Transmission device for reciprocating rotation of ultrasonic three-dimensional probe transducer and application method thereof

A transmission device, reciprocating rotation technology, applied in transmission device, application, ultrasonic/sonic/infrasonic diagnosis and other directions, can solve the problems of large impact force, low transmission efficiency, uneven force, etc., to achieve good movement speed stability, The effect of high stability of equipment operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

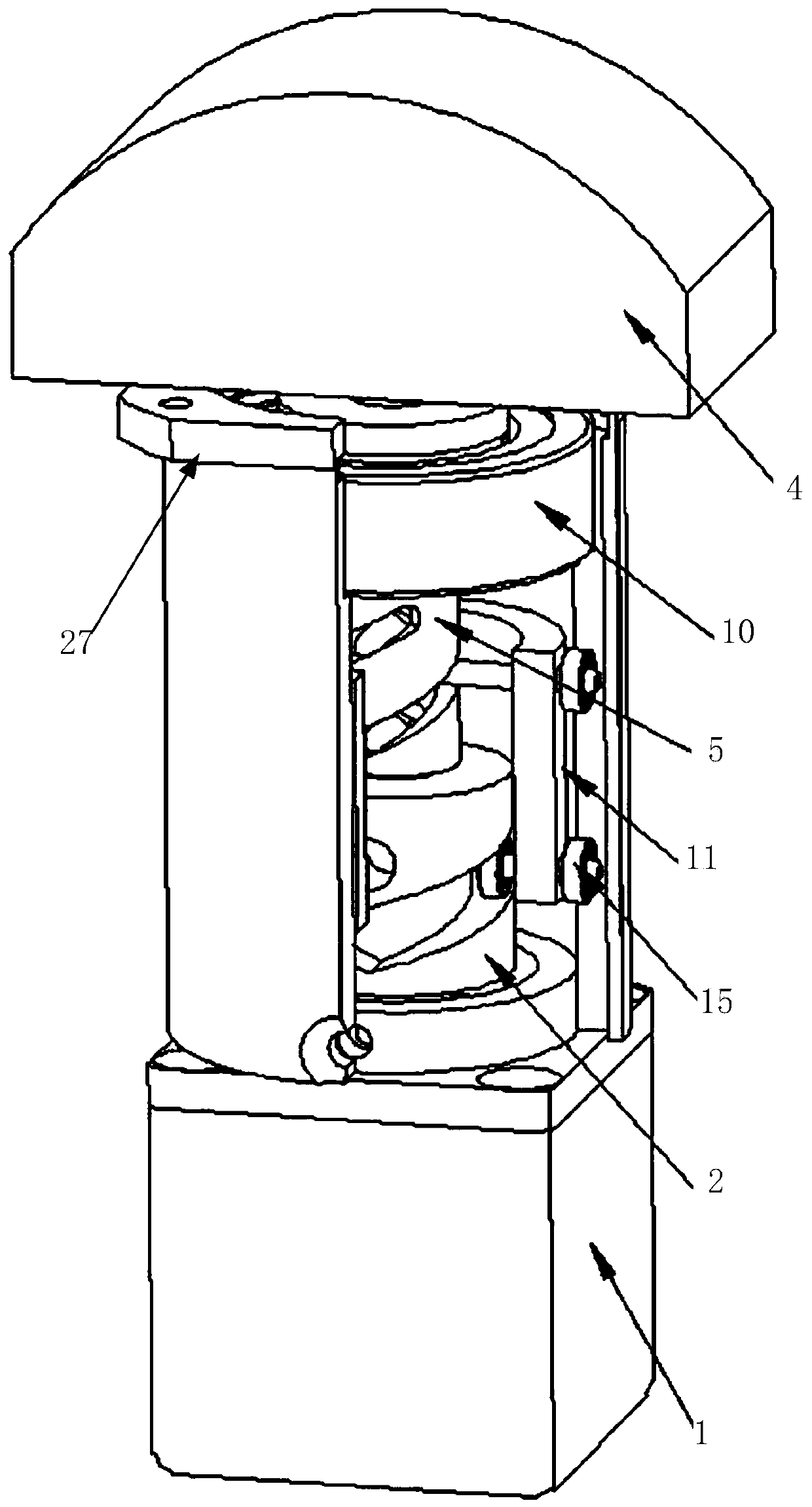

