Multi-path temperature control heating current detection system

A heating current and detection system technology, applied in the direction of using digital measurement technology for measurement, etc., can solve problems such as increasing the cost of current transformers, high rated power of DC power supply, and unfavorable troubleshooting, and is conducive to standardizing cable routing. , Easy assembly and maintenance, the effect of reducing the number of cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

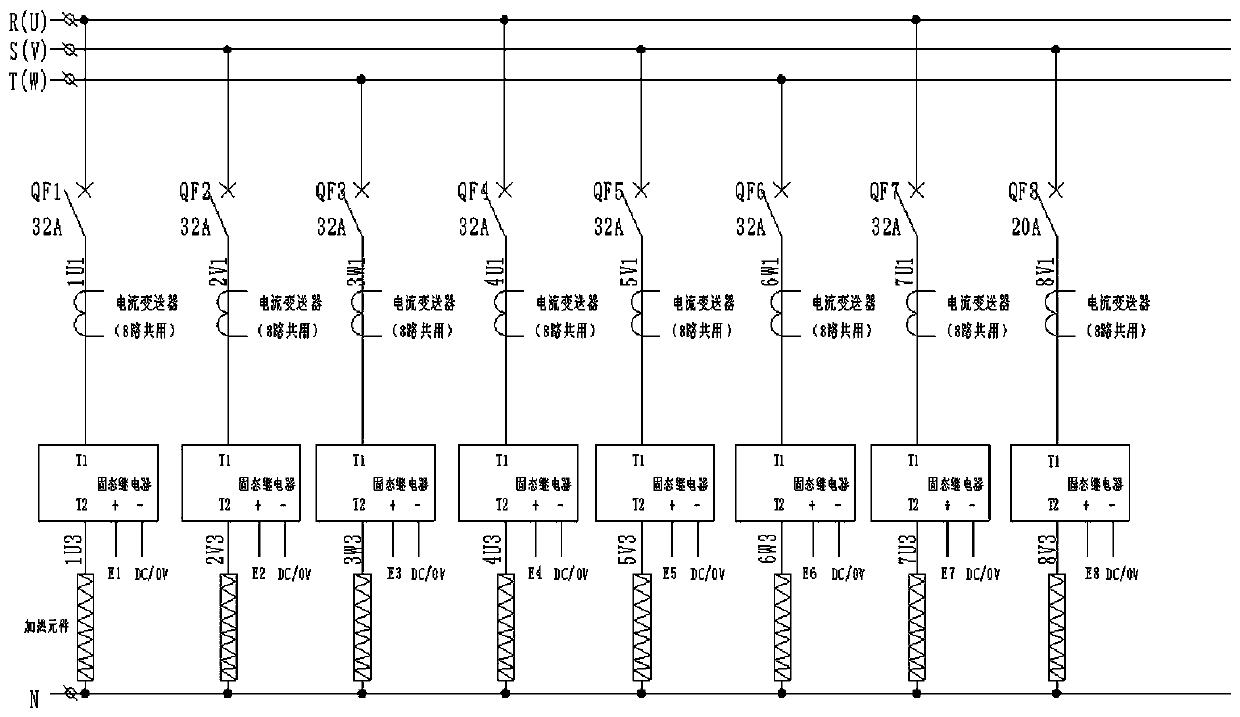

[0018] see figure 1 As shown, it is a schematic structural diagram of a preferred embodiment of the present invention. The present invention is a multi-channel temperature-controlled heating current detection system, mainly through the distribution of temperature-controlled heating zones, and each 8-zone heating main circuit passes through a current transmitter , through the linear relationship conversion of the PLC system, the measured current value is obtained. If the 8 heating zones are continuously heating, then the actual measurement of the current transmitter is the sum of the 8 heating zones, and further conversion is required to obtain The actual current of a single circuit.

