Manufacturing method of microgel stent based on flexible mold capillary folding technology

A flexible mold and manufacturing method technology, applied in biochemical equipment and methods, cell culture supports/coatings, microorganisms, etc., can solve the problems of difficult to form three-dimensional microgel scaffolds, difficult to control scaffold morphology and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0022] A method for manufacturing a microgel support based on flexible mold capillary folding technology, comprising the following steps:

[0023] 1) Design of the flexible mold: In order to prepare microgel scaffolds with different shapes, the shape of the flexible mold is optimally designed using topological knowledge. The flexible mold includes a flexible substrate, and one side of the flexible substrate is provided with periodic grabbing Structure; expanding the outer surface of the designed microgel scaffold to a two-dimensional plane is the shape of the flexible mold;

[0024] 2) Preparation of flexible mold:

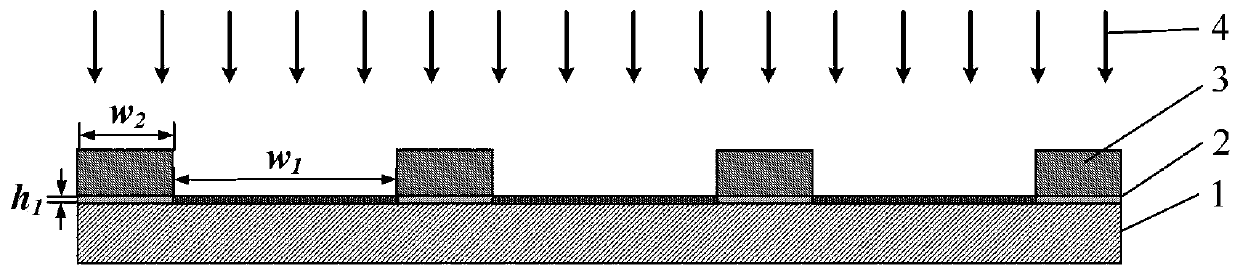

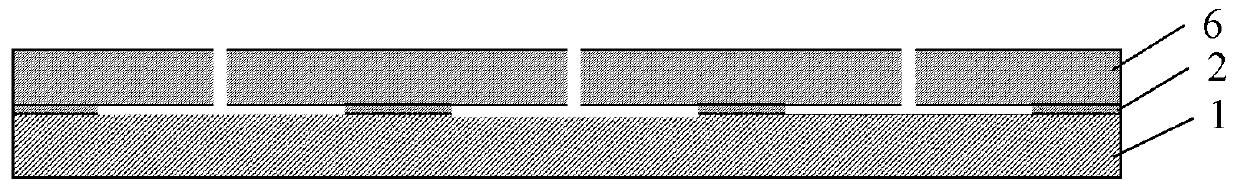

[0025] 2.1) Spin-coat the first layer of photoresist 2 on silicon wafer or glass wafer 1, its thickness h 1 It is in the micron scale, and then pre-baked on a hot plate; through the top ultraviolet light 4, it is exposed through the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com