Environment-friendly flame-retardant plastic as well as preparation method and application thereof

A flame retardant plastic and environmental protection technology, applied in the field of plastics, can solve the problems of poor flame retardant effect and little impact on the mechanical properties of polyester plastics, and achieve the effects of small impact on mechanical properties, good flame retardant effect, and high mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] An environmentally friendly flame-retardant plastic is prepared from the following raw materials in parts by weight: 100 parts of polyester, 10 parts of flame retardant, 2 parts of plasticizer, 2 parts of antioxidant, and 0.8 part of anti-ultraviolet agent.

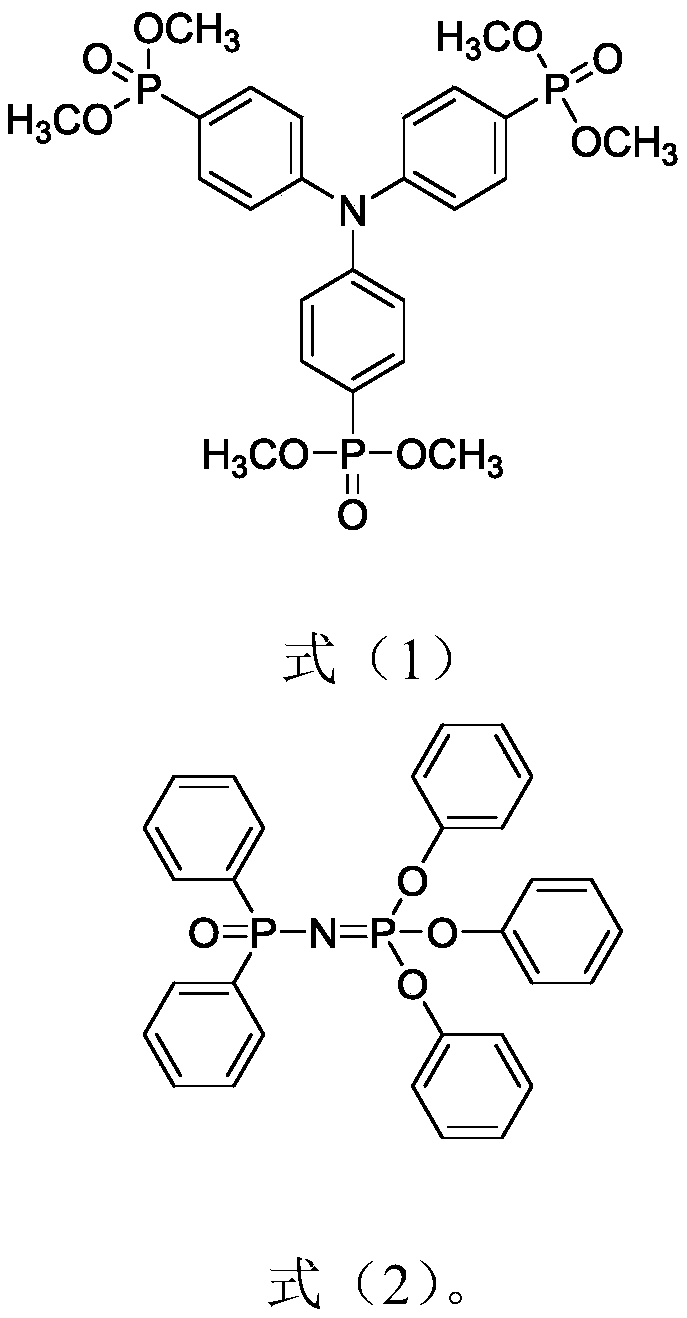

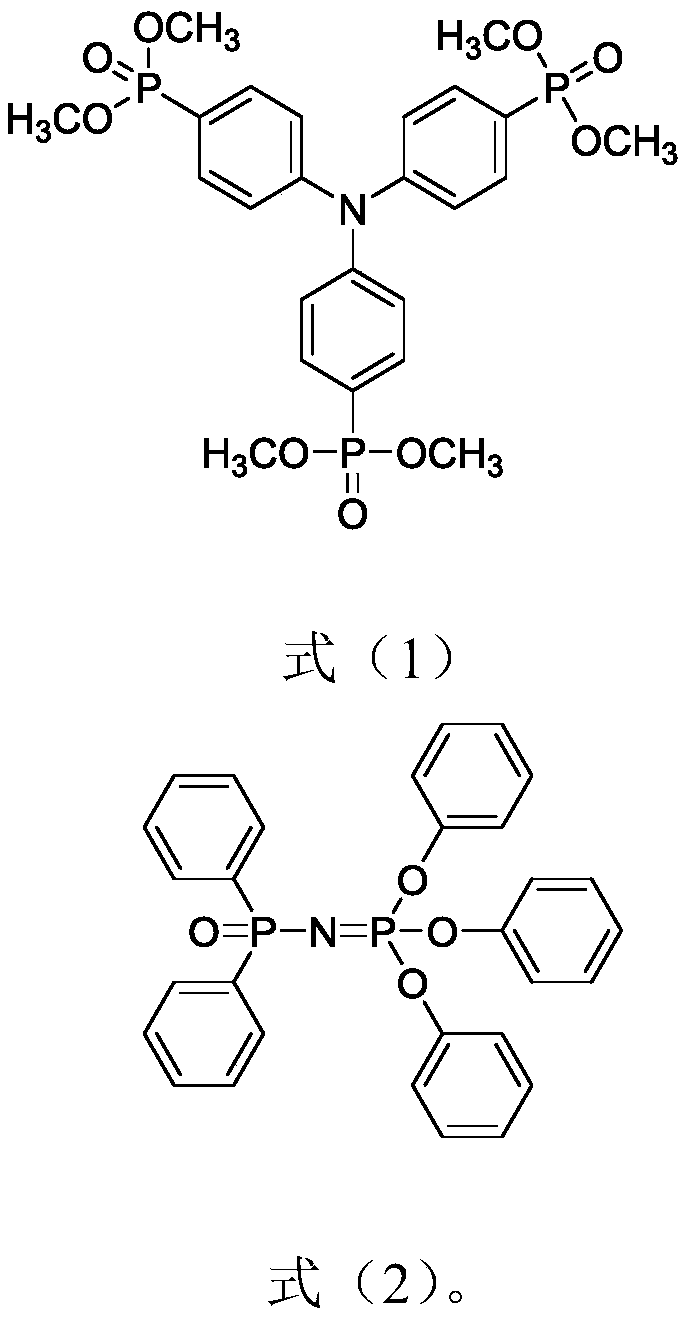

[0048] The flame retardant consists of flame retardant A and flame retardant B.

[0049] The flame retardant is composed of flame retardant A and flame retardant B in a mass ratio of 1:5.

[0050] The plasticizer is di-n-octyl phthalate.

[0051] The antioxidant is 2,6-di-tert-butylphenol.

[0052] The anti-ultraviolet agent is 2-hydroxyl-4-n-octyloxybenzophenone.

[0053] The preparation method of environment-friendly flame-retardant plastic comprises the following steps:

[0054] (1) Dry the polyester in an oven at a drying temperature of 110°C and a drying time of 4 hours;

[0055] (2) The screw barrel of the injection molding machine and the injection mold are preheated, the temperature of the screw barrel ...

Embodiment 2

[0060] It is basically the same as Embodiment 1, the difference is only in:

[0061] The flame retardant is composed of flame retardant A and flame retardant B in a mass ratio of 1:6.

Embodiment 3

[0063] It is basically the same as Embodiment 1, the difference is only in:

[0064] The flame retardant is composed of flame retardant A and flame retardant B in a mass ratio of 1:7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com