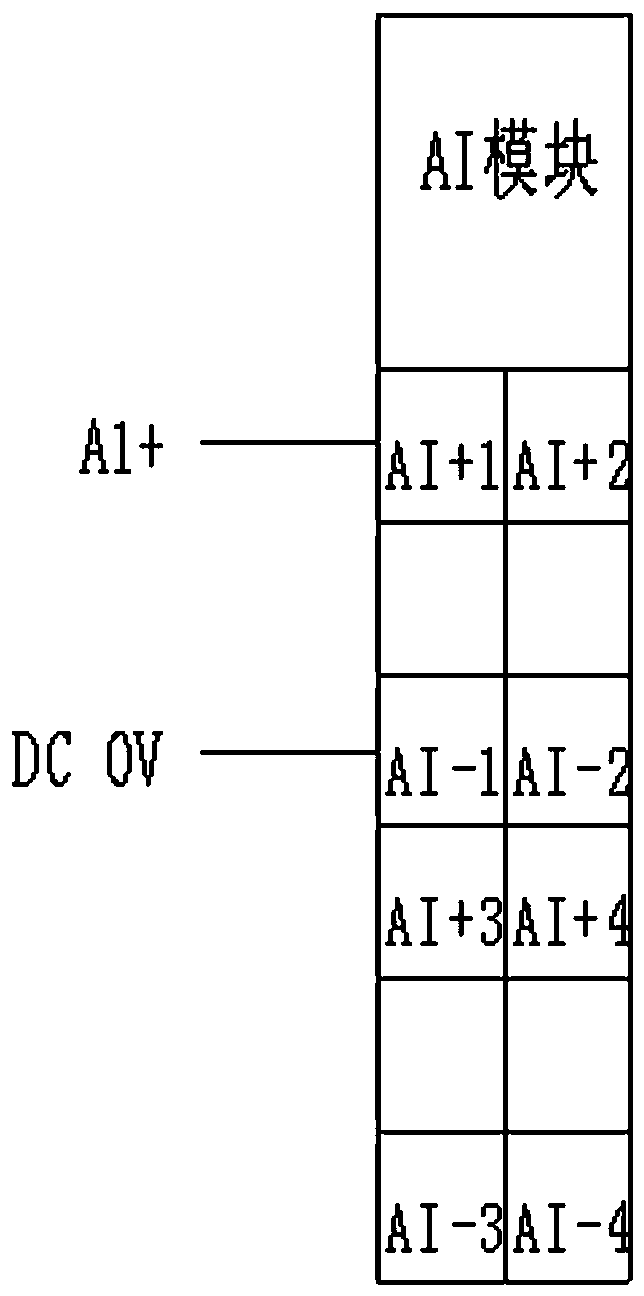

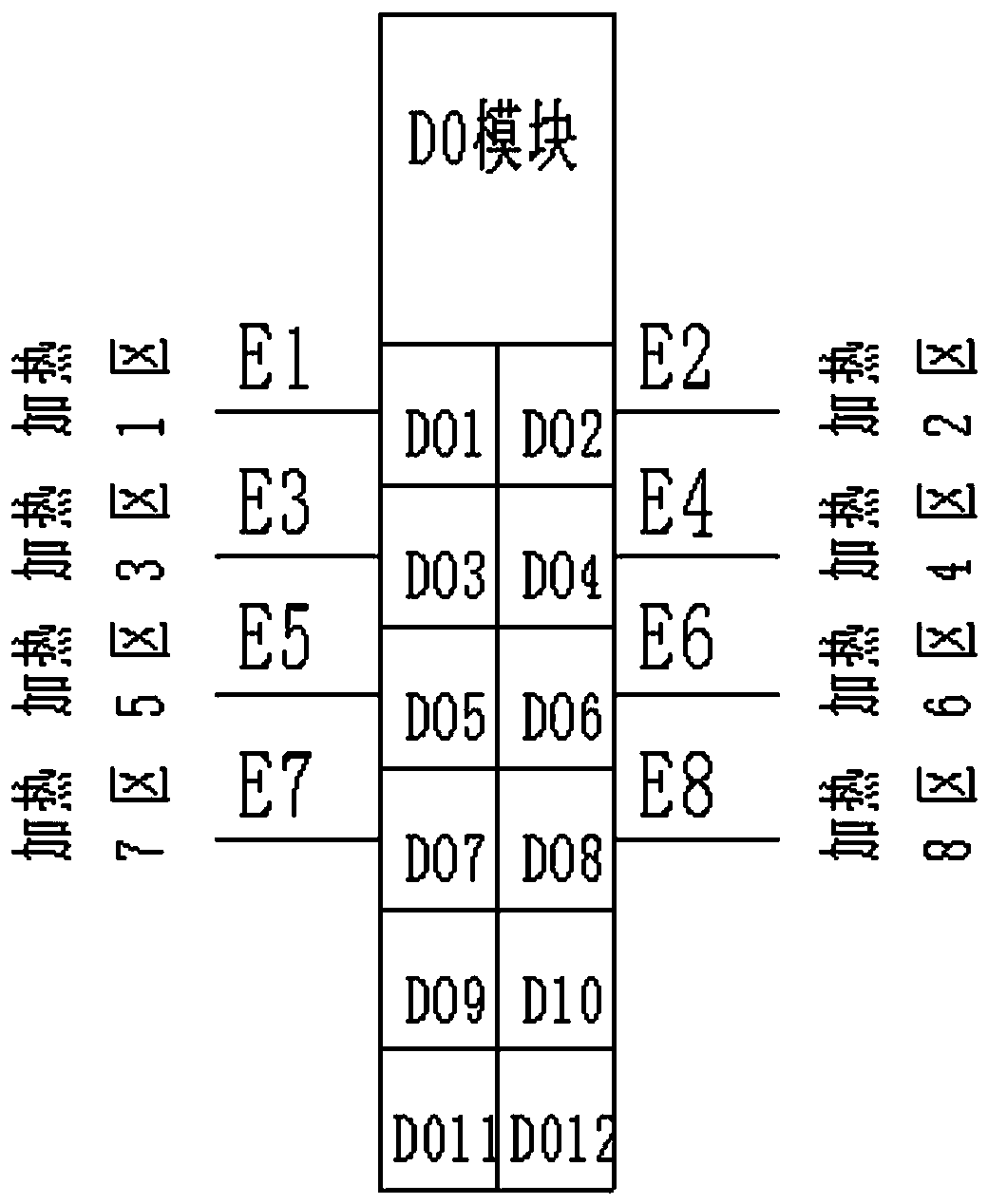

[0019] Such as figure 2 , image 3 As shown, the PLC system includes a PLC analog input module and a PLC digital output module, that is, the current transmitter converts the measured current value into a DC analog signal and transmits it to the PLC analog input module, which is converted by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com