Hydrogen heat exchange medium bimetal hydride work system

A technology of heat exchange medium and hydride, which is applied in steam engine devices, steam applications, machines/engines, etc., can solve problems affecting safe use, detonation, difficult storage and transportation of hydrogen, and achieve economic benefits of energy saving and emission reduction, creating The effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings. The protection scope of the present invention is not limited to the embodiments, and any changes made by those skilled in the art within the scope defined in the claims also belong to the protection scope of the present invention.

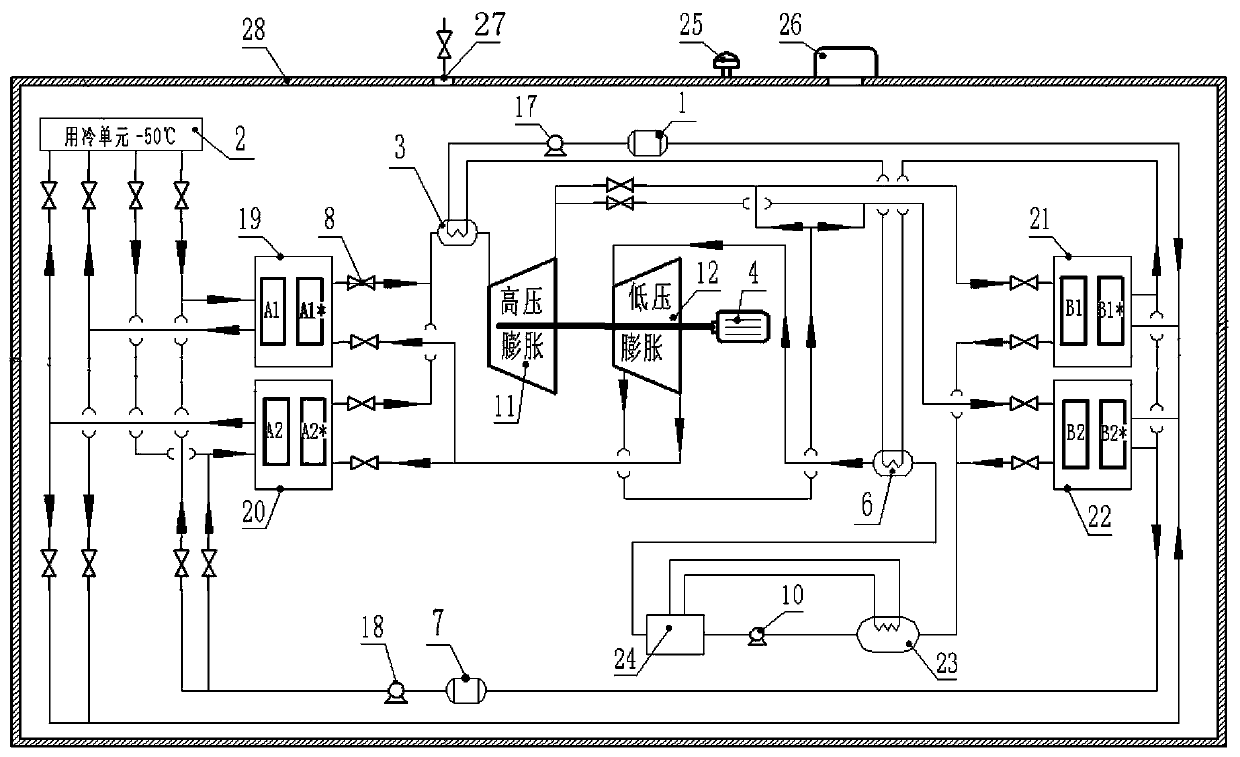

