Construction Method of Cantilever Casting Corrugated Steel Web Skew Box Girder Bridge by Hanging Basket Method

A technology of corrugated steel webs and construction methods, which is applied in the direction of buildings, bridges, bridge construction, etc., can solve the problems of low construction efficiency and complex structure of hanging baskets, so as to improve construction efficiency, shorten construction period, and save time for laying tracks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The construction method of the cantilevered corrugated steel web oblique box girder bridge of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments:

[0037] For ease of description, the bridge extension direction is set as the longitudinal direction extending along the front-rear direction, and the bridge width direction is set as the transverse direction extending along the left-right direction. The triangular hanging basket includes the main truss system, anchor system, bottom basket system, suspension system, and walking system.

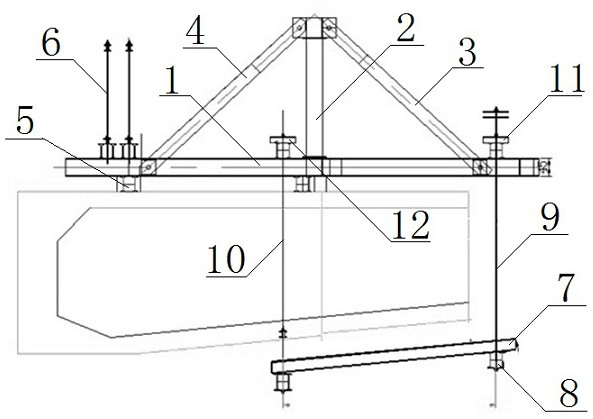

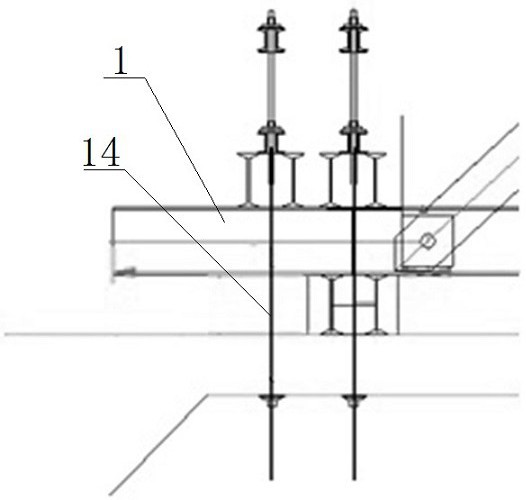

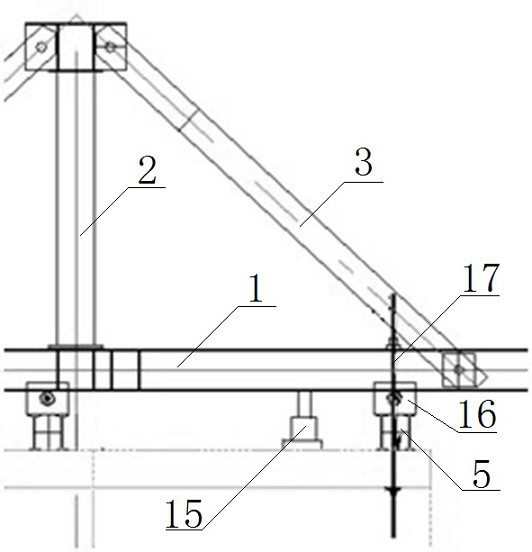

[0038] Such as figure 1 As shown, the main truss system includes three sets of main trusses and transverse connecting beams fixedly connected between adjacent main trusses. The main truss includes a main longitudinal beam 1 extending along the extension direction of the bridge, a vertical rod 2 arranged longitudinally in the middle of the main longitudinal be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com