Preparation method of a new austenitic stainless steel material with high strength and hydrogen embrittlement resistance

An austenitic stainless steel, high-strength technology, applied in the field of anti-hydrogen embrittlement of stainless steel, can solve the problems of hydrogen-induced embrittlement, valve seat damage, poor closure and other problems that cannot be ignored, achieve easy factory operation, improve strength and strength and the effect of improving the resistance to hydrogen embrittlement

Active Publication Date: 2021-05-18

ZHEJIANG UNIV OF TECH

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although the original austenitic stainless steel will not produce obvious hydrogen embrittlement in the hydrogen environment, the problem of hydrogen-induced embrittlement after strain strengthening cannot be ignored

So far, there have been many accidents caused by hydrogen-induced damage to stainless steel in high-pressure hydrogen systems at home and abroad, such as: microcracks in the diaphragm of diaphragm-type hydrogen compressors, cracks in spring tubes (strain-strengthened stainless steel) of high-pressure hydrogen pressure gauges, high-pressure hydrogen The seat of the valve (strain strengthened stainless steel) is damaged, resulting in poor closure

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

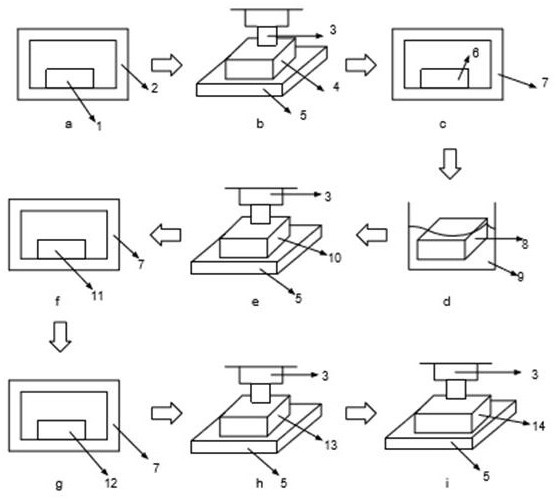

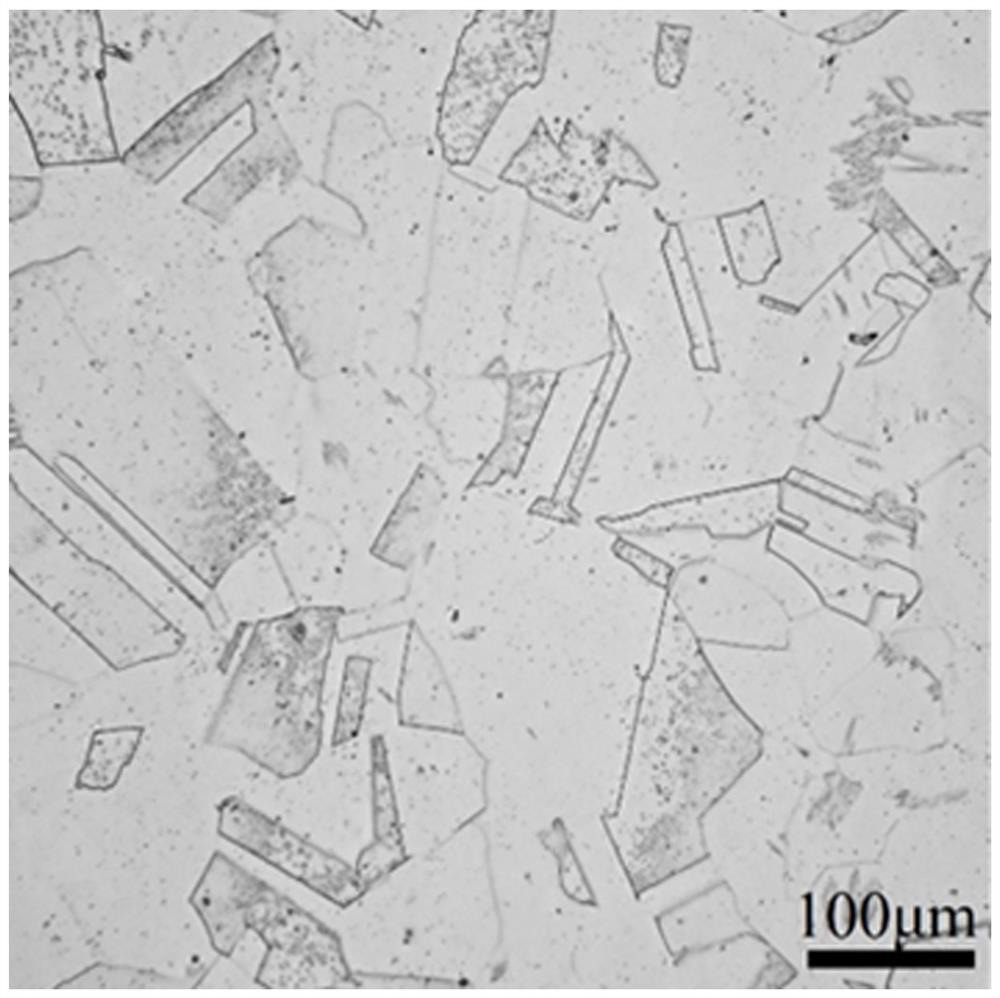

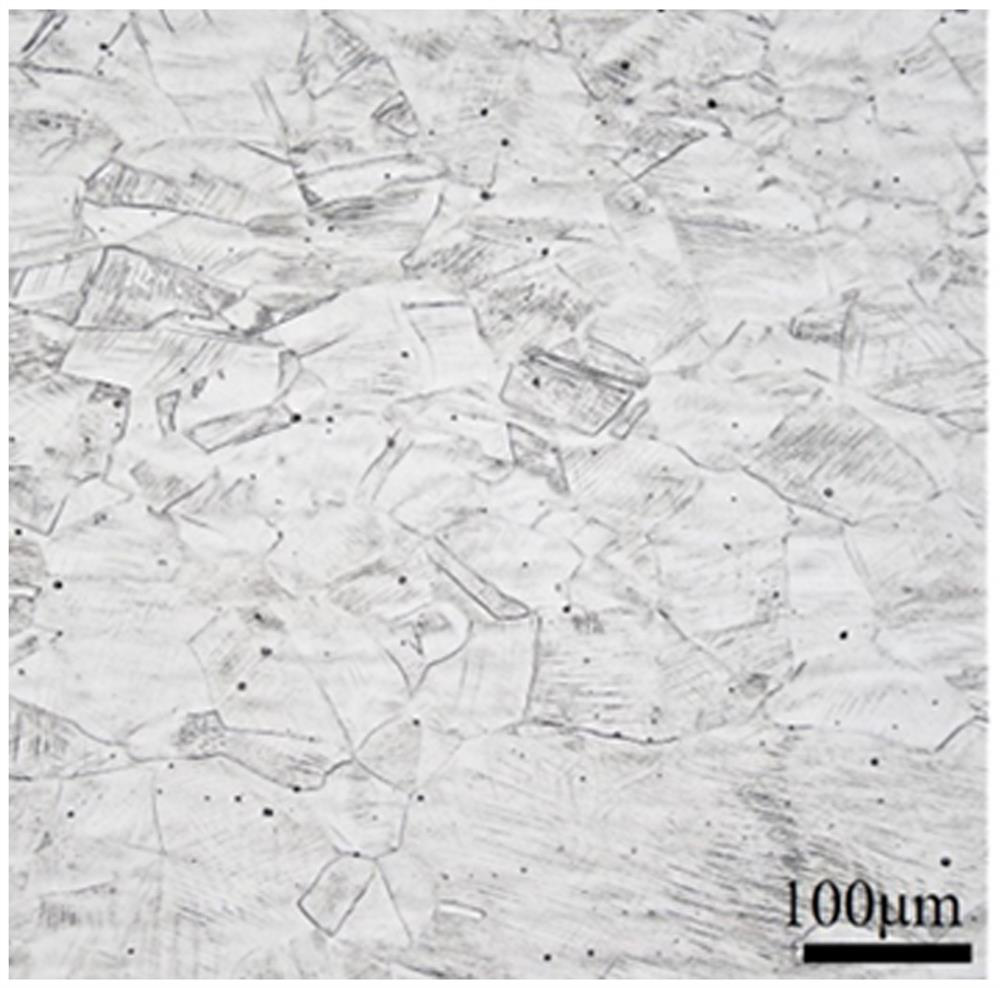

The invention discloses a method for preparing a novel austenitic stainless steel material with high strength and resistance to hydrogen embrittlement. The content (%) is C<0.08, Si<1.0, Mn 10~16, Ni 6~8, Cr 16~ 18.0, N 0.5~1, P<0.045, S<0.030, Mo 2.0~3.5 and smelting. After smelting, the