An ultra-long pier thickening device for a large-wall-thick seamless steel pipe and its application method

A technology of seamless steel pipe and pier thickness, which is applied in forging/pressing/hammer devices, heating/cooling equipment, forging furnaces, etc., which can solve the straightness difference and bending of the heating part of the pipe end, which affects the product processing pass rate and affects the processing efficiency And other problems, to achieve the effect of improving processing efficiency, not easy to bend, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

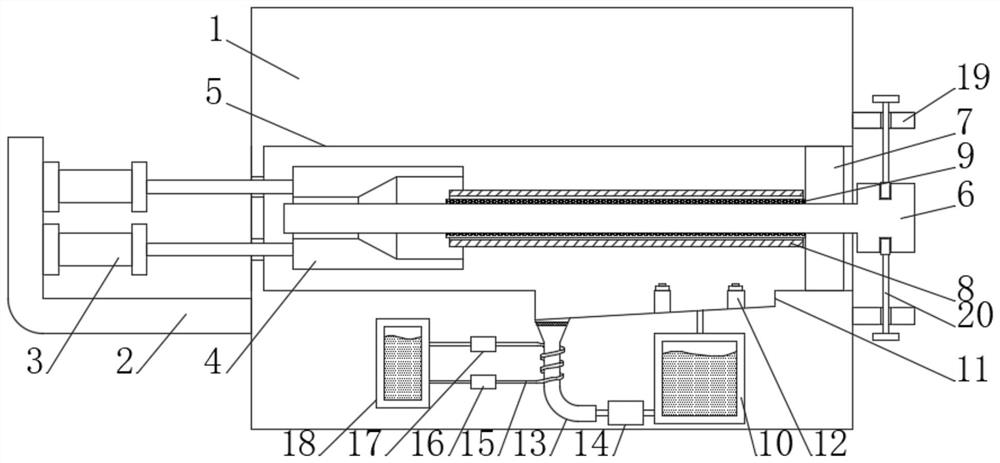

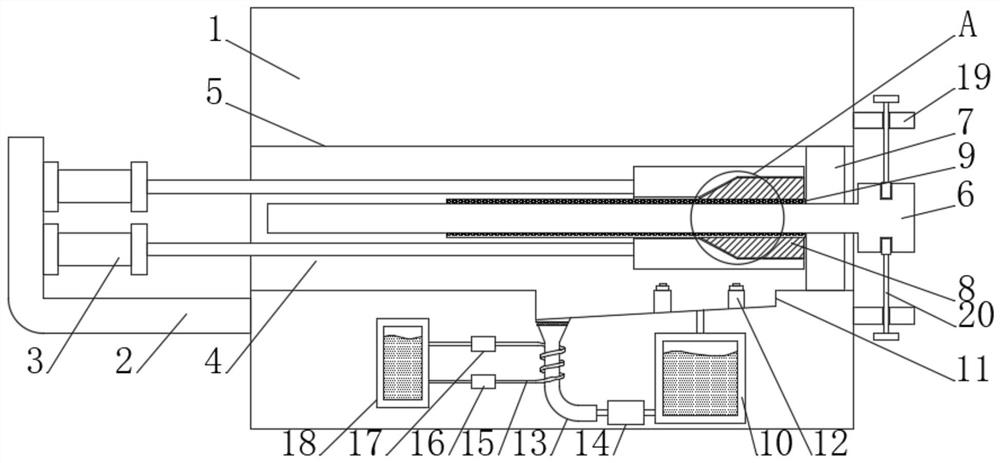

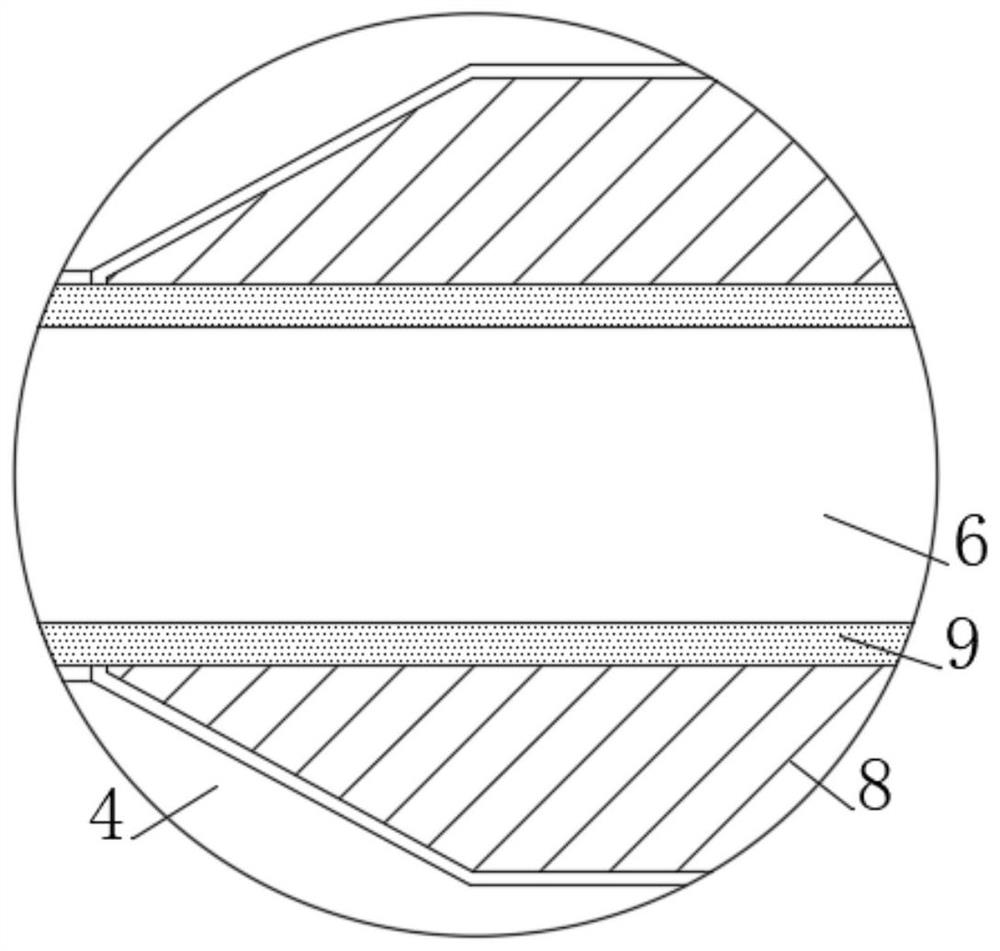

[0037] see Figure 1-6 , a large-wall thick seamless steel pipe ultra-long thick pier device and its use method, comprising an intermediate frequency induction furnace 1, the left end of the intermediate frequency induction furnace 1 is fixedly connected with an L-shaped mounting plate 2, and the inner wall of the L-shaped mounting plate 2 is fixedly connected with a pair of cylinders 3. The output end of the cylinder 3 is fixedly connected with the movable mold 4, and the intermediate frequency induction furnace 1 is equipped with a heating chamber 5, the movable mold 4 is located in the heating chamber 5, and the heating chamber 5 is equipped with a core rod, and the diameter of the core rod is as thick as required The inner diameter of seamless steel pipe 8 is generally 1.8mm-2mm smaller than the inner diameter. The end diameter of the core rod is generally 68% of the final outer diameter that needs to be thickened. The outer end of the core rod is fixedly connected with a f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com