A kind of high stress leaf spring for mine dump truck

A mining dump truck, high stress technology, applied in springs, springs/shock absorbers, low internal friction springs, etc., can solve the problem of preventing misalignment and insufficient fixation, affecting the bending deformation of the lower reed, and reducing the elasticity of the leaf spring Adjustment force and other issues to avoid hard bumps, reduce contact area, and improve shock absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

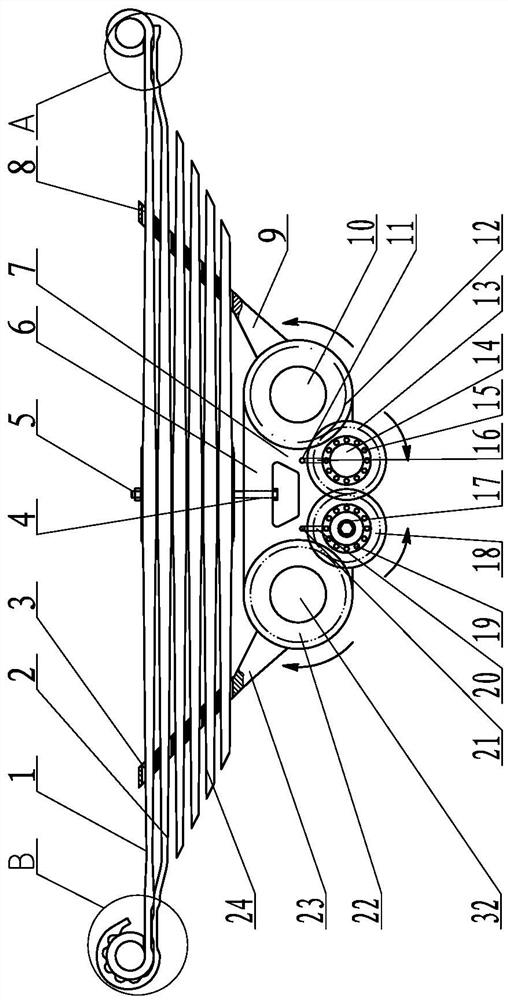

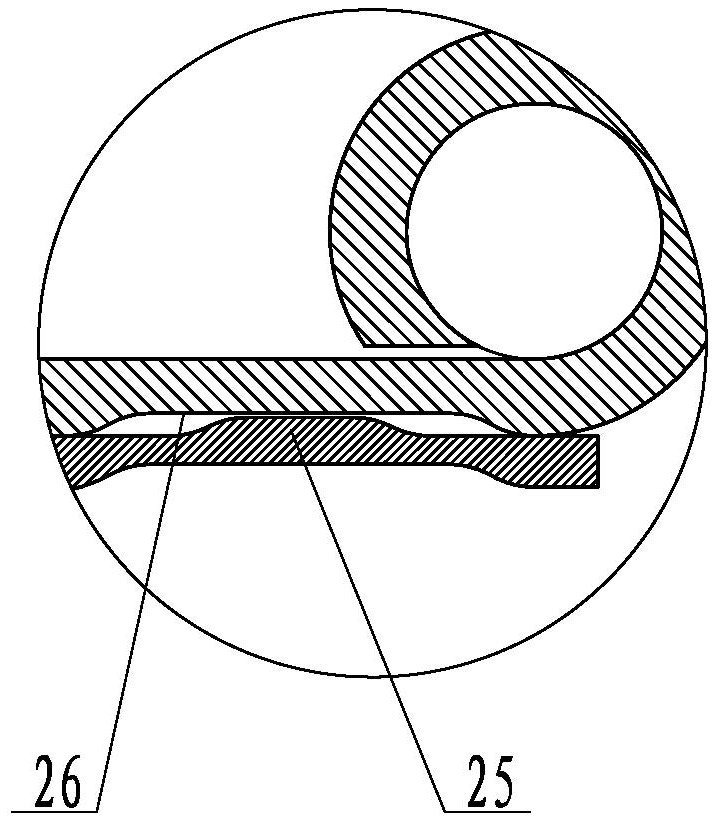

[0028] Such as figure 1 Shown, a kind of high-stress leaf spring for mining dump trucks includes a leaf spring body, and the leaf spring body includes a first upper reed, a second upper reed and several lower reeds, the first upper reed, The middle part of the second upper reed and each lower reed is connected and fixed by through fixing bolts. The left and right ends of the upper reed are provided with "O" shaped ears, and the left end of the lower reed is provided