Automatic feeding and discharging device for parts and using method

A technology for automatic loading and unloading of parts and parts, applied in metal processing, etc., can solve the problems of high labor intensity and low efficiency of manual clamping of workpieces, and achieve the effects of low production cost, reduced number of workers, and reliable action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following will be described in detail in conjunction with the technical solutions in the embodiments of the present invention:

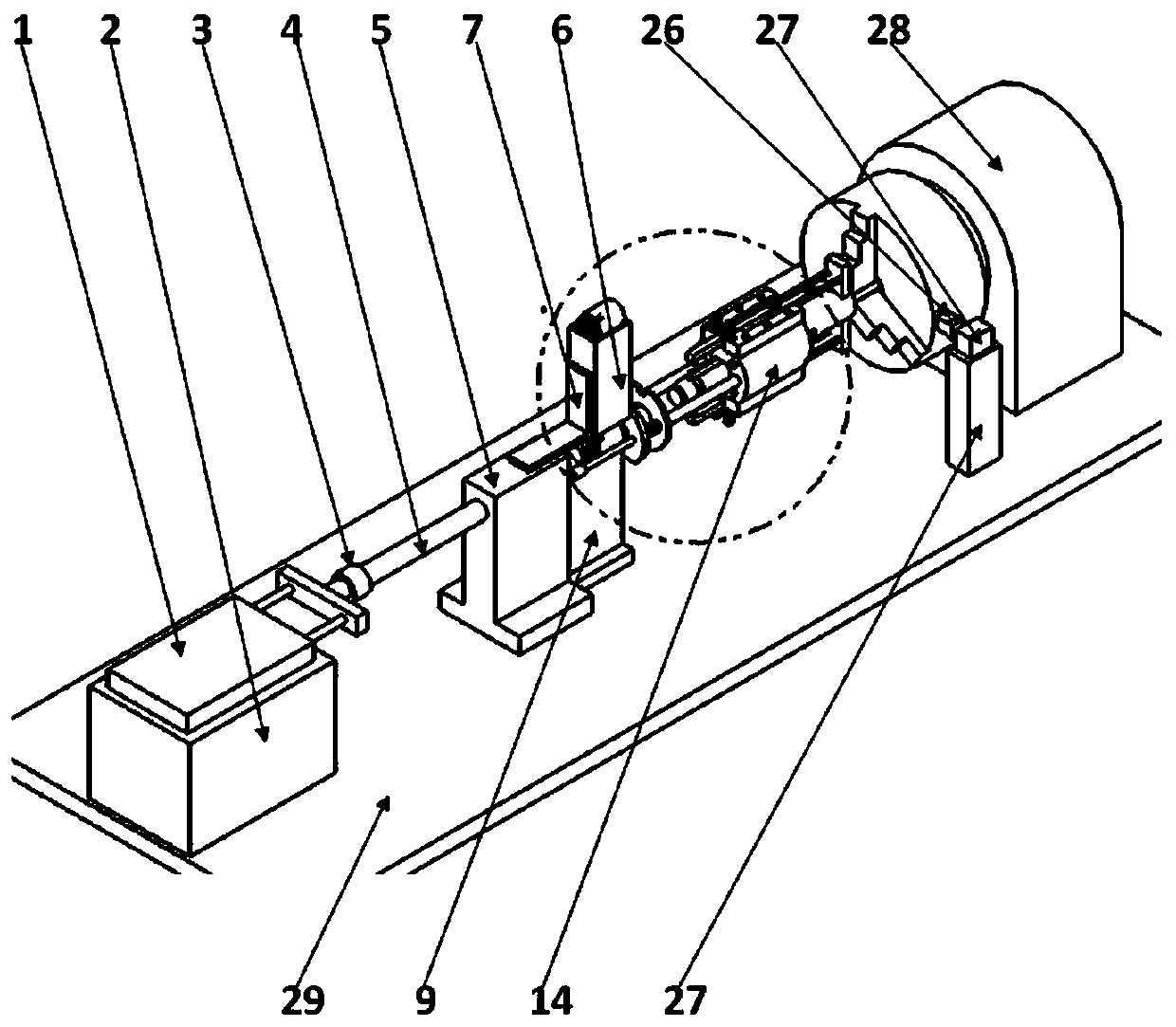

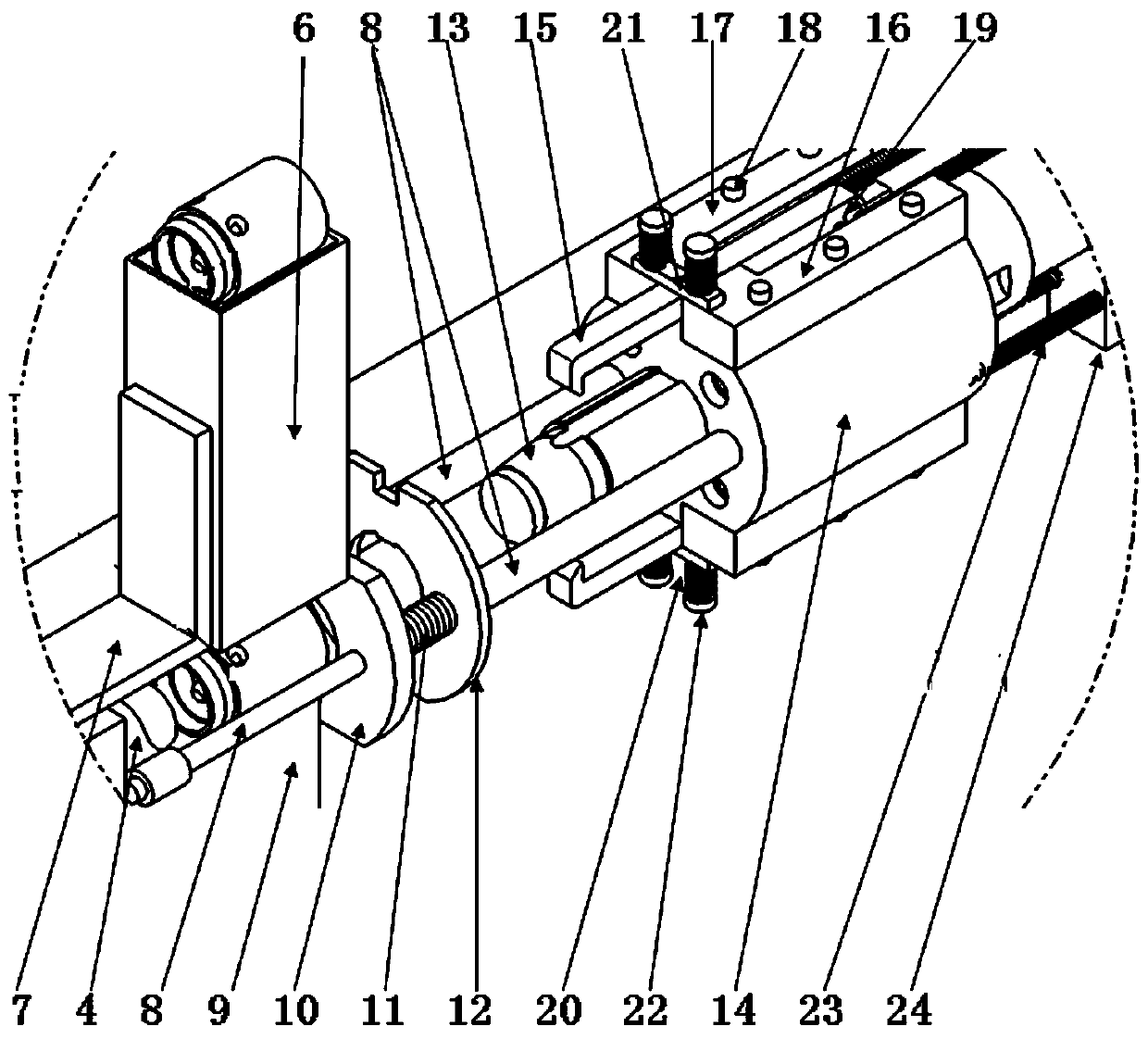

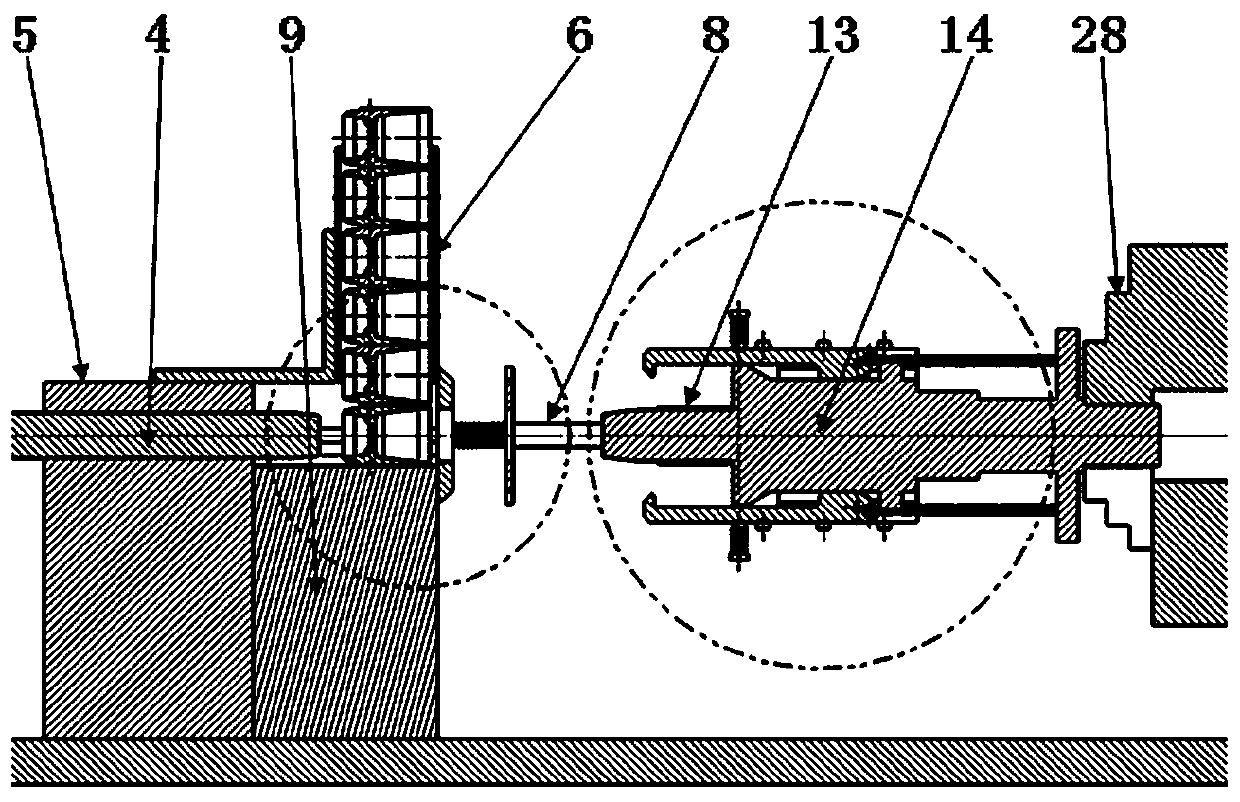

[0033] see Figure 1-16 As shown, an automatic loading and unloading device for parts includes a workbench 29, on which a power mechanism, an actuator, a signal mechanism and a clamping mechanism are sequentially designed from left to right on the workbench 29, and the power mechanism includes a cylinder 1 and a clamping mechanism. Cylinder installation frame 2, the actuator includes hopper 6, hopper bracket 7, push rod 4, coupling 3, guide rod 8, material receiving block 9, front baffle 10, baffle spring 11, rear baffle 12 , positioning column 13, body 14, buckle 15, buckle left track 16, buckle right track 17, track screw 18, buckle pin 19, buckle spring 20, buckle pressure plate 21, buckle bolt 22, pull Spring 23, extension spring fixed frame 24, described clamping mechanism comprises the electric indexing head 28 of numerical control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com