Pump bearing fault diagnosis method

A fault diagnosis and pump bearing technology, applied in measuring devices, instruments, character and pattern recognition, etc., can solve problems such as misjudgment and cannot be effectively identified, and achieve the effect of eliminating high-frequency interference, convenient operation and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

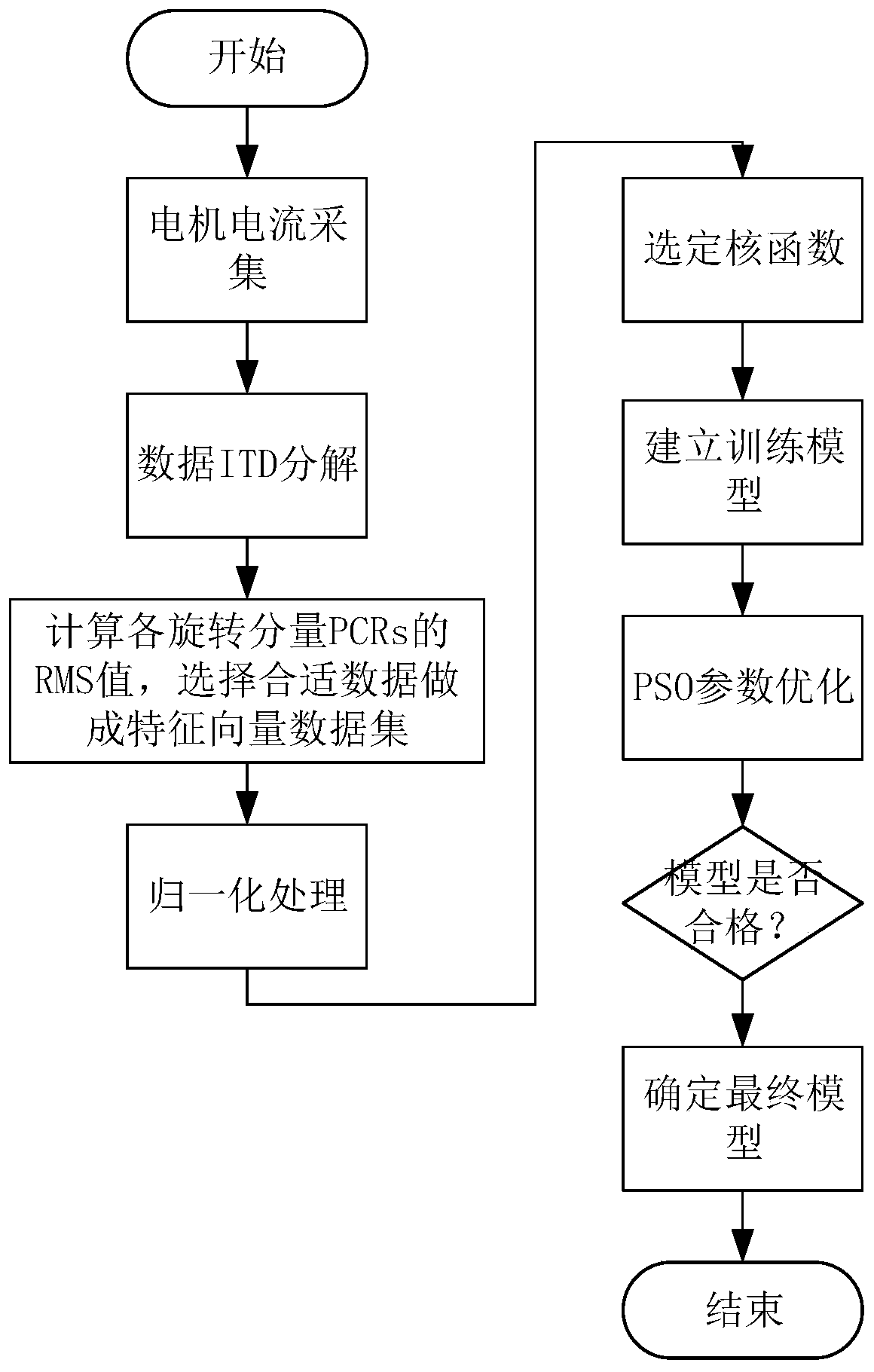

[0036] like figure 1 As shown, the embodiment of the present invention discloses a method for pump bearing fault diagnosis, comprising the following steps:

