Metallocene polyethylene resin, preparation method and applications thereof

A metallocene polyethylene and metallocene catalyst technology, which is applied in the production of bulk chemicals, etc., can solve the problem that alkyl aluminoxane and active components are expensive, reduce the loading rate of active components, consume alkyl aluminoxane, etc. To achieve the effect of promoting development and application, improving hydrogen tuning response performance, and improving surface area and pore volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

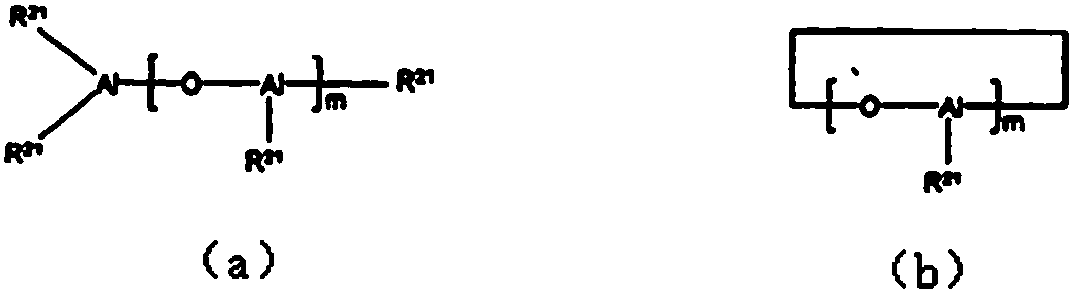

Method used

Image

Examples

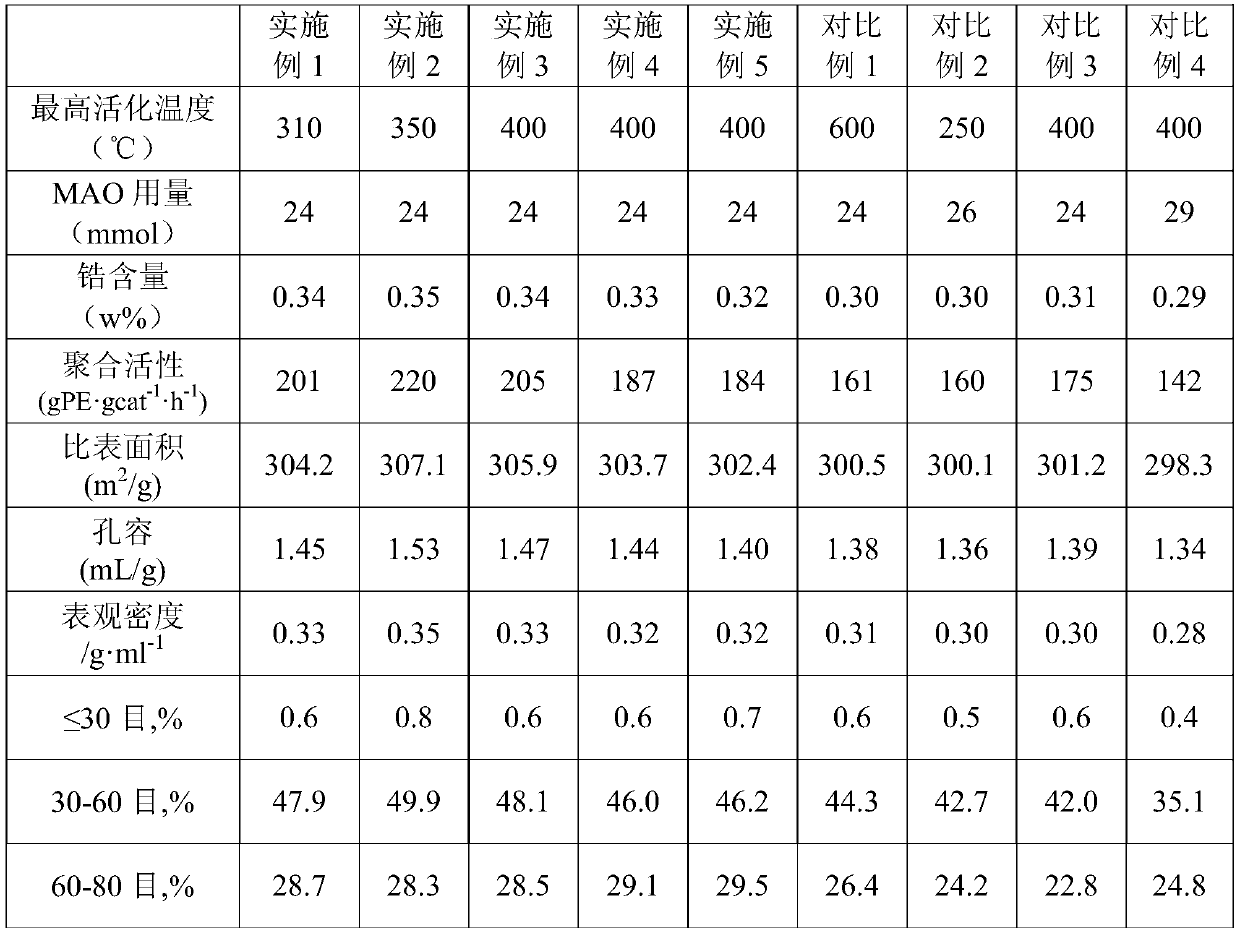

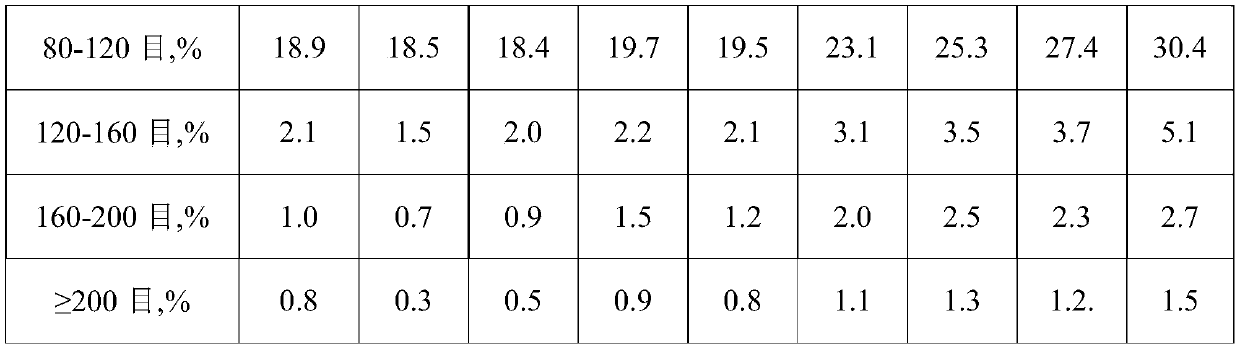

Embodiment 1

[0066] SiO 2 / MgCl 2 Preparation of composite carrier: First, replace a 250ml three-necked flask with a heating system and a stirring device and a reflux condensing system with nitrogen for no less than three times, then 1g anhydrous magnesium chloride, and add 5ml ethanol to raise the system temperature to 70 ℃, and keep the reaction at this temperature for 0.5 hours to obtain a magnesium alkoxide compound solution; add 4g of 955 silica gel to the magnesium alkoxide compound solution for 2 hours with constant temperature shaking; dry the silica gel / magnesium / alcohol mixture at 100 ℃ in a vacuum oven for 4 hours to get SiO 2 / MgCl 2 composite carrier, while heating the activation furnace to 310 °C. The dried SiO 2 / MgCl 2 The composite carrier was transferred to a quartz tube in an activation furnace, and the flow rate of high-purity nitrogen was adjusted to a replacement rate of 2.5, so that the carrier particles were in a fluidized state and kept at a constant temperatu...

Embodiment 2

