Electrodialysis electrode water plate water pressure test tool and detection method

A technology of hydrostatic testing and extreme water plate, applied in the field of electrodialysis, can solve the problems of disassembly, existence of risks, inability to repair and replace, etc., to achieve the effect of improving work efficiency, avoiding workload, and avoiding leakage risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] DRAWINGS Examples and further detailed description of the present invention, the following Examples are intended to explain the present invention and the present invention is not limited to the following embodiments.

[0024] Example.

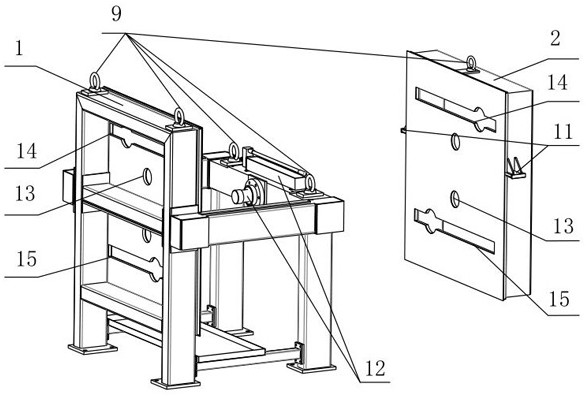

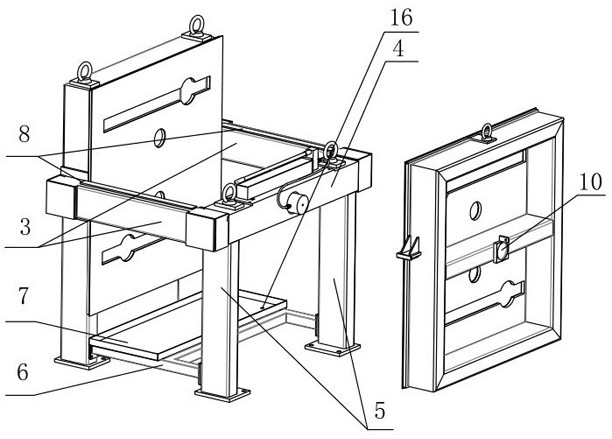

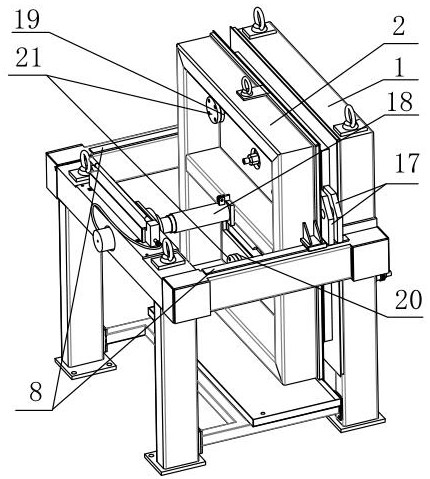

[0025] See Figure 1 to 4 , The present embodiment electrodialysis embodiment electrode plate water pressure test fixture includes a fixed-side bearing frame 1, frame 2 swimming pressing side, two load-bearing beams 3, the front end of cross member 4, two support legs 5 and the front end of the bottom cross beam 6, water tray 7, a slider 8, the bail 9, the pressing block floating center of the top side of the seat 10, traveling block 11 and the lug 12 of the hydraulic pressing mechanism.

[0026] like Figure 1 - Figure 2As shown, the fixed side pressure frame 1 in the present embodiment is provided with a support pin on both sides, and there are two hanging ring 9, and both sides are connected to one end of the two load beams 3; the front end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com