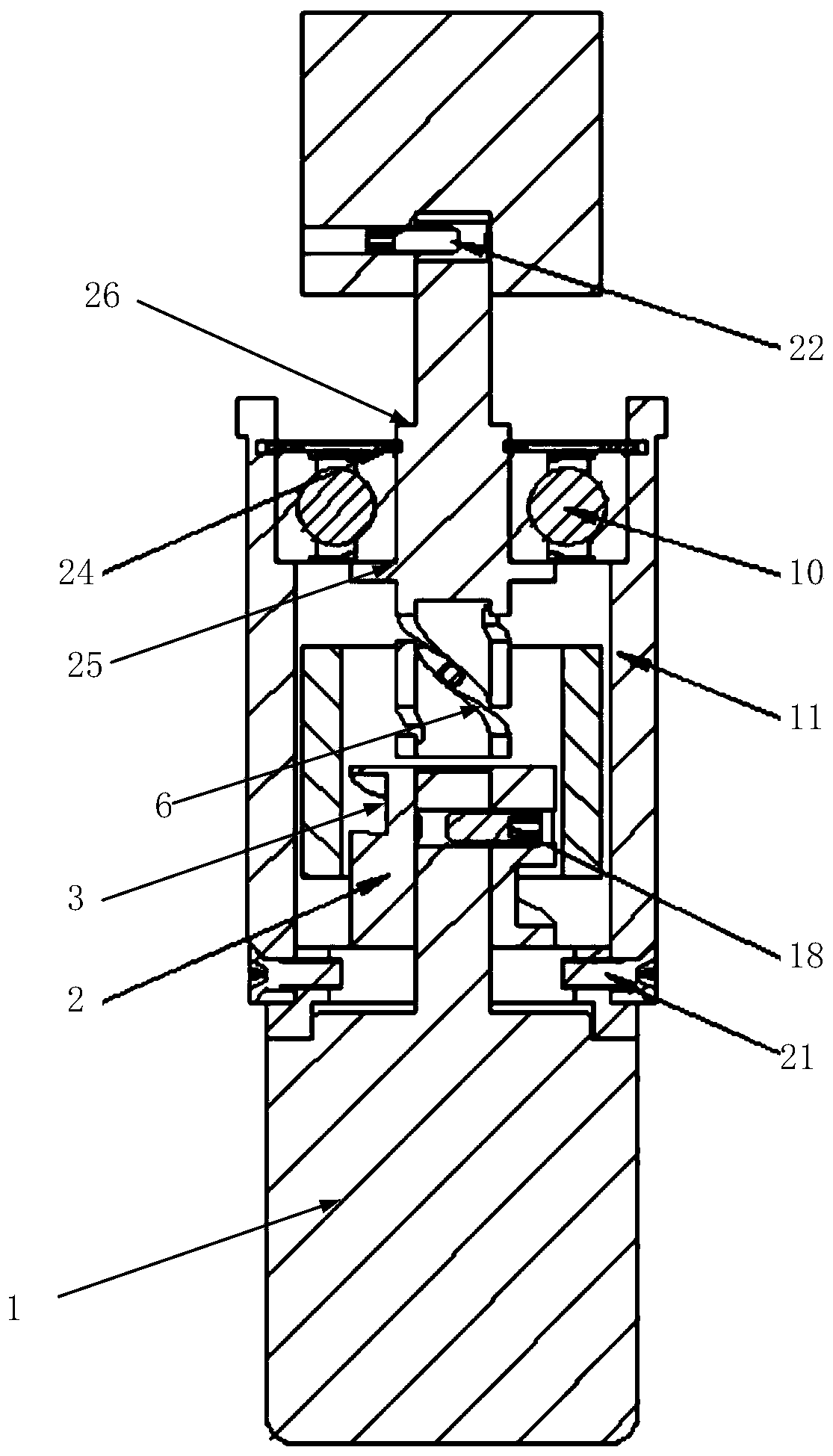

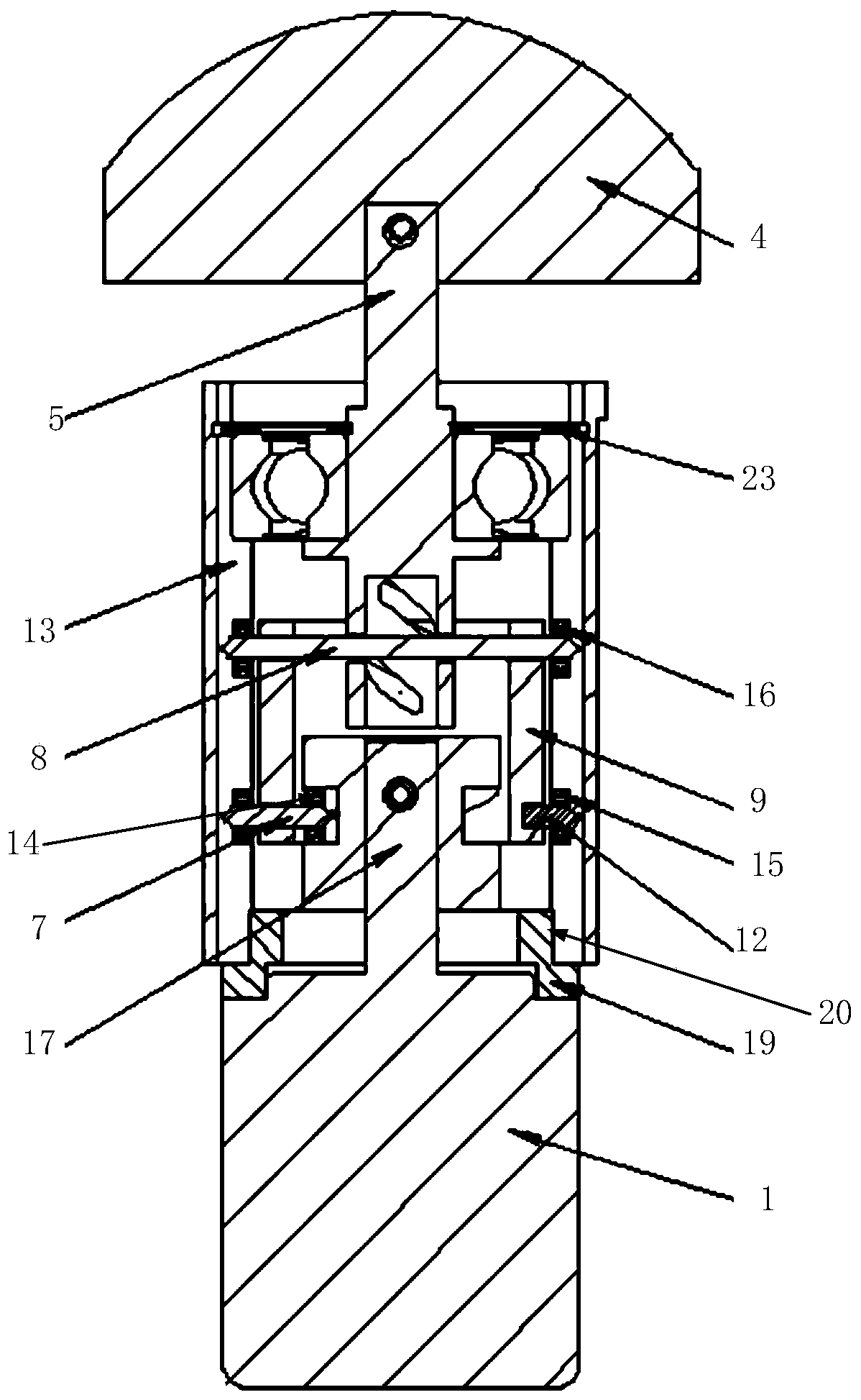

[0069] Embodiment: The motor shaft is tightly connected with the cylindrical cam screw; the sliding connecting rod, the rolling connecting rod, and the positioning connecting rod are installed with bearings, and are tightly matched with the connecting rod bushing; the rolling connecting rod bearing is matched with the cylindrical cam groove, and the sliding connecting rod The rod passes through the screw shaft and cooperates with the spiral groove; the 4 bearings on the connecting rod bushing are limited in the chute of the housing; the screw shaft passes through the bearing, and the bearing is limited in the housing by the shaft and the hole with a circlip; the screw shaft and The transducer is fastened and connected by screws; the shell is connected with the motor connection seat by screws, and the motor connection seat is connected by screws; Linear reciprocating motion together with the connecting rod bushing, sliding connecting rod, and positioning connecting rod; the scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com