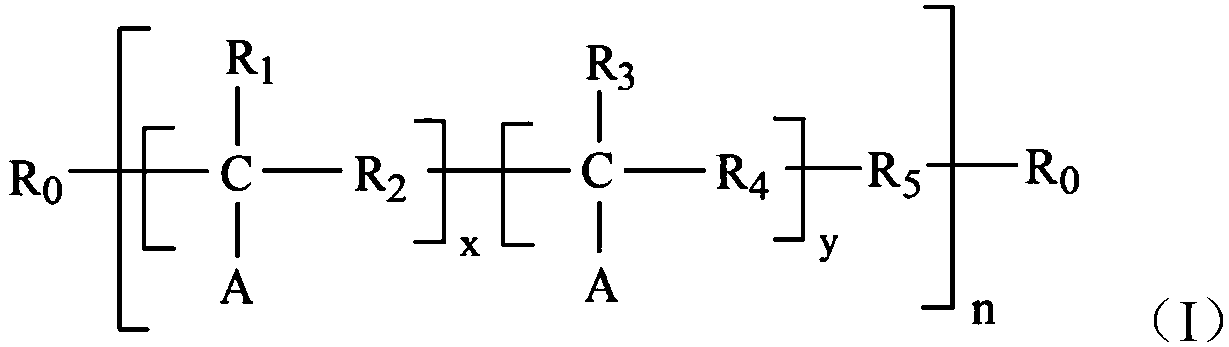

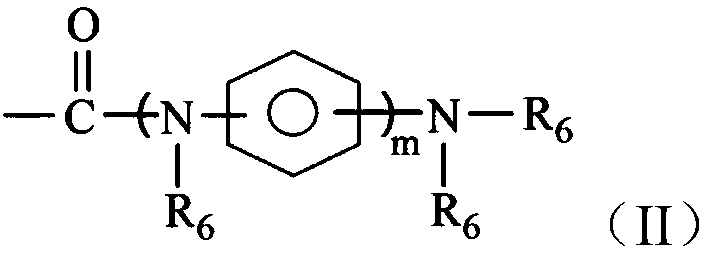

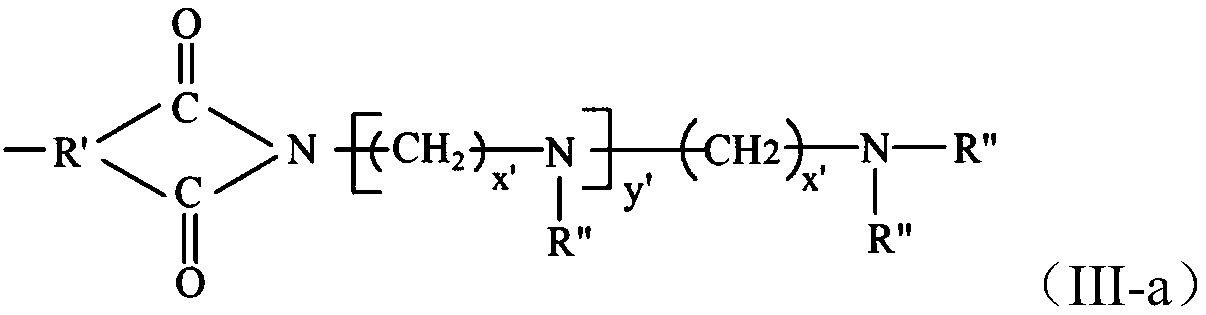

Viscosity index improver as well as preparation method and application thereof

A viscosity index improvement and integer technology, applied in the field of viscosity index improvers, can solve the problems of reducing ashless dispersants and adding large amounts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0119] The preparation of embodiment 1 dispersion type ethylene-propylene copolymer viscosity index improver DOCP-1

[0120] In a 500 ml pressure reactor with temperature control, water cooling and stirring, add 10 grams of ethylene-propylene copolymer (Mw=182000, (0.000055mol) ethylene content 58%, purchased from China Petroleum Jilin Petrochemical Company), cut into 0.5 cm 3 Then add 90 grams of 150SN (produced by Sinopec Gaoqiao Petroleum Company), and add 1.137 mg (0.001mol) of tetrakis(pentafluorophenyl)phenylferric chloride porphyrin (M=1136.7) (dissolved in 2 g In acetonitrile), after adding, the temperature was raised to 100°C, and air was introduced to keep the reaction pressure at 0.2MPa. After 6 hours of constant temperature reaction, the oxidation reaction was stopped, and the catalyst was separated by filtration to obtain a mixture of the oxidative degradation product of the copolymer and 150SN. The weight-average molecular weight of the oxidative degradation pro...

Embodiment 2

[0121] Embodiment 2 Preparation of dispersed ethylene-propylene copolymer viscosity index improver DOCP-2

[0122] In a 500 ml pressure reactor with temperature control, water cooling and stirring, add 10 grams of ethylene-propylene copolymer (Mw=182000, ethylene content 58%, purchased from China Petroleum Jilin Petrochemical Company), cut into 0.5cm 3 Then add 90 grams of 150SN (produced by Sinopec Gaoqiao Petroleum Company), add 0.7 mg of tetraphenylporphyrin ferric chloride (M=704.02, 0.001mol) (dissolved in 1.5 grams of acetonitrile), and heat up to 110 ℃, feed air, keep the reaction pressure at 0.3 MPa, keep the temperature for 4 hours, stop the oxidation reaction, filter and separate the catalyst, and obtain the mixture of the oxidative degradation product of the copolymer and 150SN, and the weight average molecular weight of the oxidative degradation product is measured as 110600 , the acid value is 0.20mgKOH / g. Add 0.034 g of p-diphenylamine (M=169.22) to the mixture ...

Embodiment 3

[0123] Embodiment 3 Preparation of dispersed ethylene-propylene copolymer viscosity index improver DOCP-3

[0124] In a 500 ml pressure reactor with temperature control, water cooling and stirring, add 10 grams of ethylene-propylene copolymer (Mw=182000, ethylene content 58%, purchased from China Petroleum Jilin Petrochemical Company), cut into 0.5cm 3 Then add 90 grams of 150SN (produced by Sinopec Gaoqiao Petroleum Company), and add 1.5 mg (0.0013mol) of tetrakis(pentafluorophenyl)phenylferric chloride porphyrin (M=1136.7) (dissolved in 3 g acetonitrile), heated up to 100°C, and fed air, kept the reaction pressure at 0.4MPa, kept the temperature for 7 hours, stopped the oxidation reaction, filtered and separated the catalyst, and obtained the mixture of the oxidized degradation product of the copolymer and 150SN, and measured the oxidized The weight average molecular weight of the degradation product is 123000, and the acid value is 0.15.mgKOH / g. Add 0.022 g of p-hydroxyani...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com