Coating composition, electro-conductive film, and liquid crystal display panel

一种液晶显示面板、导电性膜的技术,应用在导电涂料、绝缘载体上的导电层、分散在不导电无机材料中的导电材料等方向,能够解决漏光显示品质、降低等问题,达到触摸面板性能提高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0101] Hereinafter, the present invention will be specifically described based on examples. However, the present invention is not limited by the following examples. In addition, unless otherwise specified, the following "parts" and "%" are mass standards.

[0102] Table 1 shows main materials used in Examples.

[0103] [Table 1]

[0104]

[0105]

[0106] "ELCOM V-3560" manufactured by Nikke Catalyst Chemicals Co., Ltd. was prepared as a chain-like ATO particle dispersion liquid. The chain-like ATO particle dispersion "ELCOM V-3560" is a mixed dispersion of 19.2 parts of chain-like ATO particles, 1.3 parts of a silica-based dispersant, 70.0 parts of ethanol, and 9.5 parts of isopropanol.

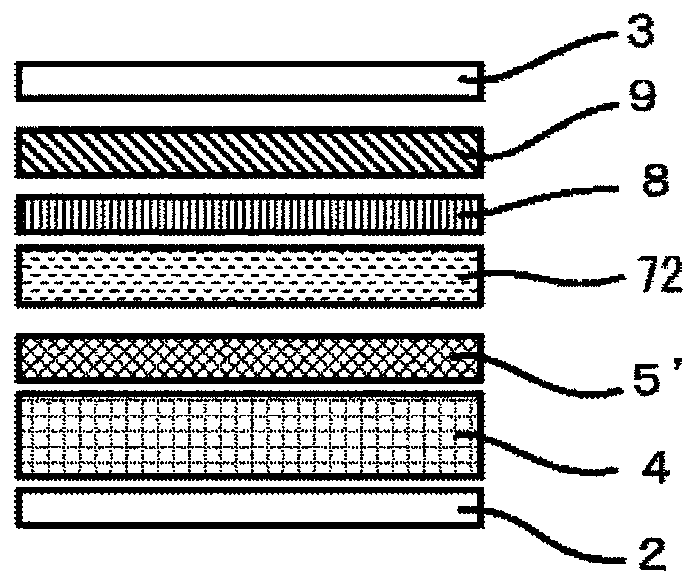

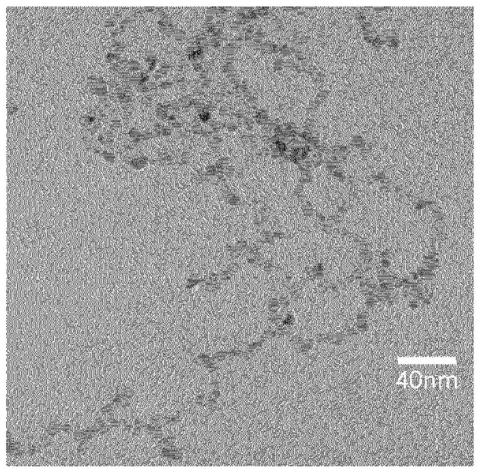

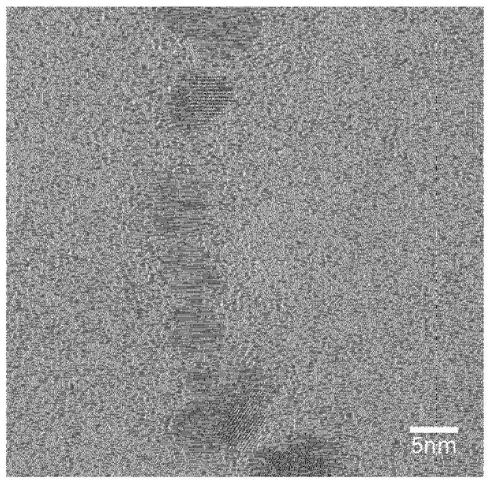

[0107] figure 2 and image 3 It is a transmission electron microscope (TEM) photograph of the chain-shaped ATO particle used for the above-mentioned chain-shaped ATO particle dispersion liquid. refer to figure 2 and image 3 , it can be seen that the above-mentioned ATO particle...

manufacture example

[0109]

[0110] Add 20.5 parts of conductive ATO particles "SN100P" (trade name) manufactured by Ishihara Sangyo Co., Ltd., 2.0 parts of dispersant "BYK180" (trade name) manufactured by BYK Chemical Japan Co., Ltd., and 77.5 parts of isobutylene to a plastic bottle. Alcohol (solvent) was dispersed with a paint conditioner (manufactured by Toyo Seiki Co., Ltd.) for 2 hours using zirconia beads with a diameter of 0.3 mm, and stirred to prepare a dispersion liquid A.

Synthetic example 1

[0112] Add an appropriate amount of tetramethoxysilane to the solution with an appropriate amount of low-boiling point alcohol, hydrochloric acid catalyst, and water, drop a small amount each time, and stir for a certain period of time while controlling the temperature and pH, then deacidify with an ion exchange resin It was processed to prepare an alkoxysilane oligomer solution having a solid content concentration of 10 wt % and a weight average molecular weight of 5,200.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com