Transversely-installed longitudinal sealing plug

A sealing plugging and longitudinal technology, applied in the direction of pipes/pipe joints/fittings, mechanical equipment, pipe components, etc., can solve the problems of inconvenient installation of plugs, difficulty of leak test, and inability to place and operate tightening mechanism, etc., to avoid Leakage risk, good plugging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] This part is the embodiment of the present invention, which is used to explain and illustrate the technical solution of the present invention.

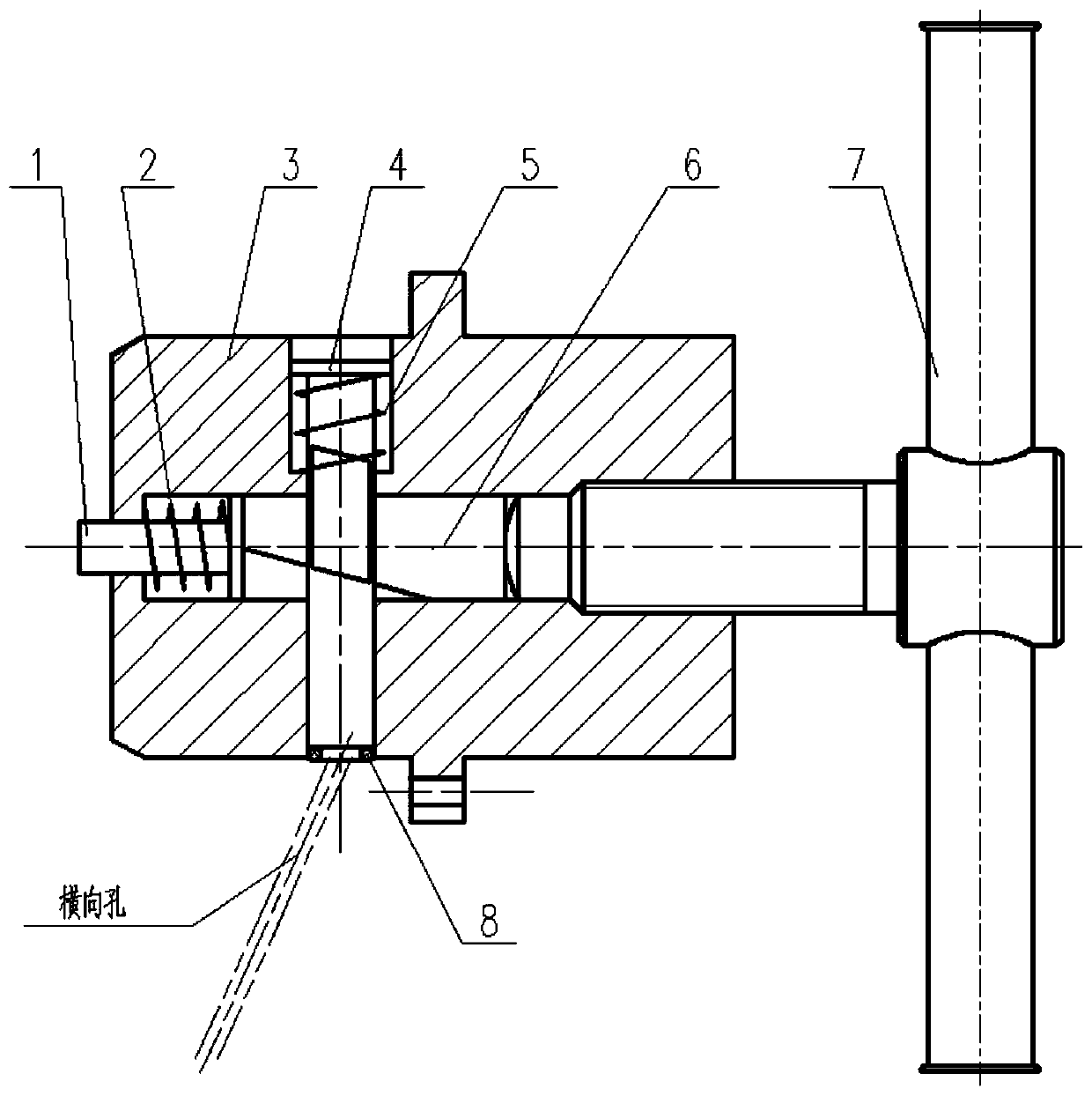

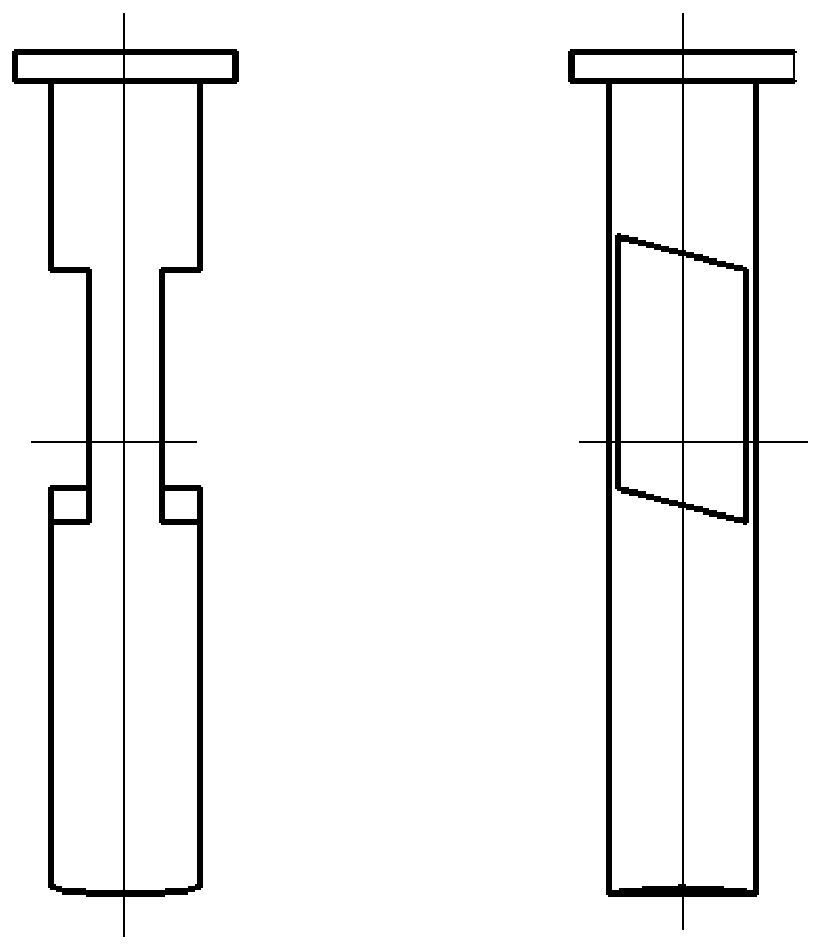

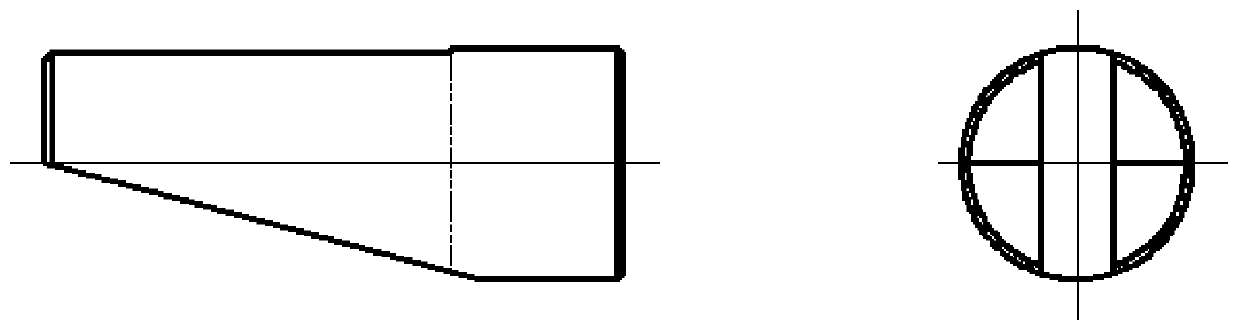

[0018] A horizontally installed vertical sealing plug, including a plug body 3, a push rod 4, an inclined block 6, a sealing structure, and a compression structure. There is a cross hole in the plug body 3, and the push rod 4 is arranged in the longitudinal hole of the cross hole , the end of the push rod 4 corresponding to the hole to be plugged is provided with a sealing structure, the inclined block 6 is arranged in the transverse hole of the intersecting hole, the outer end of the inclined block 6 is connected to a compression structure, and the compression structure is arranged outside the plug body 3; The lateral displacement of the inclined block 6 promotes the longitudinal displacement of the push rod 4 .

[0019] The pressing structure is a spinning screw 7, and the sealing structure is an O-ring 8; a push rod 1 is als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com