Liquid ethane pipeline valve chamber discharging system and method thereof

A pipeline valve and venting system technology, which is applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc., can solve the unreported valve chamber design and research progress, and the construction of long-distance liquid ethane long-distance pipelines. Achieve the effects of reducing on-site installation work, good economy, and controlling engineering investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

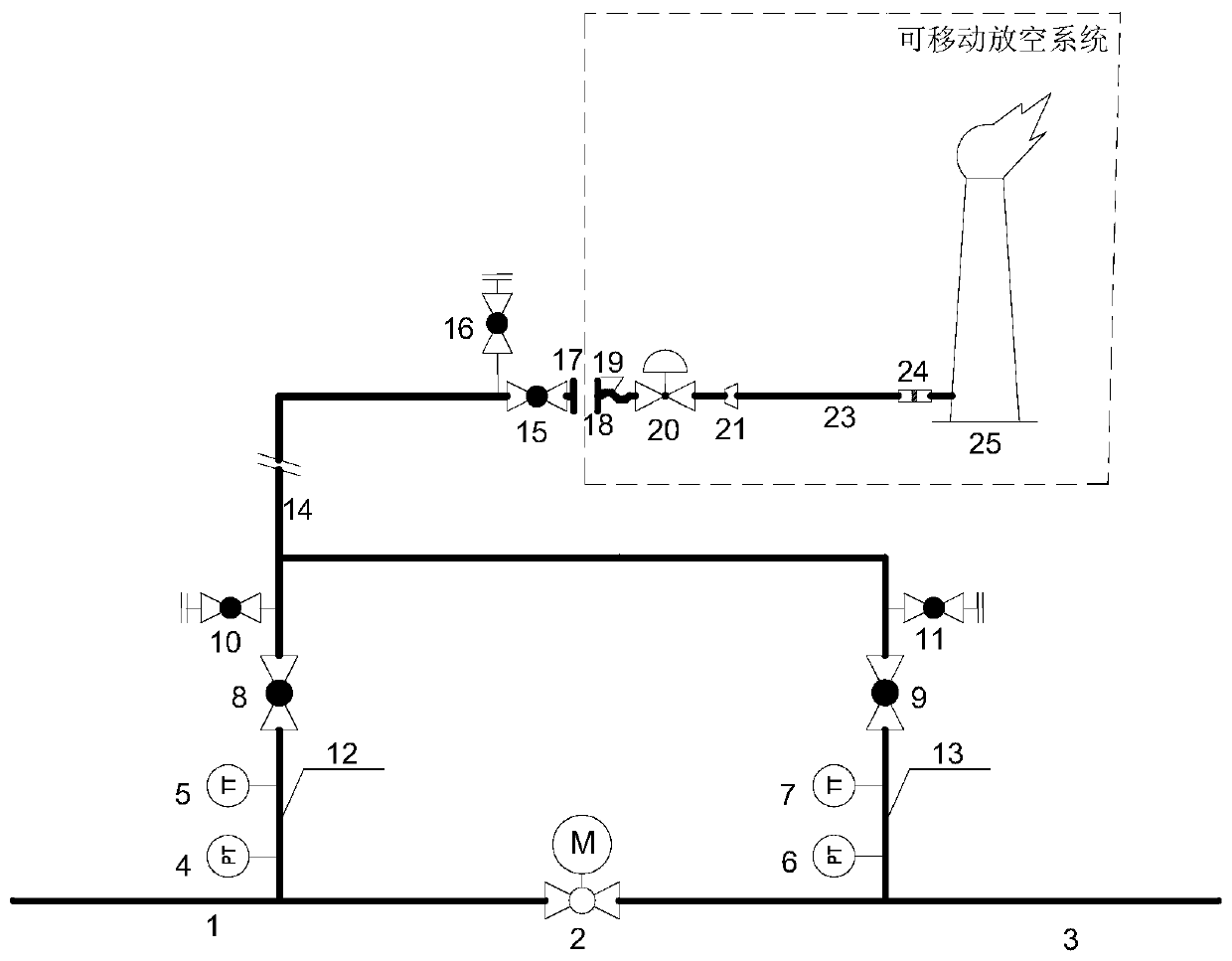

[0030] A liquid ethane pipeline valve room relief system, such as figure 1 As shown, it mainly includes: upstream buried main line 1, main line cut-off valve 2, downstream buried main line 3, pressure transmitter 4 / 6, temperature transmitter 5 / 7, bypass cut-off valve 8 / 9, bypass replacement Valve 10 / 11, upstream bypass pipe 12, downstream bypass pipe 13, bypass extension branch pipe 14, branch pipe cut-off valve 15, branch pipe replacement valve 16, branch pipe flange 17, butt flange 18, high-pressure hose 19, vent regulator Valve 20, big and small head 21, vent pipe 23, flame arrester 24, vent torch 25.

[0031] Among them, the upstream buried main line 1, the main line cut-off valve 2, and the downstream buried main line 3 form the valve chamber main line system, which is responsible for connecting the upstream and downstream pipelines to form a liquid ethane transmission channel; the main line shut-off valve 2 is responsible for connecting or cutting off the pipeline.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com