[0037] The signal detection module collects the vibration signal, and eliminates high-frequency interference through the conditioning circuit;

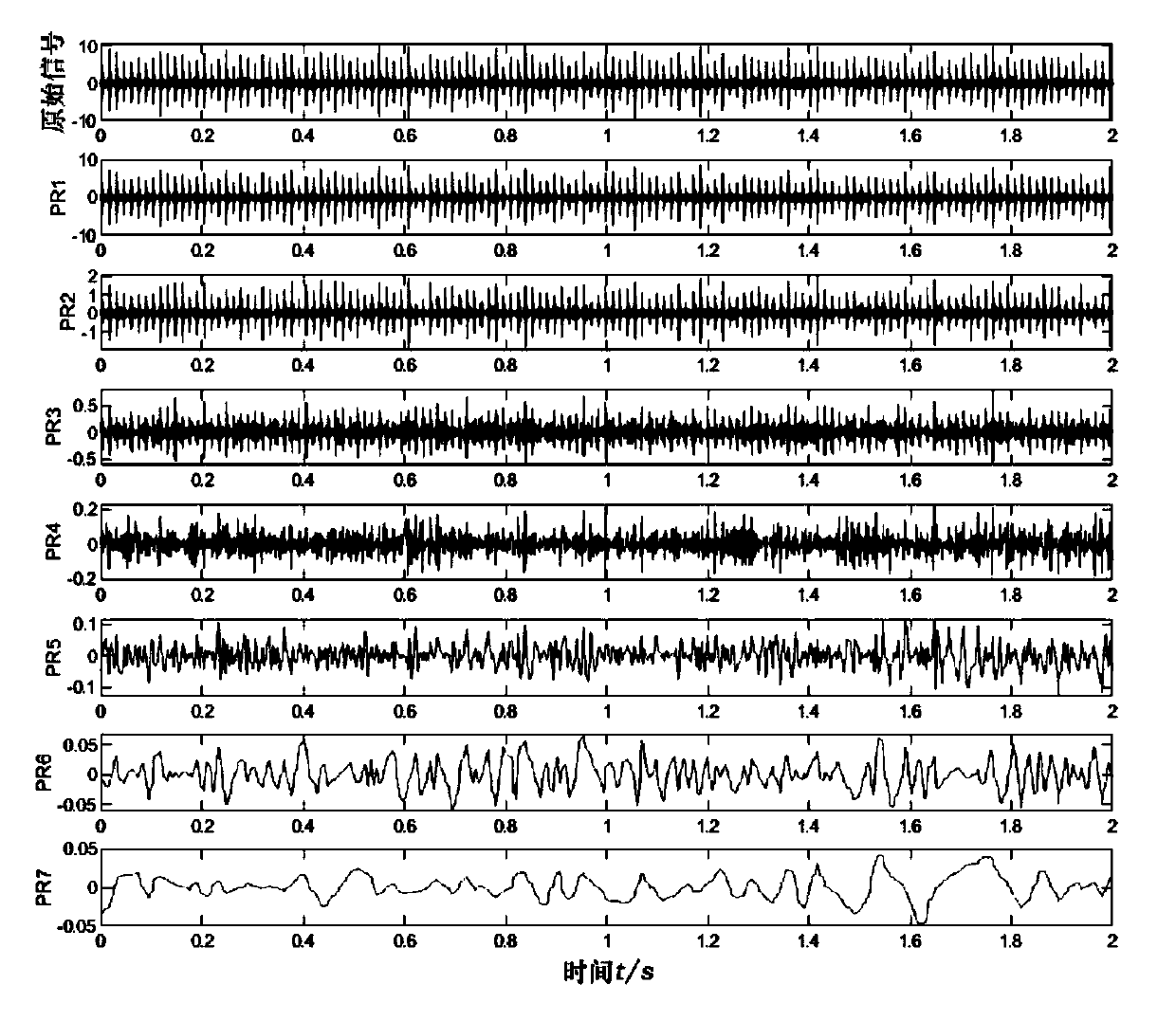

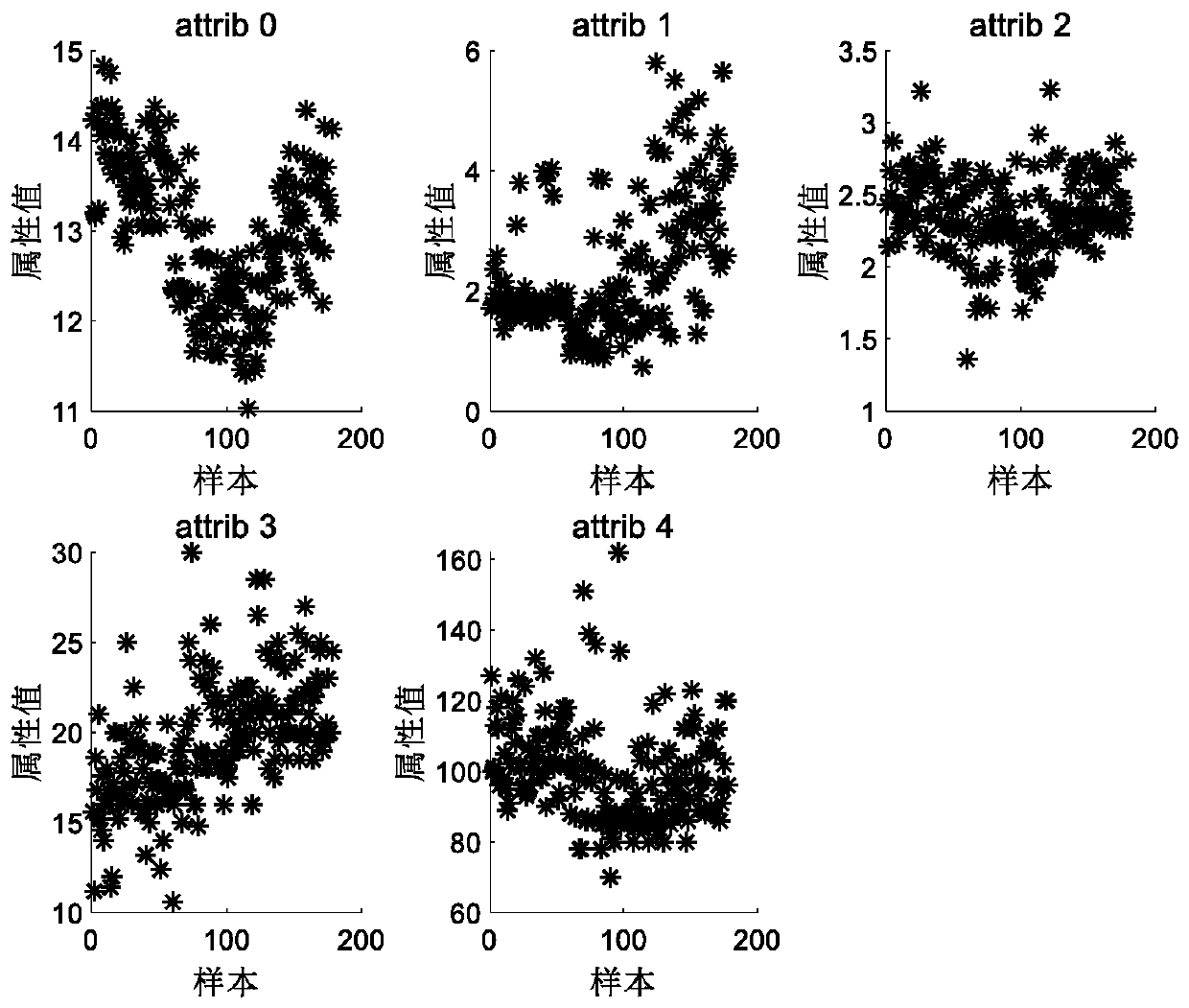

[0038] Decomposing the collected fault signal multiple times, once decomposing to obtain a baseline signal and an inherent rotation component, extracting the RMS of a plurality of said inherent rotation components (PCRs) as the feature value to form the fault characteristic data set X under the rotation frequency, Wherein, the decomposition of the fault signal adopts the intrinsic time scale decomposition (ITD) method;

[0039] Perform normalization processing to described fault characteristic data set, and construct fault classification model and carry out pattern recognition to bearing fault signal, wherein, described pattern recognition comprises training stage and recognitio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com