A washing machine and its control method

A control method and washing machine technology, applied in other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of the need to improve the washing effect, the shaking of the sealing structure, the single water flow, etc., to reduce washing water consumption, prevent overflow, and ensure drainage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

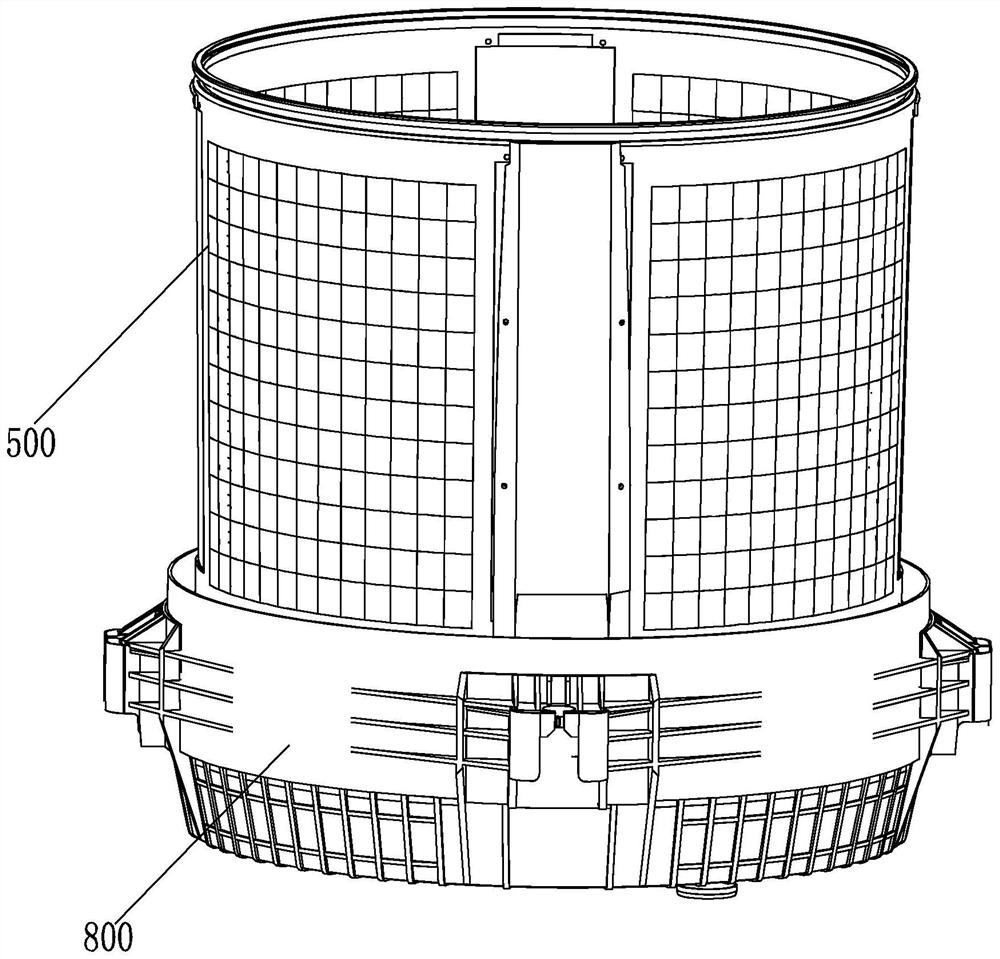

[0044] like Figure 1-Figure 6 As shown, the washing machine of this embodiment includes an inner tub 500 and a water collecting device 800. A drainage hole is provided at the bottom of the inner tub 500. During the washing process, there is no water between the inner tub 500 and the water collecting device 800. During the drainage process and the dehydration process, the inner tub 500 The water in the water enters the water collecting device 800 and is discharged therefrom.

