Tool-type pile cap device for high-frequency vibration of steel pipe pile

A technology of high-frequency vibration and steel pipe piles, which is applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of difficult construction safety hazards, increase the use of on-site materials, increase labor input, etc., and reduce on-site construction The effect of time and material investment, ensuring the quality of pile sinking, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings and specific examples.

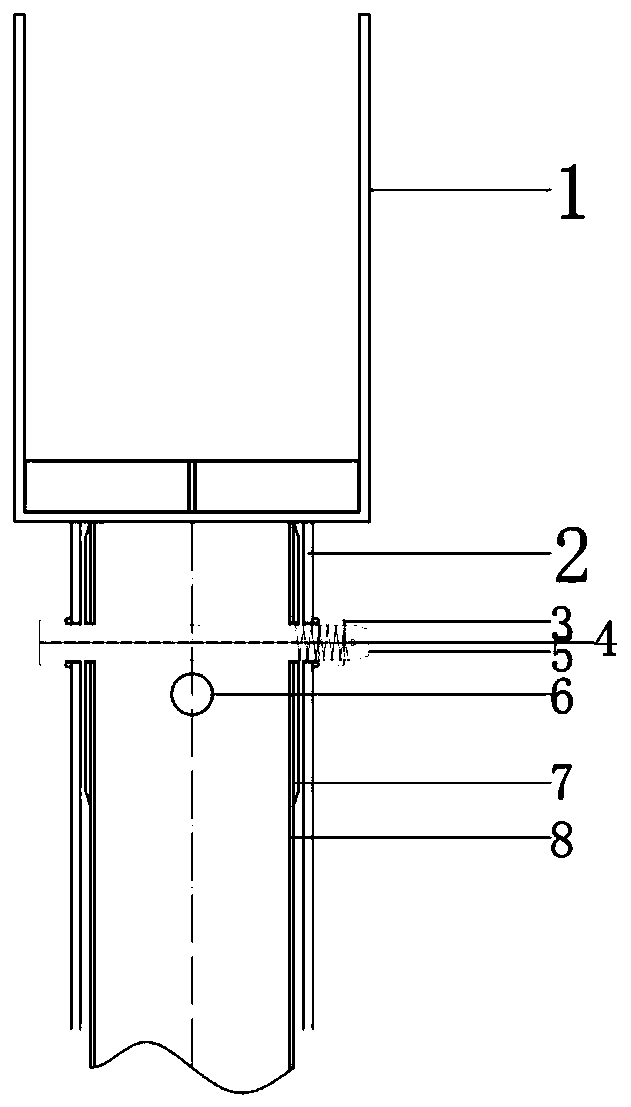

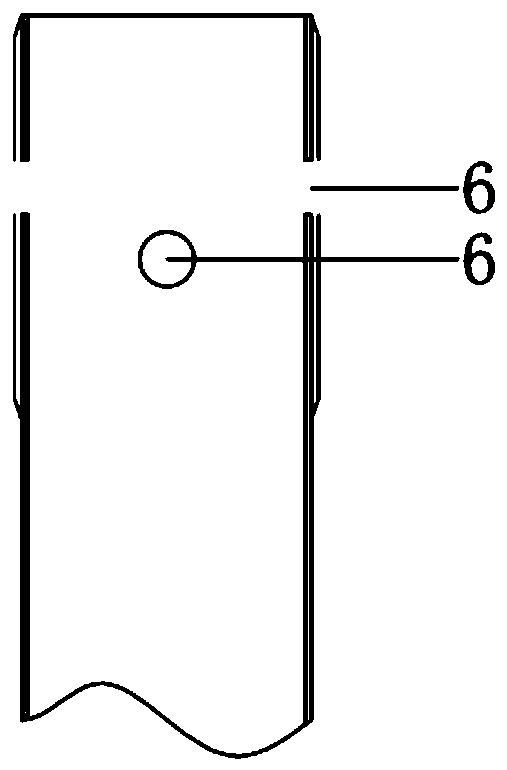

[0014] Such as figure 1 , Shown in 2, the steel pipe pile high-frequency vibration tool type pile cap device of the present invention includes a pile cap and a pin bolt 5 . The pile cap is composed of a pile cap upper part 1, a pile cap lower part 2 and the like. The lower part 2 of the pile cap and the reinforcing ring 7 of the steel pipe pile 8 are closely nested, and the lower part 2 of the pile cap is connected to the two orthogonal holes 6 reserved on the reinforcing ring 7 of the steel pipe pile 8 through the two cross pins 5 . Buckle together, pin bolt 5 heads are close to pile cap lower part 2, and pin bolt 5 afterbody has nut 3 to be tightly fixed on pile cap lower part 2 outer wall by screw thread, and is locked by pin hole 4. Ensure that the steel pipe pile 8 does not generate relative displacement between the pile ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com