Improvement of Cold Stamping Technology of Stainless Steel Balls for Aeronautical Bearings

A cold stamping and stainless steel technology, which is applied in the field of cold stamping technology improvement of stainless steel balls for aviation bearings, can solve problems such as stamping cracks, and achieve the effects of thin ring belt, reduction of raw material loss and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0021] Specific implementation mode 1: In this implementation mode, the improvement of the cold stamping technology of stainless steel balls for aviation bearings is completed according to the following steps:

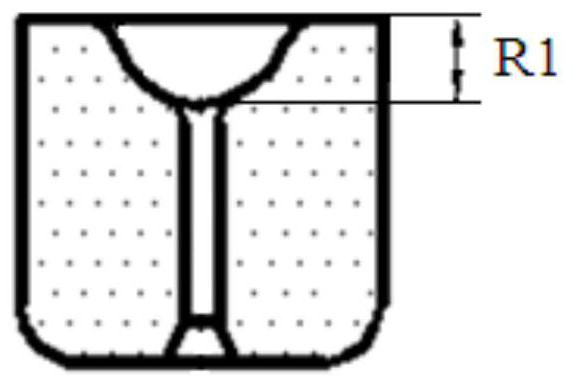

[0022] 1. Improvement of the mold: With the inner diameter of the mold unchanged from 4.64mm to 4.68mm, the ball height R2 of the mold is adjusted from the original 2.15mm to 2.19mm to 2.64mm to 2.68mm, and the improved tire is obtained. Tool;

[0023] 2. Cold stamping: The polished steel material is brought into the steel ball cold heading machine by the guide wheel, cut off, and then sent to the improved mold for cold stamping to obtain the cold stamped ball blank.

[0024] The beneficial effect of this implementation mode:

[0025] This embodiment improves the cold stamping technology of stainless steel balls for aerospace bearings. While keeping the inner diameter of the mold unchanged, the ball height of the mold is adjusted, and then the cold stamping is perform...

specific Embodiment approach 2

[0026] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step 1, the spherical height R2 of the mold is adjusted from the original 2.15 mm to 2.64 mm to obtain an improved mold.

[0027] Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0028] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 or 2 is: as described in step 2, the polished steel material is brought into the steel ball cold heading machine by the guide wheel, according to the size of the ball height R2 of the mold Cut off.

[0029] Other steps are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com