A liquid ethane pipeline valve chamber discharge system and method

A pipeline valve and venting system technology, applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve problems such as the lack of construction of long-distance liquid ethane pipelines, and the lack of reports on valve chamber design and research progress. Achieve the effect of reducing on-site installation work, good economy, and reducing the total investment of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

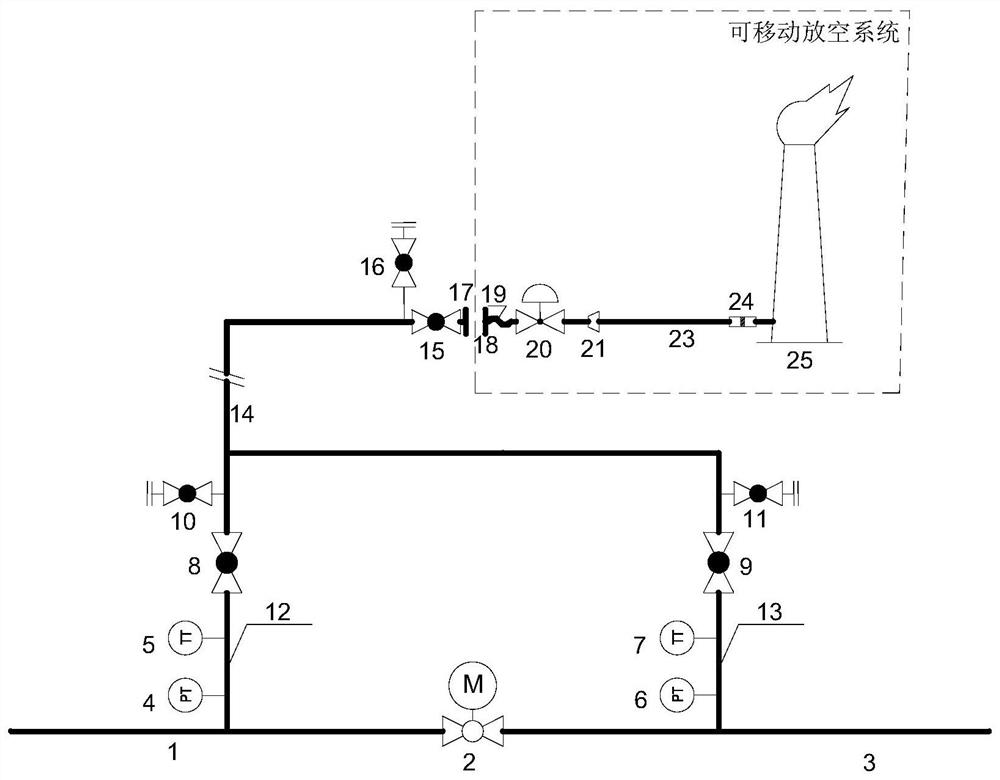

[0030] Liquid ethane pipe valve room discharge system, such as figure 1 As shown, mainly include: upstream buried trunk 1, trunk truncation valve 2, downstream buried trunk 3, pressure transmitter 4 / 6, temperature transmitter 5 / 7, bypass truncation valve 8 / 9, bypass replacement Valve 10 / 11, upstream bypass conduit 12, downstream bypass pipe 13, bypass extension branch 14, branch tube truncation valve 15, branching valve 16, branch tube flange 17, docking flange 18, high pressure hose 19, air conditioning The valve 20, the size head 21, the vent line 23, the fire detector 24, and take off the torch 25.

[0031] Among them, the upstream buried trunk 1, the trunk truncation valve 2, the downstream buried trunk 3 constitutes a valve chamber trunk system, which is responsible for connecting upstream pipes to form a liquid ethane delivery passage; the trunk truncation valve 2 is responsible for the pipe communication or truncation.

[0032] Specifically, the upstream buried trunk 1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com