System and method for monitoring fouling coefficient of plate heat exchange in real time

A plate heat exchanger and fouling coefficient technology, applied in heat exchange equipment, complex mathematical operations, cleaning heat transfer devices, etc., can solve problems such as equipment loss, difficult structure blockage, and inability to accurately obtain fouling coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

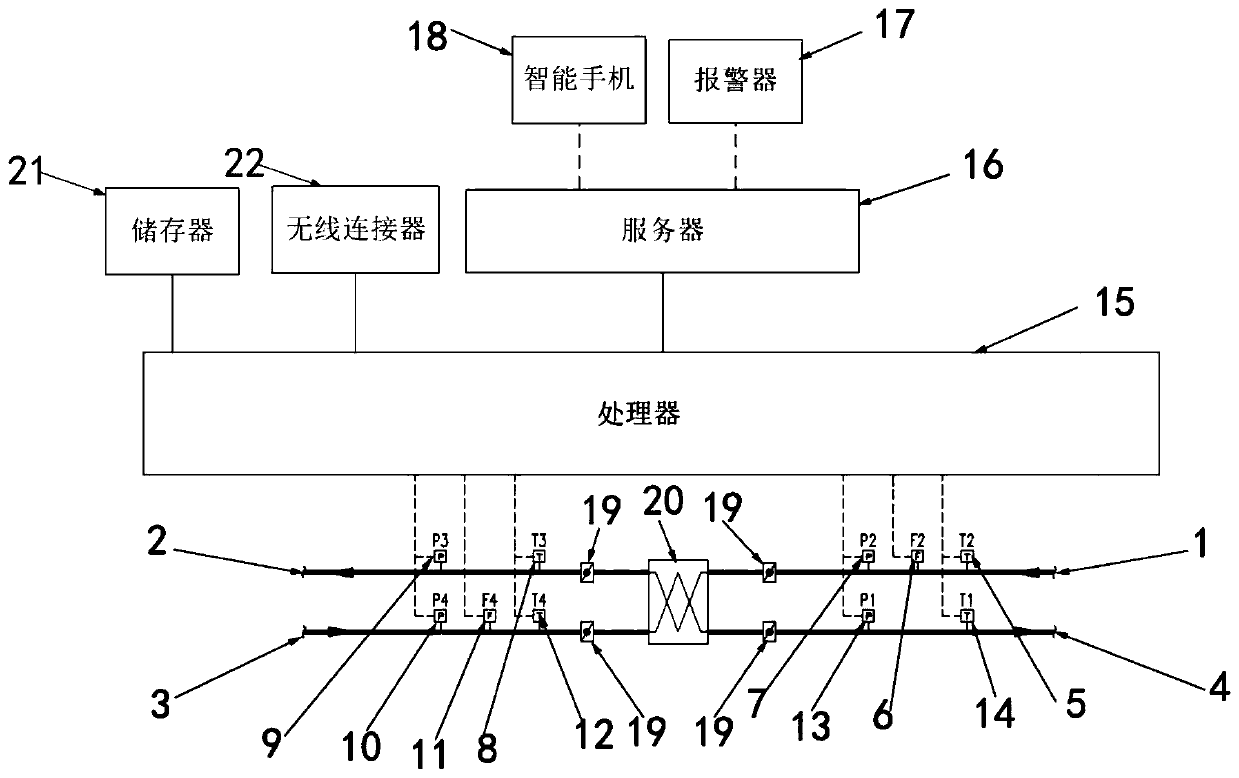

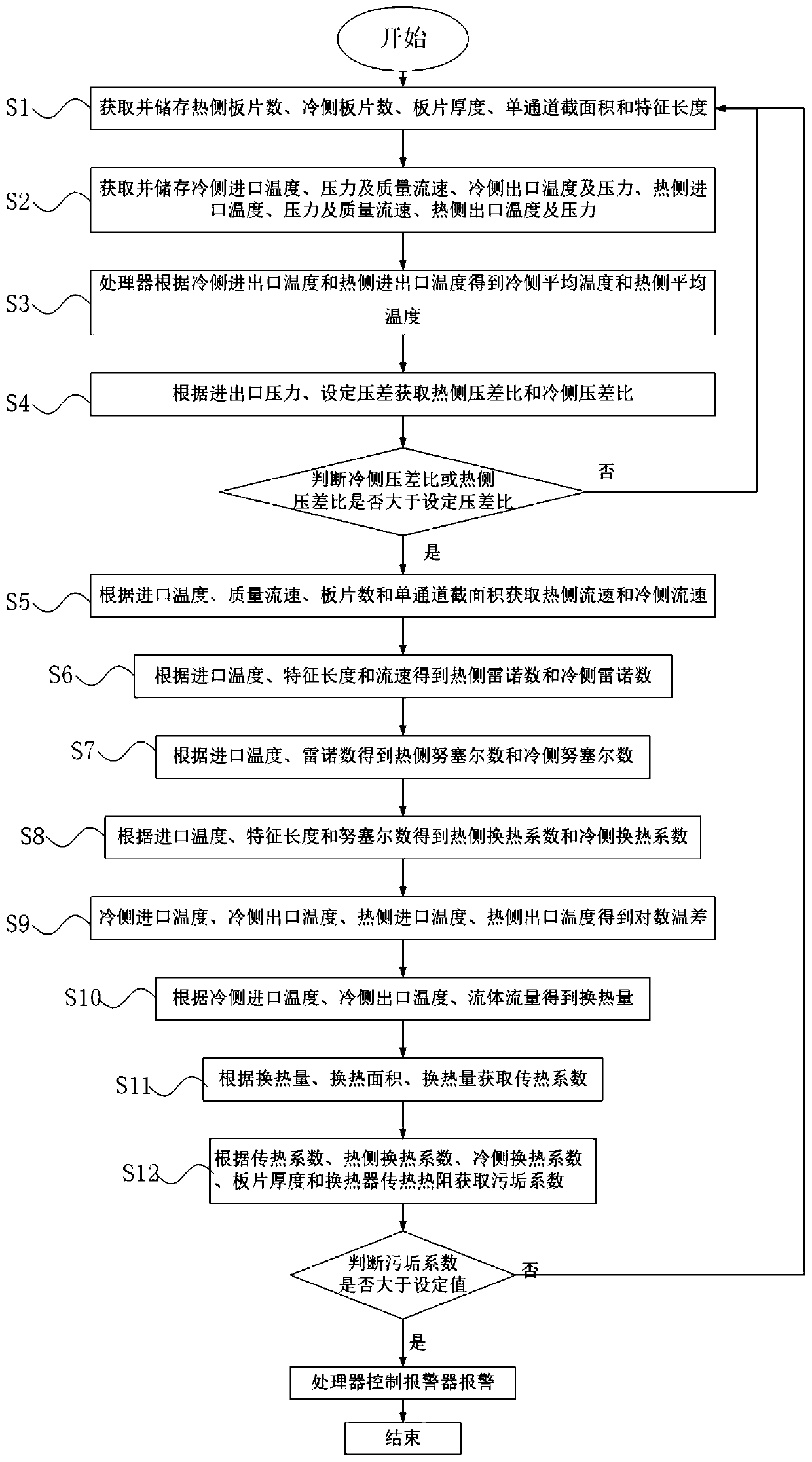

[0080] A system for monitoring the fouling coefficient of a plate heat exchanger in real time. The plate heat exchanger 20 includes a cold side inlet 1, a cold side outlet 2, a hot side inlet 3 and a hot side outlet 4, a cold side inlet 1, a cold side outlet 2, a hot side The pipes of the side inlet 3 and the hot side outlet 4 are provided with disc valves 19, the disc valves 19 are electric butterfly valves, the disc valves 19 are connected with the processor 15, and the system also includes a first sensor assembly, a second sensor assembly, and a third sensor Component, fourth sensor component, processor 15, server 16, alarm 17, smartphone and storage 21, first sensor component, second sensor component, third sensor component, fourth sensor component, server 16 and storage 21 are respectively connected with the processor, and the output end of the server 16 is connected with the input end of the alarm device 17 and the smart phone 18.

[0081] Wherein, the first sensor assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com