Multifunctional atmospheric sampling system and method

An atmospheric sampling and sampling system technology, applied in cleaning methods and appliances, chemical instruments and methods, sampling, etc., can solve the problems of low gas monitoring values, affecting data quality, poor air tightness, etc., and achieve good chemical stability, The effect of ensuring accuracy and ensuring airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

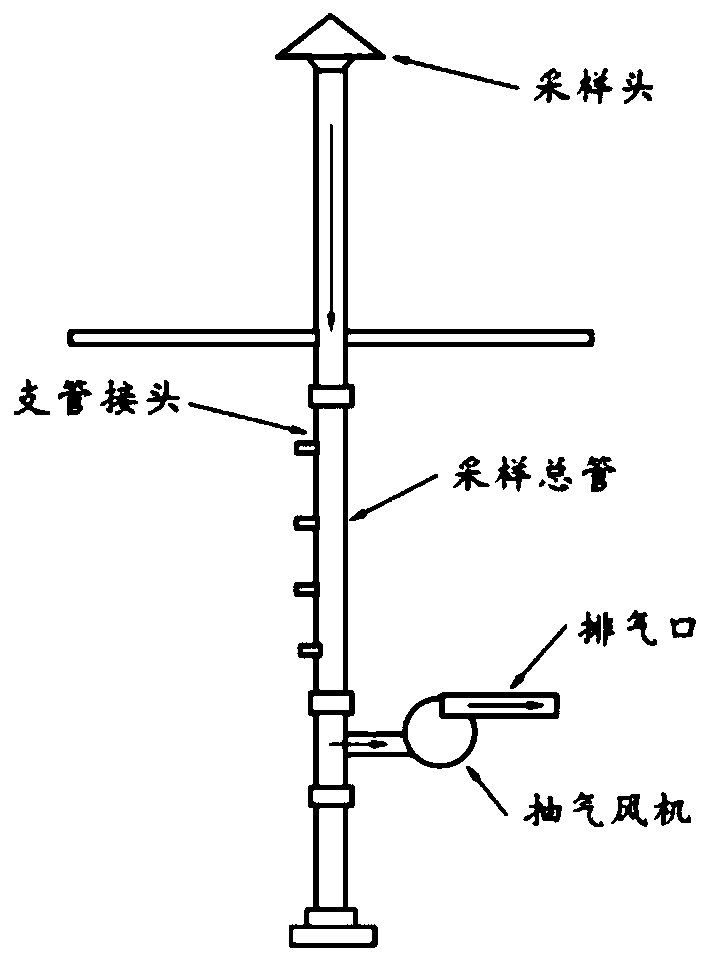

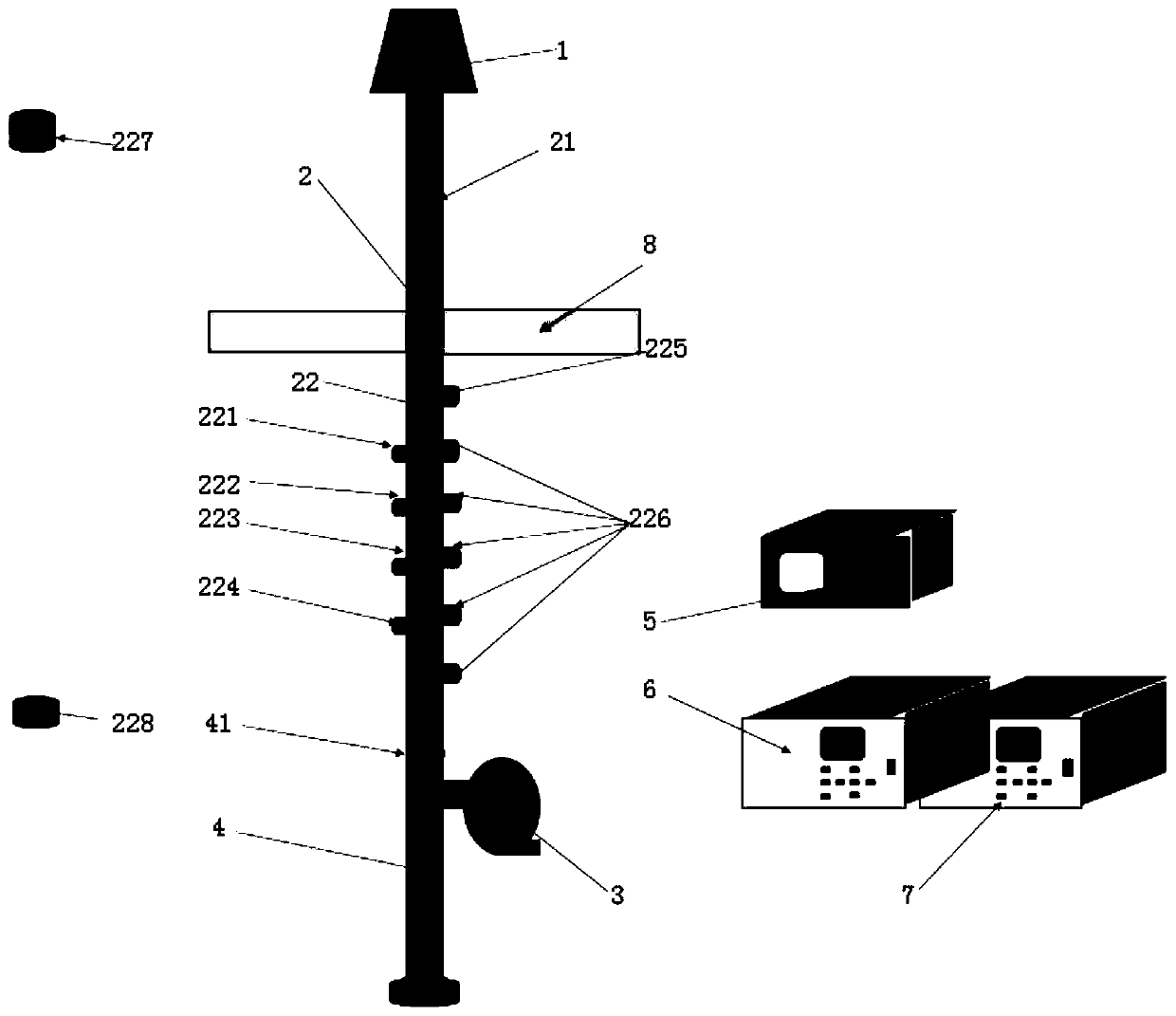

[0084] The multifunctional air sampling system in this embodiment includes a sampling head 1 , a sampling pipe 2 , an exhaust fan 3 , a telescopic support frame 4 connected to an indoor pipe 22 , a sampling system controller 5 and an analyzer 6 .

[0085] The sampling pipe 2 has an inner sampling layer 2-1 and an outer protective layer 2-4, the inner sampling layer 2-1 is a borosilicate glass tube, and the outer protective layer 2-4 is a PVC pipe or a stainless steel pipe; the sampling pipe 2 is divided into Outdoor pipe 21 is long 1.8m, is positioned at outdoor roof 8 top and indoor pipe 22 is long 1.2m, is positioned at indoor; The space between the inner sampling layer 2-1 of outdoor pipe 21 and the outer protective layer 2-4 is equipped with a plurality of O-type Circle, indoor pipe 22 is provided with heating insulation device, and this heating insulation device comprises the heating layer 2-2 and insulation layer 2-3 between the inner sampling layer 2-1 of indoor pipe 22 ...

Embodiment 2

[0091] Different from Embodiment 1, the multifunctional atmospheric sampling system of this embodiment also has the following airtight inspection structure: an airtight inspection seal and a vacuum pump, and the airtight inspection seal includes a plug 227 on the sampling tube, a lower The plug 228 and the interface seal are used to block other interfaces and ports except for the airtightness inspection interface I during the airtightness inspection; the microprocessing control unit also includes an airtightness inspection unit, which is connected with the pressure sensor 221 It is connected with the solenoid valve I, and the gas in the sampling pipe 2 is extracted from the interface I225 through the solenoid valve I during the air tightness inspection; the solenoid valve I in this embodiment adopts a two-way valve.

