Food quality analysis and detection device

A detection device, food quality technology, applied in the direction of measurement device, analysis of materials, material analysis by optical means, etc., can solve the problem of no portable equipment, etc., to achieve accurate image detection, improve accuracy, and improve the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

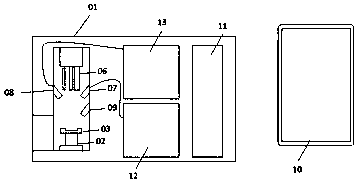

[0032] This embodiment introduces the device and its functions of the present invention.

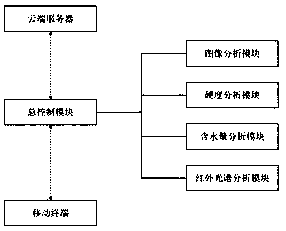

[0033] A food quality analysis and detection device, comprising a general control module 11, an image analysis module, a hardness analysis module, a water content analysis module, an infrared spectrum analysis module and a mobile terminal 10;

[0034] The total control module 11 is electrically connected to the image analysis module, the hardness analysis module, the water content analysis module, and the infrared spectrum analysis module, and the total control module 11 is wirelessly connected to the mobile terminal 10; the mobile terminal 10 is used to take overall image shots of the food to be analyzed, and Send the captured image to the general control module 11 to identify the type of food to be analyzed;

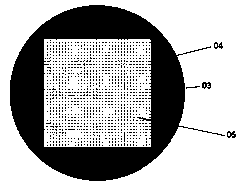

[0035] The image analysis module is used to collect images of the food samples to be analyzed, and analyze the collected images to obtain the first freshness of the food to be an...

Embodiment 2

[0048] This embodiment introduces the analysis method of the present invention. The method of use is as follows:

[0049] First, use the mobile terminal to take the overall image of the food to be analyzed, and then upload it to the cloud server. The cloud server analyzes the image to obtain the type of food to be analyzed, such as cake, cucumber, tomato, apple, etc.; Species, such as Red Fuji apple, Marshal Huang apple, Aksu pear, etc.;

[0050] Then cut the food to be analyzed and put it into the detection station of the sample tray for image detection to obtain the first freshness; then conduct infrared spectrum detection to obtain the second freshness, the second hardness coefficient, and the second water content. Then perform a hardness test to obtain a first hardness coefficient; perform a water content test after the hardness test to obtain a first water content;

[0051] After the total control module 11 obtains the first freshness, the first hardness coefficient, th...

Embodiment 3

[0055] The device of the present invention can also comprehensively test the hardness coefficient and water content to obtain the water loss-hardness coefficient curve;

[0056] When judging the grade of the hardness coefficient, the hardness coefficient under a fixed water content is first selected for judgment, so as to ensure that the hardness is carried out under the same water content, thereby improving the detection accuracy of the hardness grade.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com