Railway ballastless track bed steel bar resistance testing method

A resistance test, ballast bed technology, applied in the measurement of resistance/reactance/impedance, roads, tracks, etc., can solve the problems of increasing the number of connected steel bars, affecting the construction efficiency of ballastless track, increasing manpower and material resources, etc., to achieve Save time, save time and improve construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In the following, the method of the present invention will be described in more detail by taking the measurement of the resistance of steel bars in a ballastless ballast bed (6.00 meters in length) as an example, so as to facilitate the understanding of those skilled in the art.

[0020] Railway ballastless ballast bed reinforcement resistance test method of the present invention comprises following specific steps:

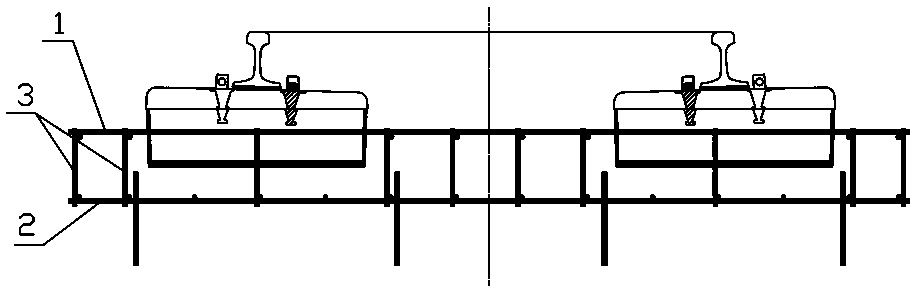

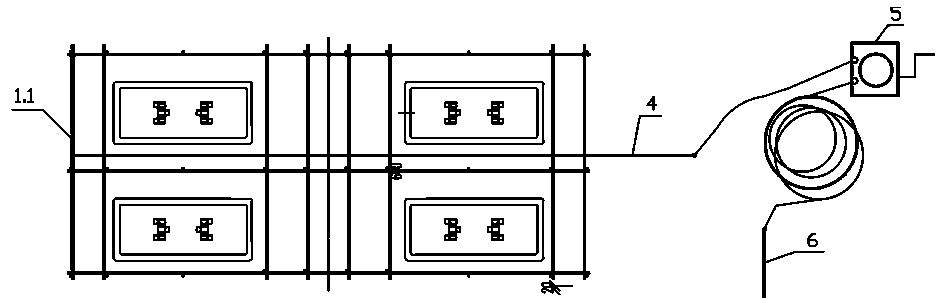

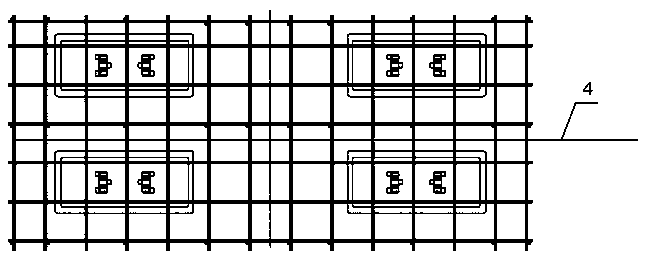

[0021] In the first step, according to the design requirements, the upper steel frame 1 (φ16 steel bar), the lower steel frame 2 (φ14 steel bar) and the erecting bar 3 (φ10 Steel bars) are all connected with insulating cards, and implanted into the backfill layer of the tunnel through φ16 steel bars (implantation depth 150mm). figure 1 shown; figure 2 is the top view (plane) view of the upper steel bar 1, image 3 is the top view (plane) view of the lower reinforcement bar 2;

[0022] Choose the φ1.6 iron wire as the measuring iron wire 4 (under normal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com