Hydrolysis-resistant, illumination-resistant and low-temperature-resistant halogen-free flame-retardant polycarbonate composite material and preparation method thereof

A technology of flame retardant polycarbonate and composite materials, applied in the field of halogen-free flame retardant polycarbonate composite materials and preparation, can solve the failure of flame retardant, the hydrolysis resistance is not evaluated, and the sulfonate flame retardant is not resistant to hydrolysis and other problems, to achieve the effect of not easy to hydrolyze, improve hydrolysis resistance and light aging resistance, and good impact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

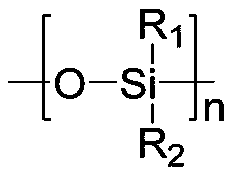

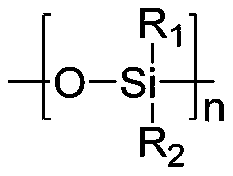

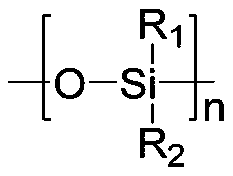

Image

Examples

Embodiment 1~7

[0048] The components and dosage of the halogen-free flame-retardant polycarbonate composite material with hydrolysis resistance, light resistance and low temperature resistance are shown in Table 1:

[0049] The toner is black mother UN2014.

[0050] According to the ratio in Table 1, each raw material component was mixed in a high-speed mixer for 6-8 minutes, then extruded, cooled, and granulated through a twin-screw extruder. The temperature in 11 zones of the twin-screw extruder was respectively set to 240°C, 250°C, 270°C, 270°C, 260°C, 260°C, 260°C, 260°C, 260°C, 260°C, 260°C; the obtained pellets were dried for 4 hours at a temperature of 120°C. It is injection-molded into standard splines under the condition of 260-280°C to obtain a halogen-free flame-retardant polycarbonate composite material that is resistant to hydrolysis, light, and low temperature.

Embodiment 11

[0066] The polysiloxane flame retardant in Example 11 is a linear polysiloxane flame retardant, the brand is RM4-7051, purchased from Dow Corning.

[0067] table 3

[0068]

[0069]

[0070] The performance test data of Examples 8-11 and Comparative Examples 5 and 6 are shown in Table 4, and the specific method is the same as that of Example 1.

[0071] Table 4

[0072]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com