Distributed management lithium iron phosphate battery pack

A lithium iron phosphate battery and lithium iron phosphate technology, applied in battery circuit devices, arrangement of multiple synchronous batteries, collectors, etc., can solve the problem of high temperature requirements in the working environment, poor high-rate discharge performance, large footprint, etc. problems, to achieve the effect of high maintenance cost, long cycle life and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

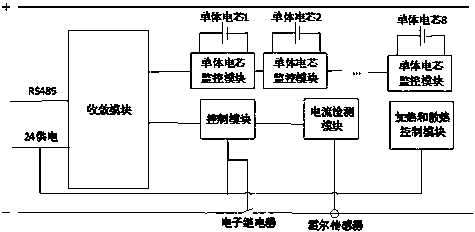

[0023] The invention consists of N (N is a natural number) 3.2V100Ah lithium iron phosphate battery, a single battery monitoring module, a current monitoring module, a control module and a convergence module (see figure 1 ). "Single cell monitoring module" is responsible for collecting cell voltage and cell pole temperature, and has balance function and balance failure protection function. It has a high-precision 24-bit AD acquisition chip; the current detection module cooperates with the Hall sensor to detect current. All the signals collected or detected by the "single cell monitoring module" and "current detection module" are uploaded to the "convergence module", which is responsible for data analysis, storage, and calculation of SOC and SOH, with local alarm function , the "convergence module" has multi-level alarm settings. If there is a non-serious alarm, the local a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com