A method for preparing mandelic acid from trichloroisocyanuric acid chlorostyrene

A technology of trichloroisocyanuric acid chlorostyrene and trichloroisocyanuric acid, which is applied in the direction of carboxylate preparation, carbon-based compound preparation, chemical instruments and methods, etc., can solve the problem of high price, outdated methods and environmental pollution Large and other problems, to achieve the effect of less waste discharge and short production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

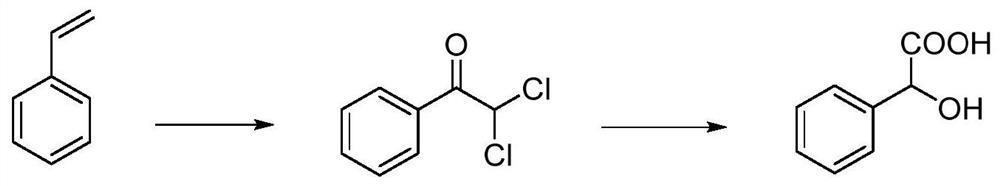

[0033] S1. Add styrene, ethylene glycol dimethyl ether and water into a three-necked flask, add trichloroisocyanuric acid, heat up to complete the reaction, cool the reaction solution to room temperature, filter, and recover the filtered white solid for use. The filtrate was extracted with dichloromethane, the organic layer was collected, and the solvent was evaporated to dryness under reduced pressure to obtain 2,2-dichloroacetophenone.

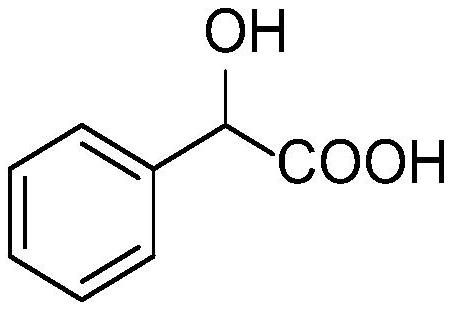

[0034] S2. Hydrolyze 2,2-dichloroacetophenone in a sodium hydroxide solution under stirring, adjust the pH to 2-3 with hydrochloric acid, and cool to precipitate the product mandelic acid.

Embodiment 2

[0036] S1. Dissolve 1.04g (10mmol) of styrene in a mixed solution of ethylene glycol dimethyl ether and water, slowly add 1.3eq of trichloroisocyanuric acid in an ice bath, heat up to 70°C, and continue to stir the reaction to the end of the reaction. The reaction solution was cooled to room temperature, filtered, added to the filtrate, extracted with dichloromethane, filtered, and spin-dried to obtain 1.31 g of 2,2-dichloroacetophenone, and the white solid cyanuric acid was recovered by filtration, with a recovery rate of 95%.

[0037] S2, take 10ml of sodium hydroxide solution with a mass fraction of 10%, slowly add the crude product in the step (2) dropwise, the temperature is controlled at 50°C, keep it warm for one hour, then adjust the pH to 1-2 with hydrochloric acid, add 0.1g of activated carbon fades, heat preservation for one hour, and 1.06g of crystals precipitate out.

Embodiment 3

[0039] S1. Dissolve 1.04g (10mmol) of styrene in a mixed solution of ethylene glycol dimethyl ether and water, slowly add 1.5eq of trichloroisocyanuric acid in an ice bath, heat up to 70°C, and continue to stir the reaction to the end of the reaction. The reaction solution was cooled to room temperature, filtered, added to the filtrate, extracted with dichloromethane, filtered, and spin-dried to obtain 1.59 g of 2,2-dichloroacetophenone, and the white solid cyanuric acid was recovered by filtration, with a recovery rate of 95%.

[0040] S2, take 10ml of sodium hydroxide solution with a mass fraction of 10%, slowly add the crude product in the step (1) dropwise, the temperature is controlled at 50°C, keep it warm for one hour, then adjust the pH to 1-2 with hydrochloric acid, add 0.1g of activated carbon fades, heat preservation for one hour, and 1.27g of crystals precipitate out.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com