material is forged at room temperature. After forging, the material is heat treated at 1050-1100°C, cooled in water, and taken out Immediately forge. After forging to a certain extent, heat treatment is carried out on the material at 850°C-950°C, and then heat preservation is carried out at 300°C-400°C, and the stainless steel material is forged twice in different directions. The preparation method of the material has good operability, and the result is accurate and reliable.

Description

technical field [0001] The invention relates to the technical field of anti-hydrogen embrittlement of stainless steel, in particular to a high-strength anti-hydrogen embrittlement process method for austenitic stainless steel materials. Background technique [0002] my country is a big hydrogen production and consumption country. In the process of hydrogen energy production and utilization, the high-pressure hydrogen system is the key. The high-pressure hydrogen system, that is, the system containing high-pressure hydrogen in the medium, is the core equipment for hydrogen energy storage and transportation, oil product quality upgrading and coal-to-clean energy. It has the characteristics of flammable and explosive medium, complex failure mechanism, and difficult manufacturing. [0003] Among them, the failure of equipment in high temperature and high pressure environment is an important factor that threatens its safe and stable operation. For example: On April 2, 2010, the ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C21D7/13C21D8/02C22C38/02C22C38/58C22C38/44

CPCC21D7/13C21D8/0205C21D8/0221C21D8/0247C22C38/001C22C38/02C22C38/44C22C38/58

Inventor 施巧英王雪菡邢百汇许峥傅王秦严豪杰吴芳月黄啟德周成双张林

Owner ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com