with "C" shaped ears. The "C"-shaped ear wraps the outer wall of the "O"-shaped ear of the upper reed, and the left and right hoops are respectively set on the left and right sides of the first upper reed, the second upper reed and several lower reeds. arm, set several left reed sockets on the upper part of the left hoop arm, and several right reed sockets on the upper part of the right hoop arm, the left ends of the first upper reed, the second upper reed and each lower reed Insert respectively into the left reed...

Embodiment 2

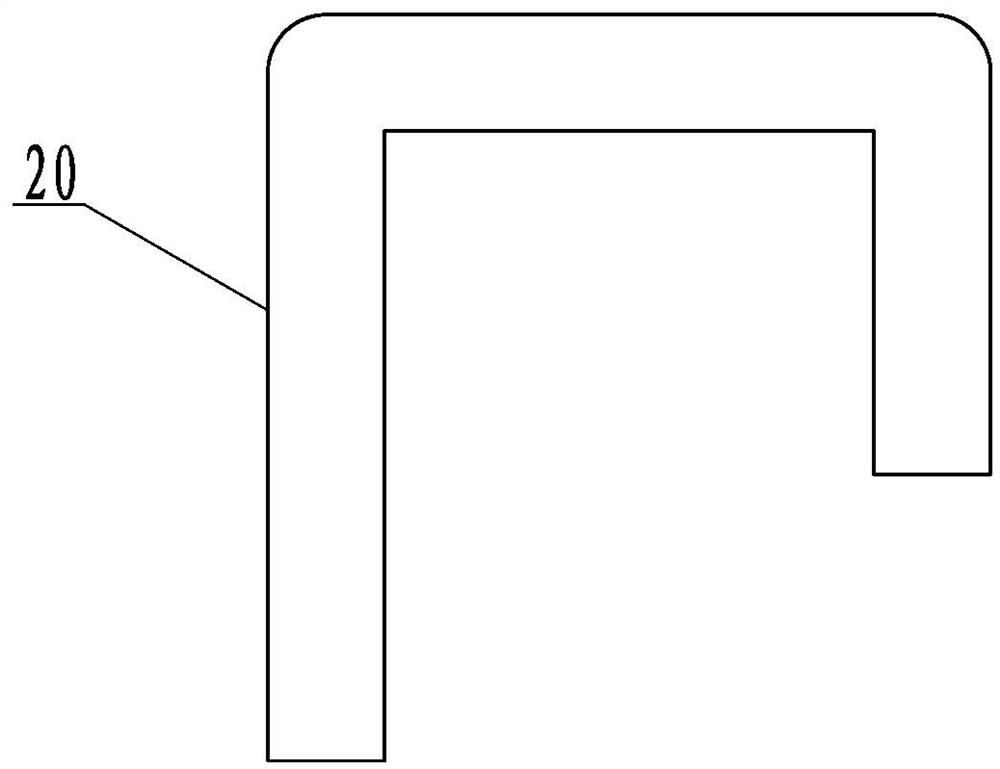

[0038] In this embodiment, a hexagonal cross-section rotary socket is provided on the central axis of the left driving gear, and an "L"-shaped hexagonal wrench can be inserted into the rotary socket. When in use, the rotation angle of the left driving gear can be adjusted by rotating the inner hexagonal wrench, and then the stress of the leaf spring can be adjusted.

[0039] The remaining structures and usage methods of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com