[0070] SiO 2 / MgCl 2Preparation of composite carrier: First, replace a 250ml three-necked flask with a heating system and a stirring device and a reflux condensing system with nitrogen for no less than three times, then 1g anhydrous magnesium chloride, and add 5ml ethanol to raise the system temperature to 70 ℃, and keep the reaction at this temperature for 0.5 hours to obtain a magnesium alkoxide compound solution; add 4g of 955 silica gel to the magnesium alkoxide compound solution for 2 hours with constant temperature shaking; dry the silica gel / magnesium / alcohol mixture at 100 ℃ in a vacuum oven for 4 hours to get SiO 2 / MgCl 2 composite carrier, while heating the activation furnace to 350 °C. The dried SiO 2 / MgCl 2 The composite carrier was transferred to a quartz tube in an activation furnace, and the flow rate of high-purity nitrogen was adjusted to a replacement rate of 2.5, so that the carrier particles were in a fluidized state and kept at a constant temperatur...

Embodiment 3

[0074] SiO 2 / MgCl 2 Preparation of composite carrier: First, replace a 250ml three-necked flask with a heating system and a stirring device and a reflux condensing system with nitrogen for no less than three times, then 1g anhydrous magnesium chloride, and add 5ml ethanol to raise the system temperature to 70 ℃, and keep the reaction at this temperature for 0.5 hours to obtain a magnesium alkoxide compound solution; add 4g of 955 silica gel to the magnesium alkoxide compound solution for 2 hours with constant temperature shaking; dry the silica gel / magnesium / alcohol mixture at 100 ℃ in a vacuum oven for 4 hours to get SiO 2 / MgCl 2 composite carrier, while heating the activation furnace to 400 °C. The dried SiO 2 / MgCl 2 The composite carrier was transferred to a quartz tube in an activation furnace, and the flow rate of high-purity nitrogen was adjusted to a replacement rate of 2.5, so that the carrier particles were in a fluidized state and kept at a constant temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com