Intelligent control method for chip mounter motion system based on binary spline scale function

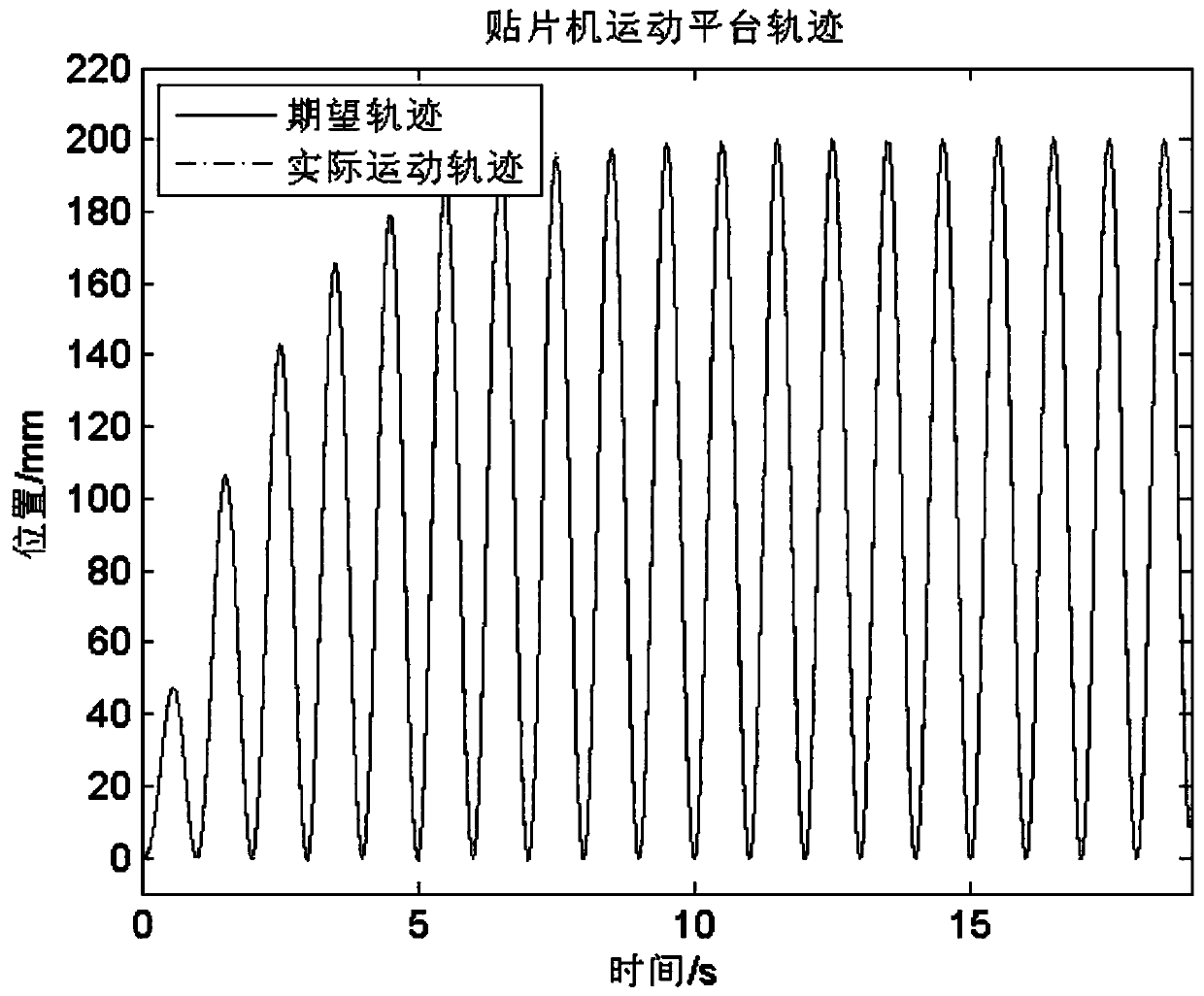

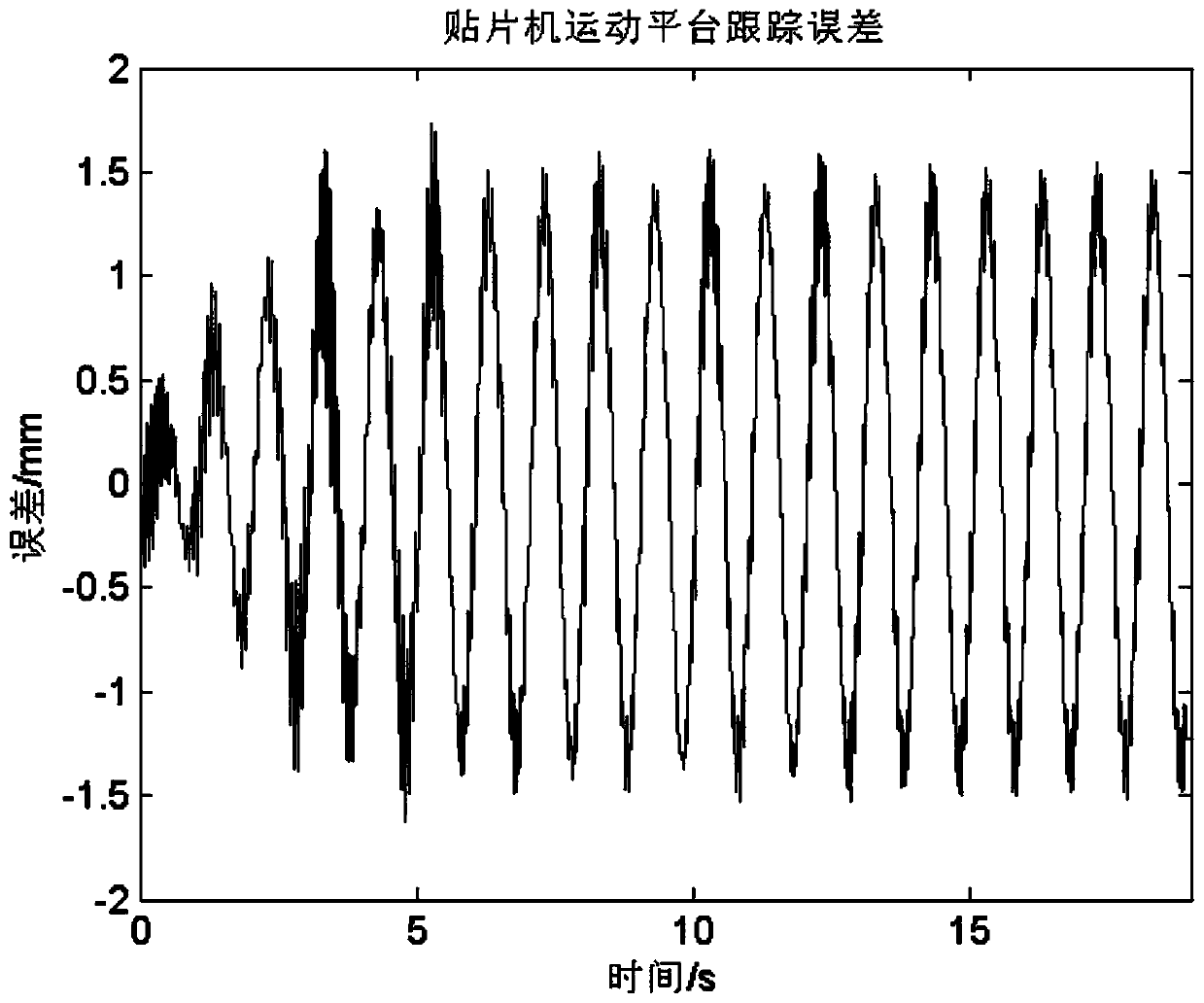

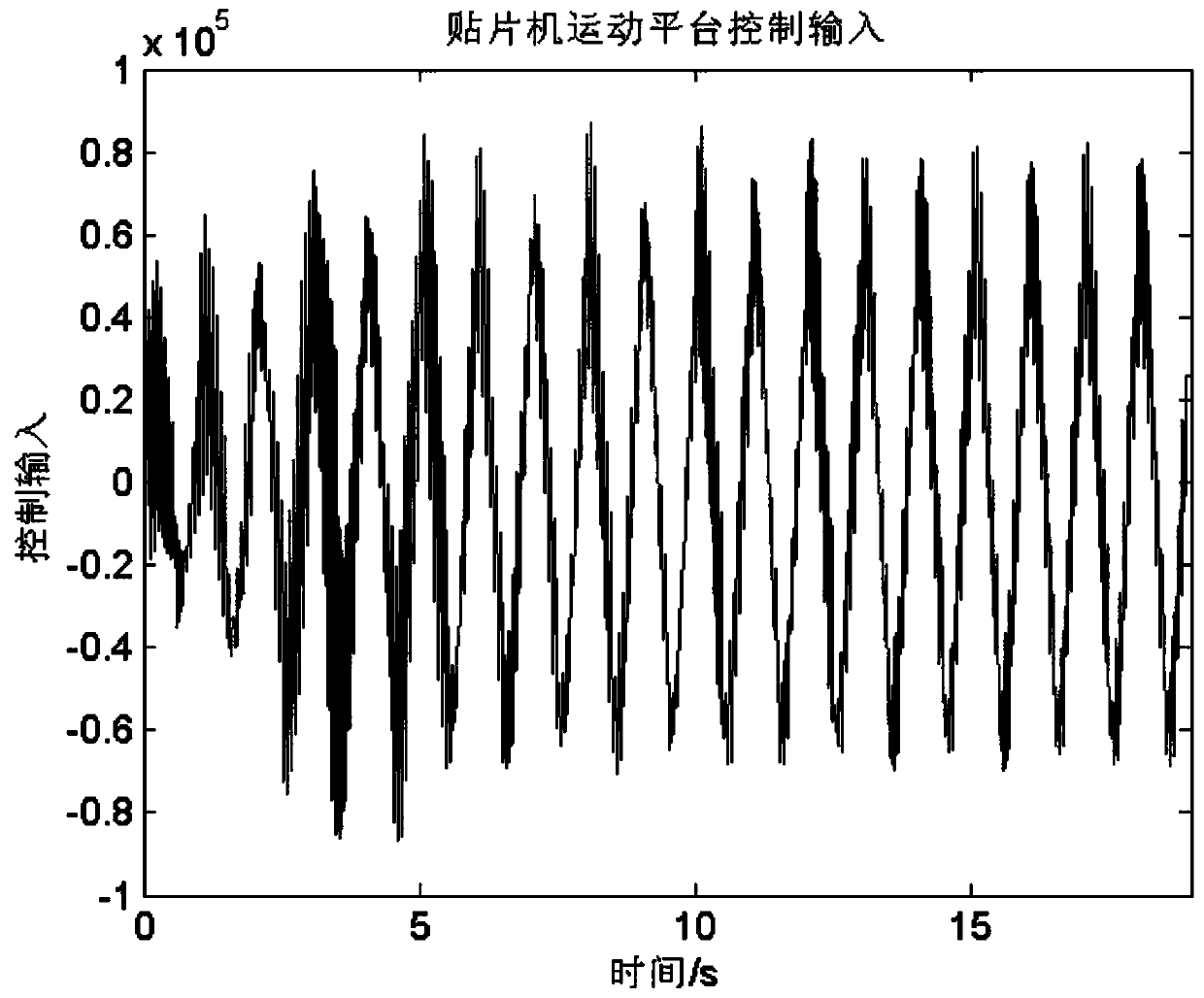

A scaling function and motion system technology, applied in the field of model identification and intelligent control of the motion system of the placement machine, can solve the problems of low tracking accuracy, achieve high accuracy, realize real-time tracking, and achieve good control effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0023] Specific embodiment one: the intelligent control method of the placement machine kinematic system based on binary spline scale function, comprises the following steps:

[0024] Step 1. Establish a dynamic model of the motion system of the placement machine moving along the horizontal axis or the vertical axis, wherein the horizontal axis is represented by x, and the vertical axis is represented by y; the specific process is:

[0025] Only consider the viscous friction force and Coulomb friction force on the motion platform of the mounter, and classify other model information not considered in the motion system