Laser material nicking machine capable of adsorbing and removing scraps

A laser material and scoring machine technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of affecting the service life of the scoring machine, reducing the efficiency of glass scoring, and insufficient technical considerations, so as to avoid Effects of friction, prolonging service life and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

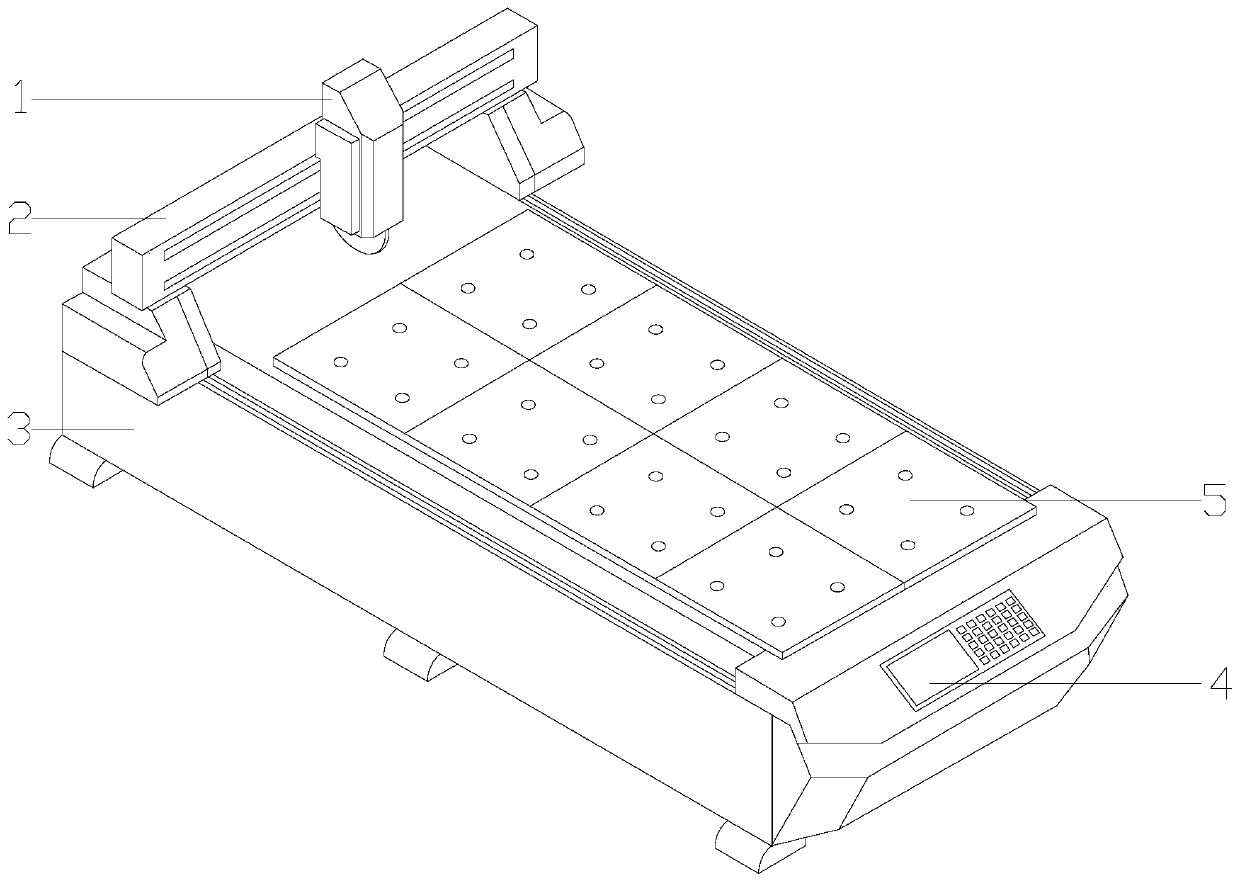

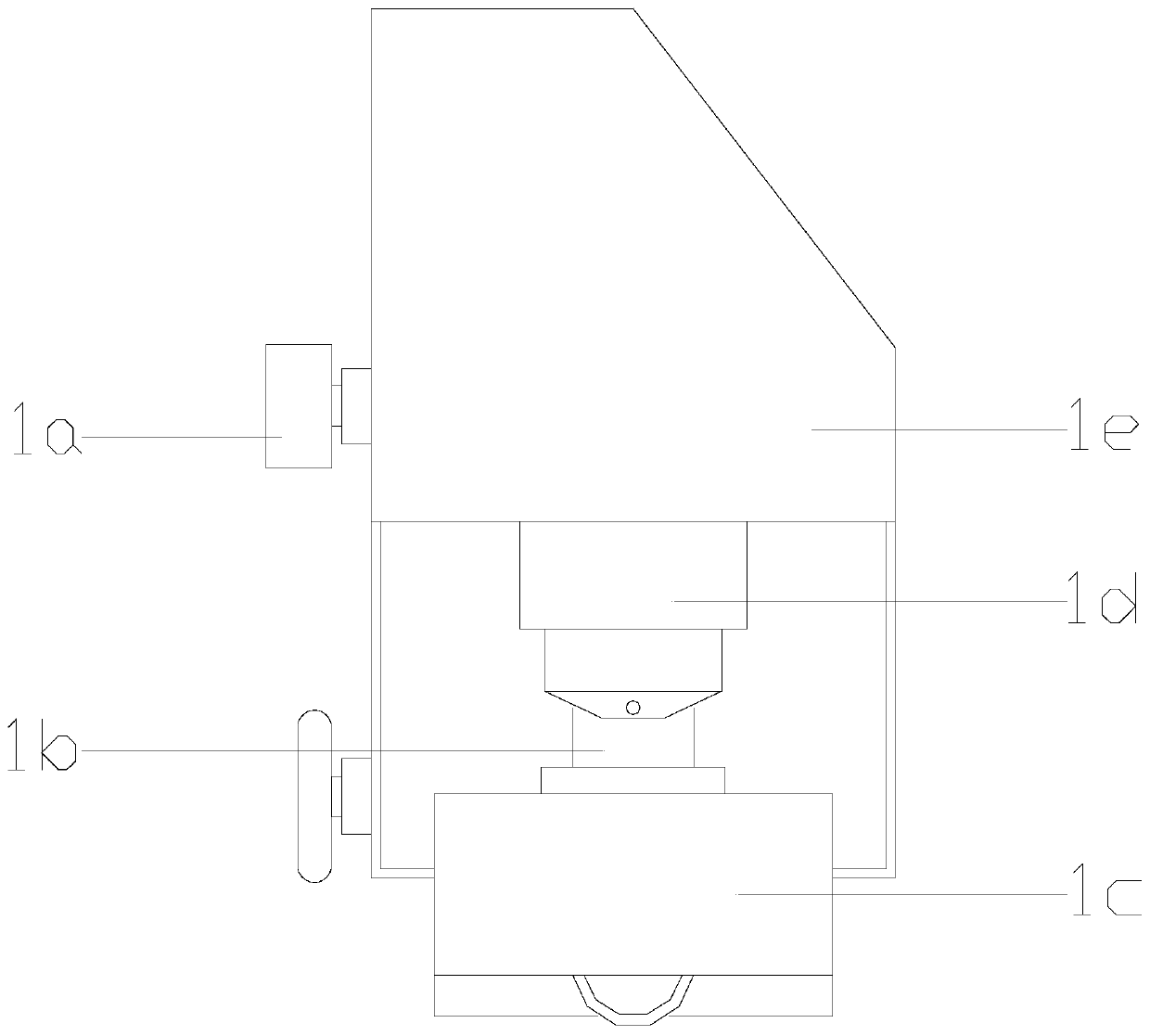

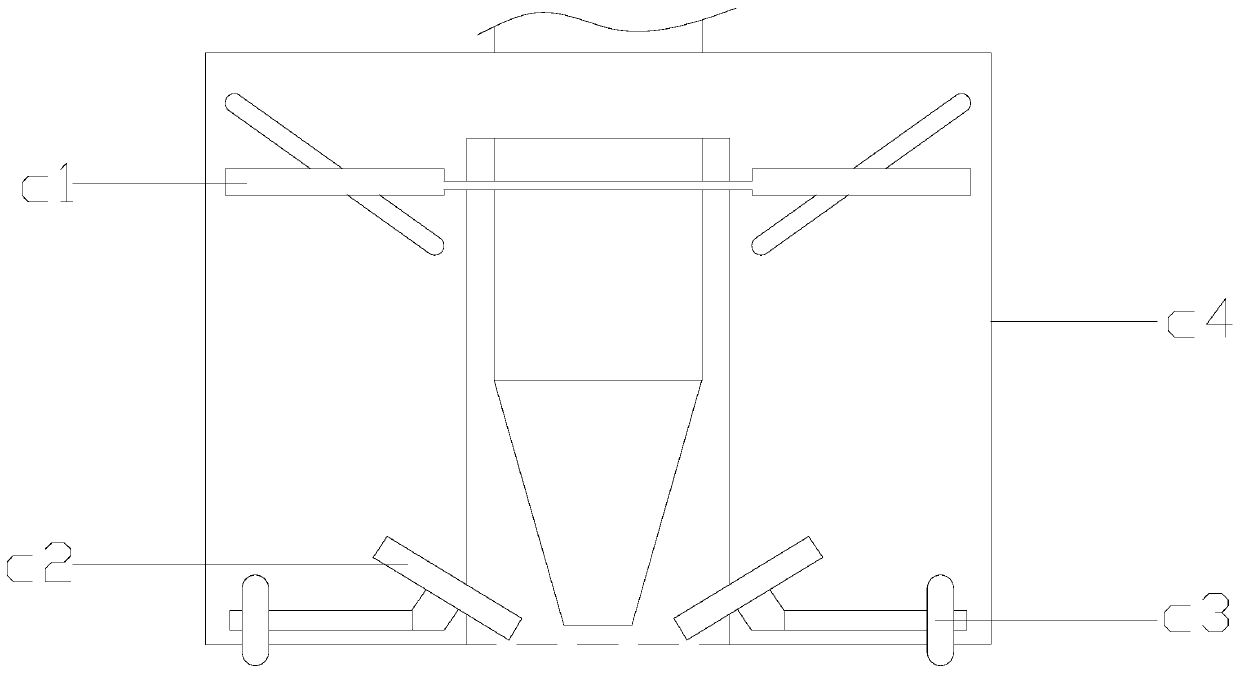

[0023] see Figure 1-Figure 2 , the present invention provides a laser material scoring machine for absorbing and removing debris. 3 is a rectangular structure and is installed horizontally on the ground. The bottom of the sliding adjustment rod 2 is matched with the guide rail on the equipment support platform 3 by using a gap. The intelligent control system 4 is nested on the surface of the equipment support platform 3 and is connected with the equipment support platform 3 are electrically connected, the glass fixing platform 5 is located above the equipment support platform 3 and the bottom surface is attached to the upper surface of the equipment support platform 3, the left side of the scoring tool holder 1 is in clearance fit with the sliding adjustment rod 2, and the scoring tool holder 1 adopts clearance fit. The marking knife holder 1 is composed of a driving roller 1a, a glass scoring knife 1b, a debris remover 1c, a rotation adjustment device 1d, and a knife holder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com