Energy consumption self-recovery pressure type anchor rod and construction method thereof

A self-restoring, pressure-type technology, applied in the direction of foundation structure engineering, sheet pile walls, protection devices, etc., can solve the problems of residual strain that cannot be self-adjusted and recovered, and cannot effectively consume energy, etc., to achieve simple and feasible technology and improve the stress state , Ease of construction and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

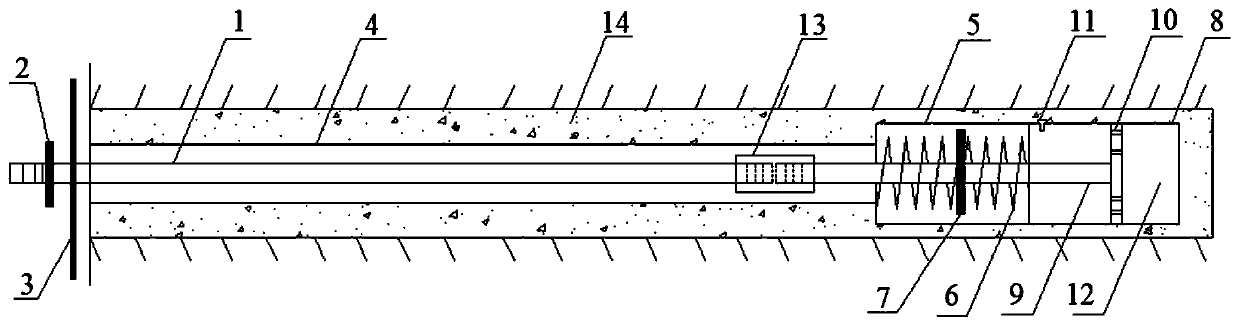

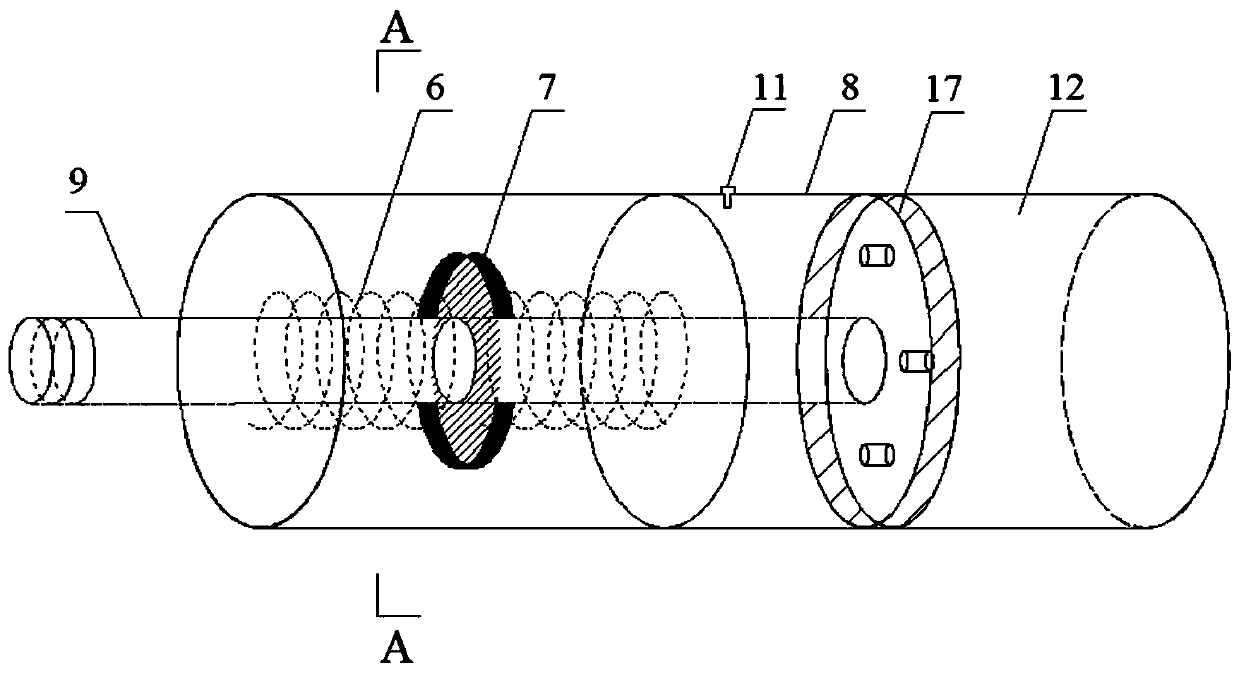

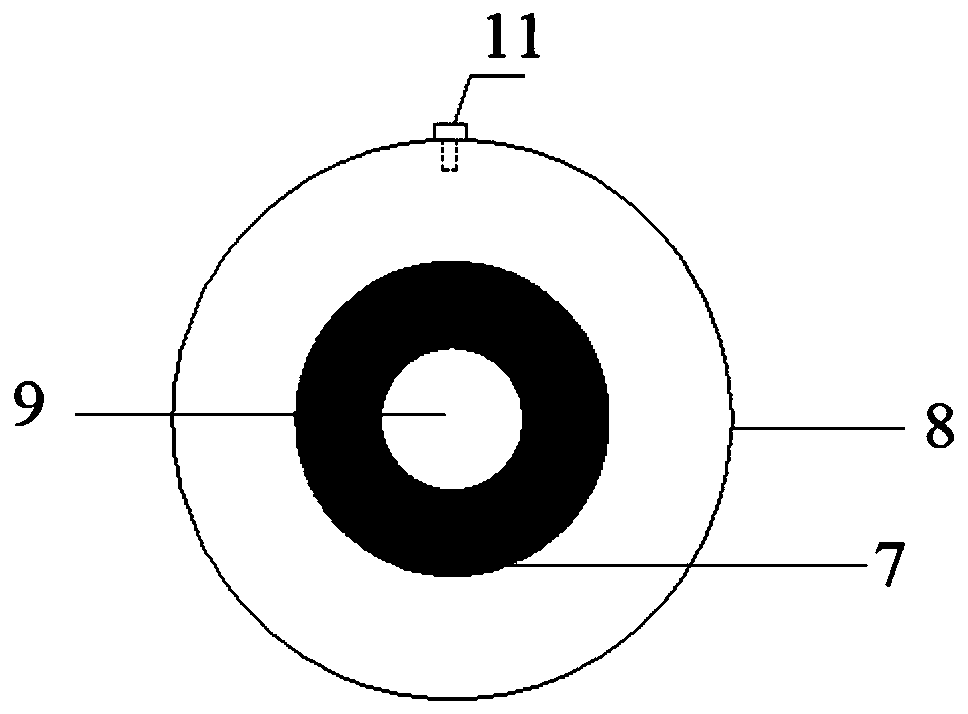

[0043] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

[0044]The present invention aims at the deficiency of the pressure-type anchor rod under the action of dynamic load, and proposes an energy-consuming self-restoring pressure-type anchor rod. The anchor rod has the function of yielding deformation, increasing the deformable displacement of the rod body during work, and the energy-consuming self-restoring device works It can effectively consume energy and buffer during the force transmission process of the anchor rod. After the load is over, the potential energy absorbed by the device can restore the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com