Exhaust gas incineration recovery furnace

A technology for recovering furnace and exhaust gas, which is applied in the field of boilers, which can solve problems such as the decline of atmospheric environment quality, national economic losses, and human health hazards, and achieve the effects of improving trouble-free running time, eliminating fault maintenance, and reducing the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

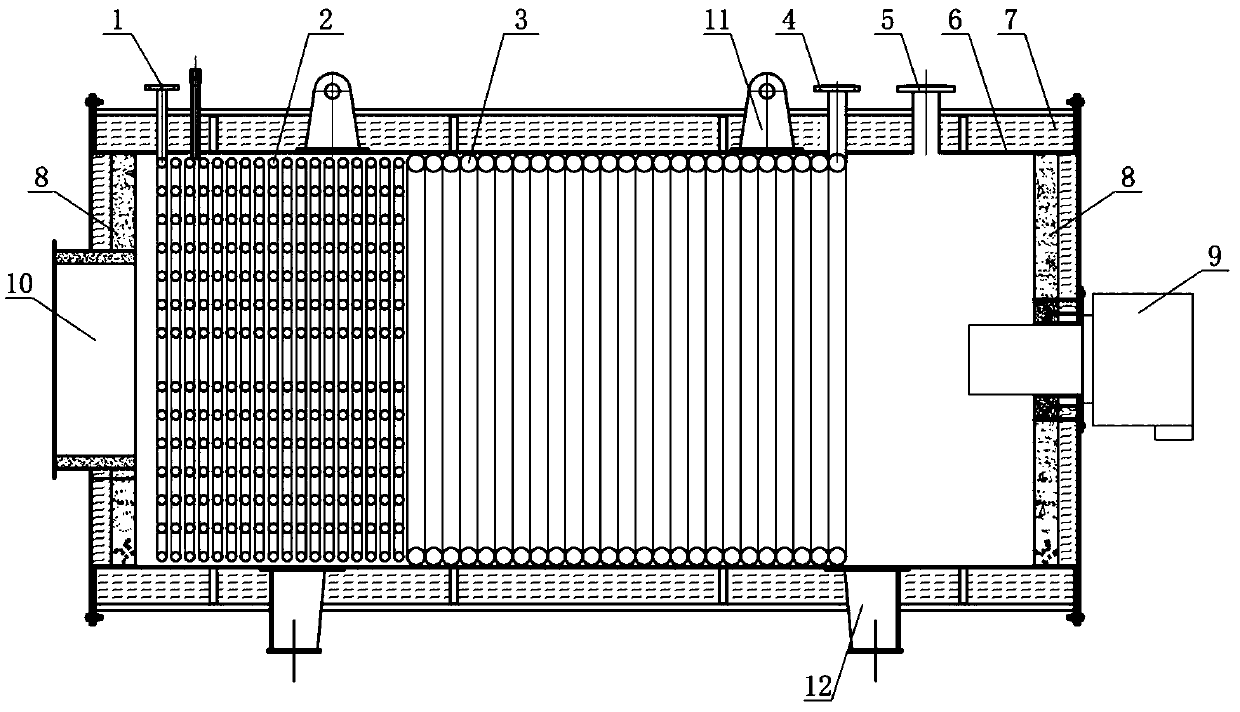

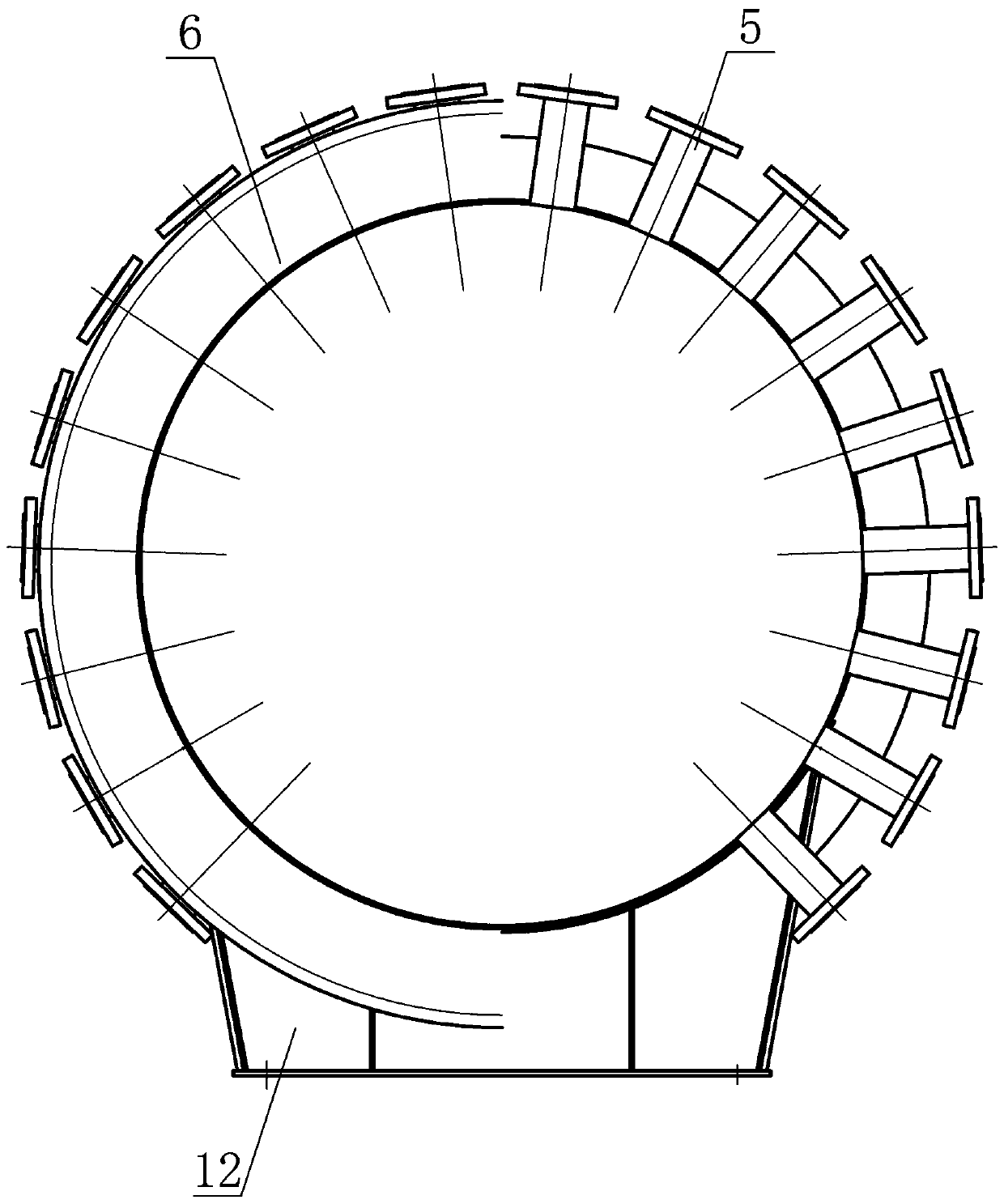

[0021] according to figure 1 , 2 As shown: this embodiment provides a waste gas incineration recovery furnace, including a waste gas nozzle 5, a boiler shell 6, an insulating material layer 7, a burner 9, a convection heating surface furnace tube 2 inside the boiler shell 6, and a radiation heating surface Furnace tube 3;

[0022] The boiler shell 6 is a circular cylinder with a horizontal installation structure. The boiler shell 6 is rolled from a steel plate made of 20# (GB713) "steel plate for boiler and pressure vessel". The bottom of the boiler shell 6 is installed There is a support 12 welded and fixed to it. Two sets of supports 12 are arranged near the front end and the rear end to support the boiler shell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com