A visual pipe fitting blockage mechanism and its blockage method

A technology for pipe fittings and pipelines, applied in the field of blocking devices, can solve problems such as danger, block position deviation, energy waste, etc., and achieve the effects of saving processes and manpower, reducing the error rate of plugging, and improving the efficiency of plugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

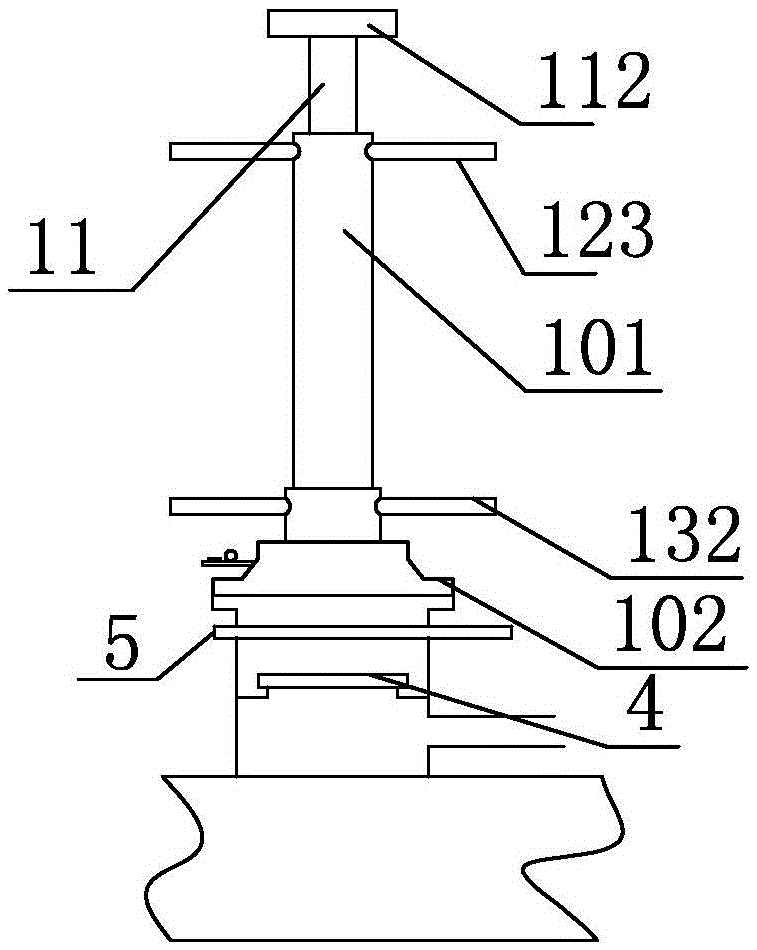

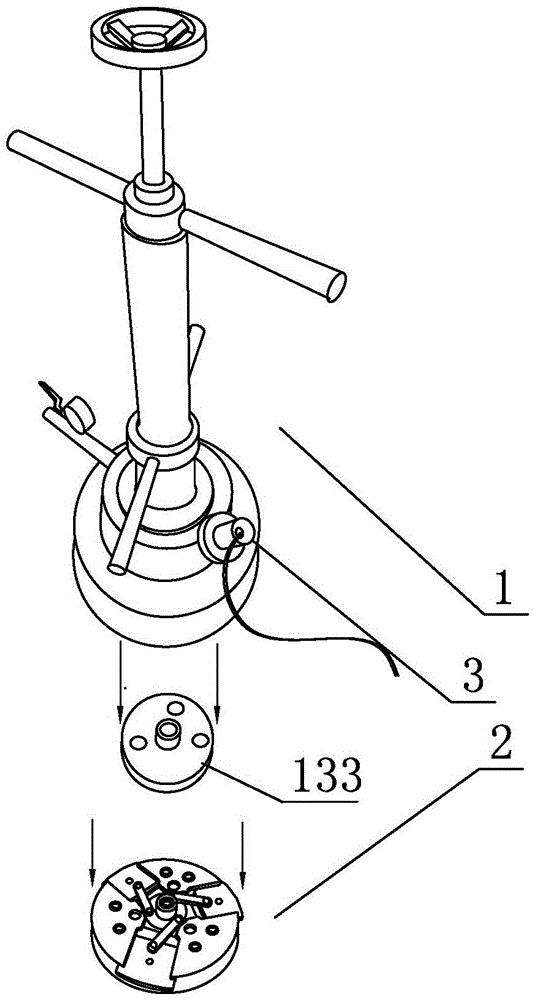

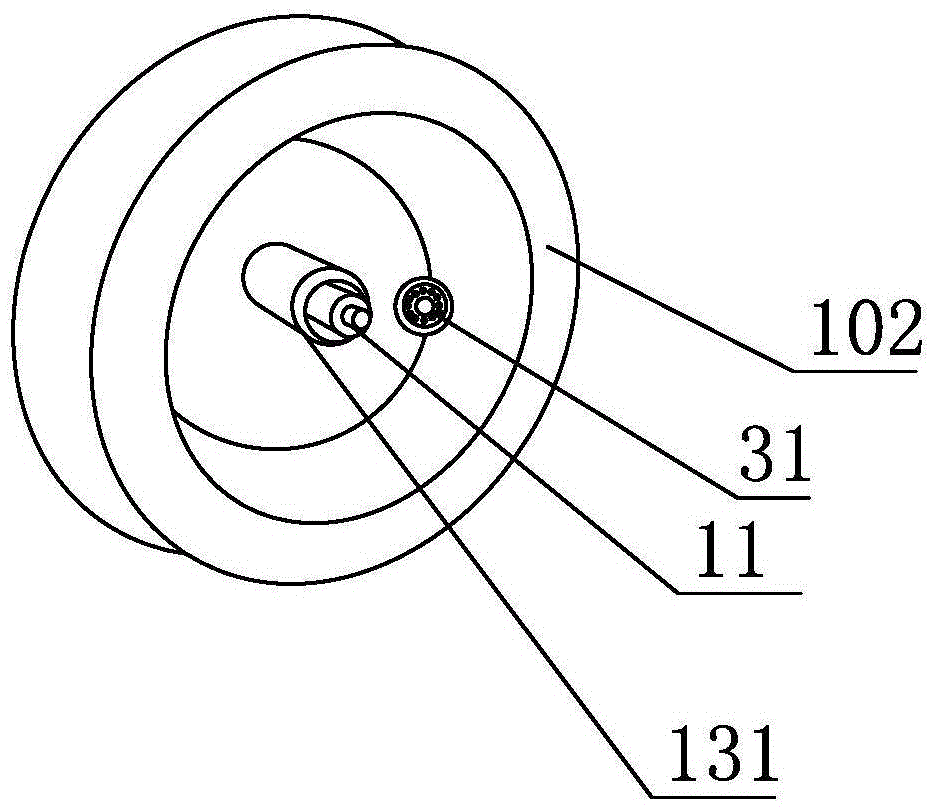

[0031] Such as Figure 1-5 As shown, the visualized pipe fitting plugging 2 mechanism of this embodiment includes a lower blocking device 1 and a plugging device 2, the lower blocking device 1 is used to place the plugging device 2 in the flange plugging seat 4 on the pipe fitting, and the lower blocking device 1 includes a housing 101 , the transmission rod 11 installed in the housing 101, the lifting device 12 for lifting the transmission rod 11, the separation connection device 13 for separating and connecting the plug 2, and the lower plug connecting box 102 fixedly connected with the housing 101, characterized in that: The lower block connecting box 102 is equipped with a monitoring device 3 for monitoring the movement of the lower blocking block 2 . Surveillance equipment 33, fixed seat 32 comprises camera fixture 321, connects the connection seat 322 of fixed camera fixture 321 and wire joint 323, and the side upper part of connecting box 102 has the through hole that i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com