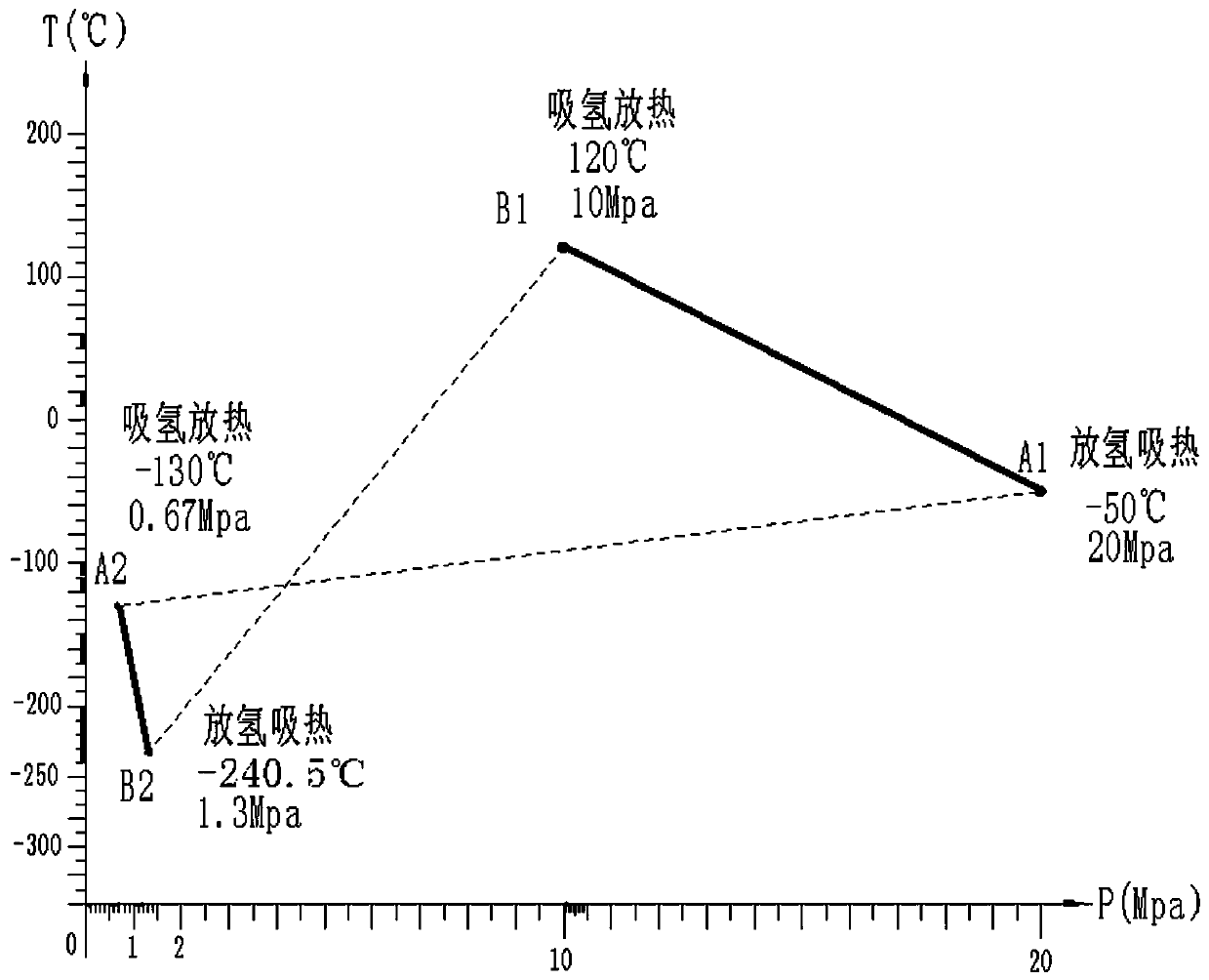

[0023] The invention provides a hydrogen heat exchange medium double metal hydride work system, such as figure 1 As shown, the work system includes a high-pressure hydrogen intermediate tank 1, a low-pressure hydrogen intermediate tank 7, A1 metal hydrogen storage reaction bed 19, A2 metal hydrogen storage reaction bed 20, B1 metal hydrogen storage reaction bed 21, B2 metal hydrogen storage reaction bed 22 , A hydrogen heat exchanger 3, B hydrogen heat exchanger 6, liquid hydrogen precooler 23, liquid hydrogen high pressure pump 10, cooling unit 2, refrigeration unit 24, high pressure expander 11, low pressure expander 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com