[0045] The inner tub of the washing machine of the present embodiment is used as a water tub, so the inner tub adopts a "non-porous" design, and at the same time, the outer tub is cancelled and the water collecting device only collects the drainage of the inner tub for discharge. Therefore, the washing machine of this embodiment has the following technical effects:

[0046] 1. When the volume of the shell remains unchanged, the capacity of the inner tub can be increased to realize the expansion effect of...

Embodiment 2

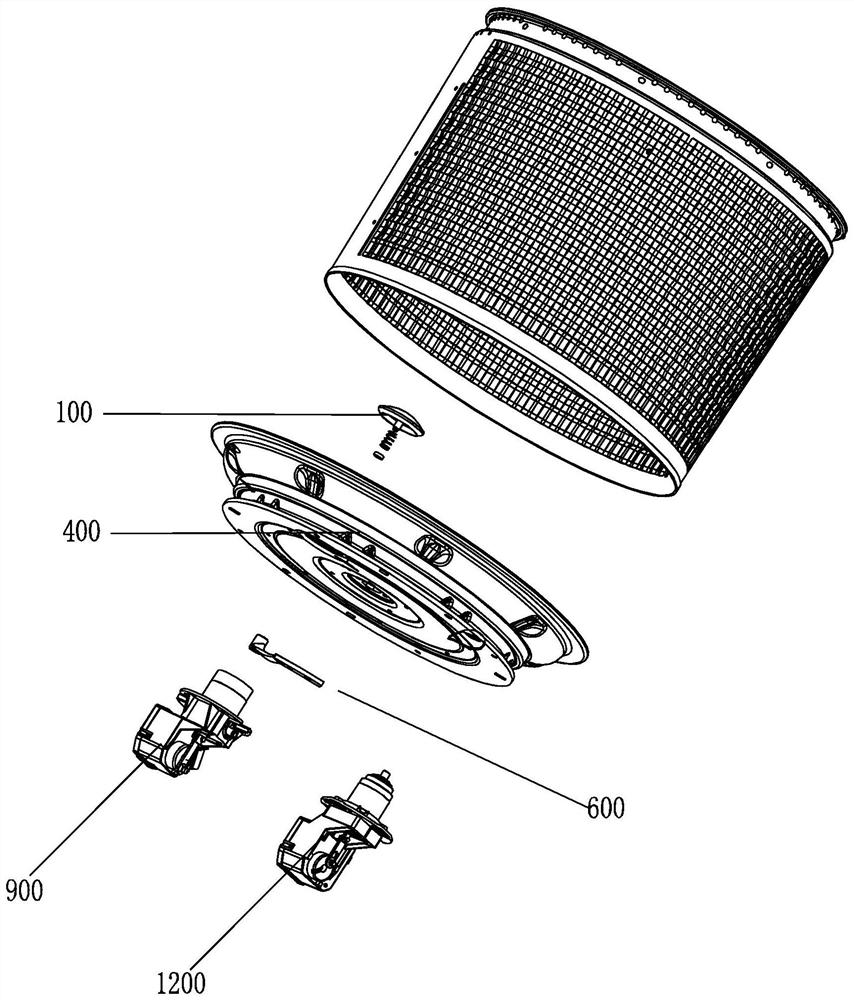

[0065] like Figure 7-Figure 9 As shown, in this embodiment, there is a drainage device for a washing machine. The washing machine includes an inner tub 500 with a drainage hole at the bottom of the inner tub 500. The drainage sealing device includes a sealing mechanism that can be sealed with the drainage hole. The sealing mechanism It includes a blocking member and a driving member 900. The blocking member includes a blocking member 100 and a supporting member 600. The supporting member 600 is fixedly installed at the bottom of the inner tub and extends to the drainage hole. The blocking member 100 can be relatively slidably installed on the supporting member. On 600:

[0066] When washing or rinsing, the blocking member 100 is sealed with the drainage hole, and the inner tub contains washing water; when draining, the blocking member 100 opens the drainage hole, and the washing water in the inner barrel is discharged from the drainage hole.