of the mounter as the unmodeled dynamics of the system. According to Newton's second law, the sticking The dynamic equation when the chip motorized platform moves along the horizontal axis or the vertical axis, without loss of generality, we are considering the dynamic model of the motion system of the placement machine moving along the horizontal axis:

[0026] ...

specific Embodiment approach 2

[0034] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the step 2 constructs a binary spline scale function, and performs translation and telescopic transformation on it to establish a framework on the space of a binary square integrable function; The specific process is:

[0035] Construct unary spline scaling function as follows:

[0036]

[0037] in, z is the unary spline scaling function independent variable, is the set of all real numbers;

[0038] According to the constructed unary spline scaling function, construct the binary spline scaling function as follows:

[0039]

[0040] in, Indicates that with respect to the independent variable z 1 The unary spline scaling function of , Indicates that with respect to the independent variable z 2 The unary spline scaling function of z 1 is the binary spline scaling function independent variable, z 2 is the binary spline scaling function independent variable,

[0041] W...

specific Embodiment approach 3

[0046] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in Step 3, according to the framework established in Step 2, an appropriate scale is selected, and the unmodeled dynamic items in the model established in Step 1 Perform function approximation; the specific process is:

[0047] is a framework on the space of square-integrable functions and thus approximates the unmodeled dynamics with arbitrary precision And the approximation accuracy is only related to the selection of the scale parameter j. When j→-∞, the approximation accuracy will tend to 0, but it will take up a lot of storage space. Therefore, according to the specific conditions such as the operating environment and performance requirements of the motion system of the placement machine , select the appropriate scale parameter j, so that the impact of the approximation error on the control performance of the system is much smaller than the impact of the measurement noise (the noi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com