Embodiment 3

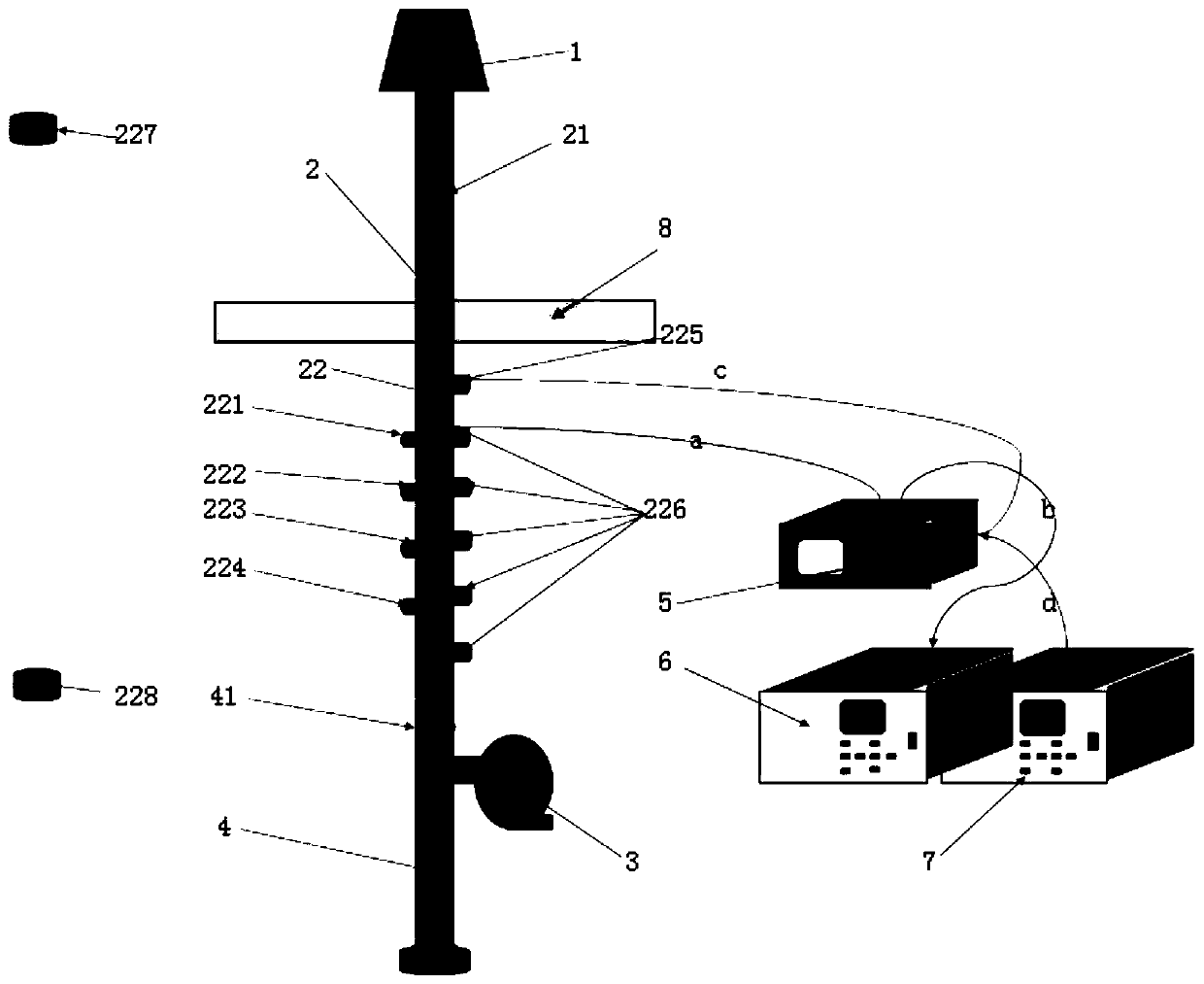

[0093] Different from Embodiment 1, the multifunctional atmospheric sampling system of this embodiment also has the following system calibration structure:

[0094] A calibrator 7 providing a standard gas,

[0095] The system calibration interface set on the indoor tube 22—interface I 225,

[0096] The solenoid valve I corresponding to the interface I 225 and the solenoid valve II corresponding to one of the sampling interfaces 226 are arranged in the sampling system controller 5,

[0097] The microprocessing control unit includes a system calibration unit, and the system calibration unit is respectively connected with the pressure sensor 221, the flow rate sensor 224, the exhaust fan 3, the solenoid valve I, the solenoid valve II and the analyzer 6; when performing system calibration, the standard The gas enters the sampling pipe 2 from the standard instrument 7 through the solenoid valve I through the interface I 225, and then is extracted from the sampling interface 226 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com