[0067] The drainage sealing dev...

Embodiment 3

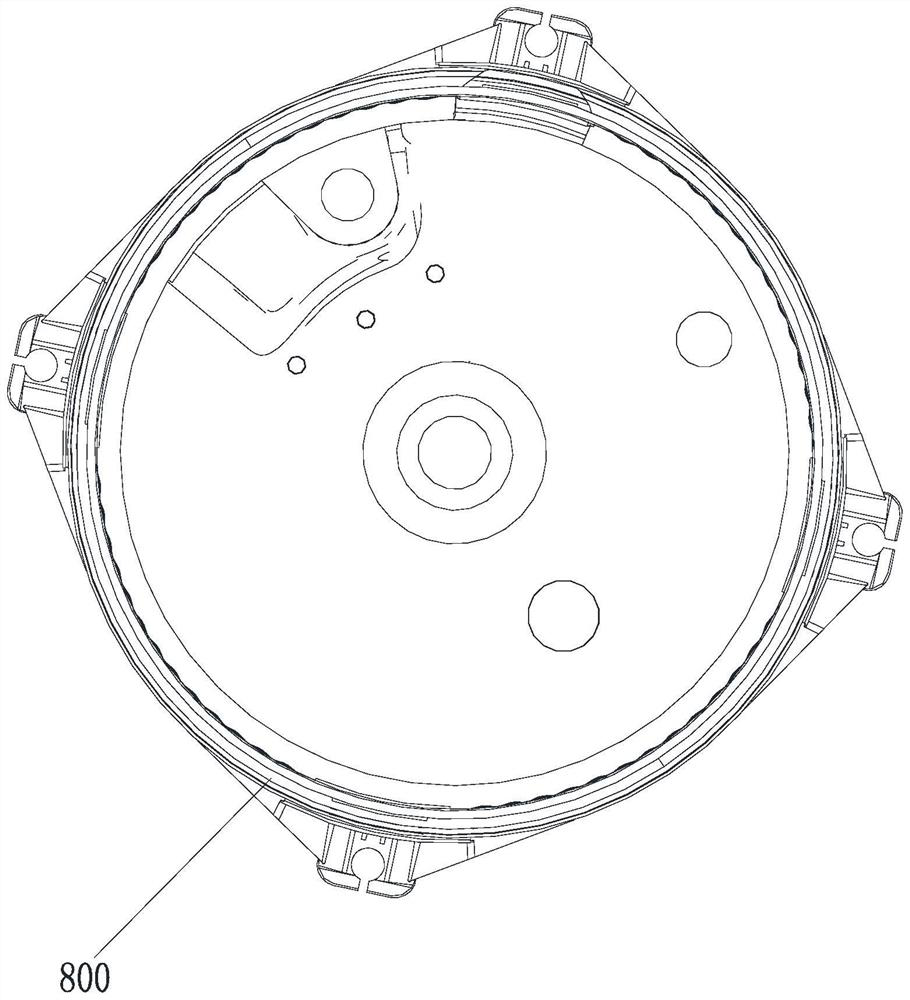

[0097] like Figure 10-Figure 13 As shown, the drainage device of this embodiment includes a sealing mechanism and a locking mechanism, the sealing mechanism includes a blocking member and a driving member, the blocking member is installed on the water outlet to keep it normally closed, and the driving member has a center along the center of the inner tub. The output end of the reciprocating motion in the direction parallel to the axis, the locking mechanism locks and locates the inner tub, the output end of the driving part reciprocates, and the blocking part is pushed out to open the drain hole / reset to close the drain hole; the The water collecting device is provided with a common mounting portion for mounting the driving components of the locking mechanism and the sealing mechanism at the same time.

[0098] In this embodiment, the driving components of the locking mechanism and the sealing mechanism are integrally mounted on the common mounting portion of the water collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com