Aluminum profile oxidation processing line

An aluminum profile oxidation and processing line technology, applied in the direction of anodic oxidation, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problems of unsmooth intermediate links of materials, low production efficiency of aluminum profiles, no automatic lifting platform, etc., to achieve drying Excellent drying effect, improved quality, and faster circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

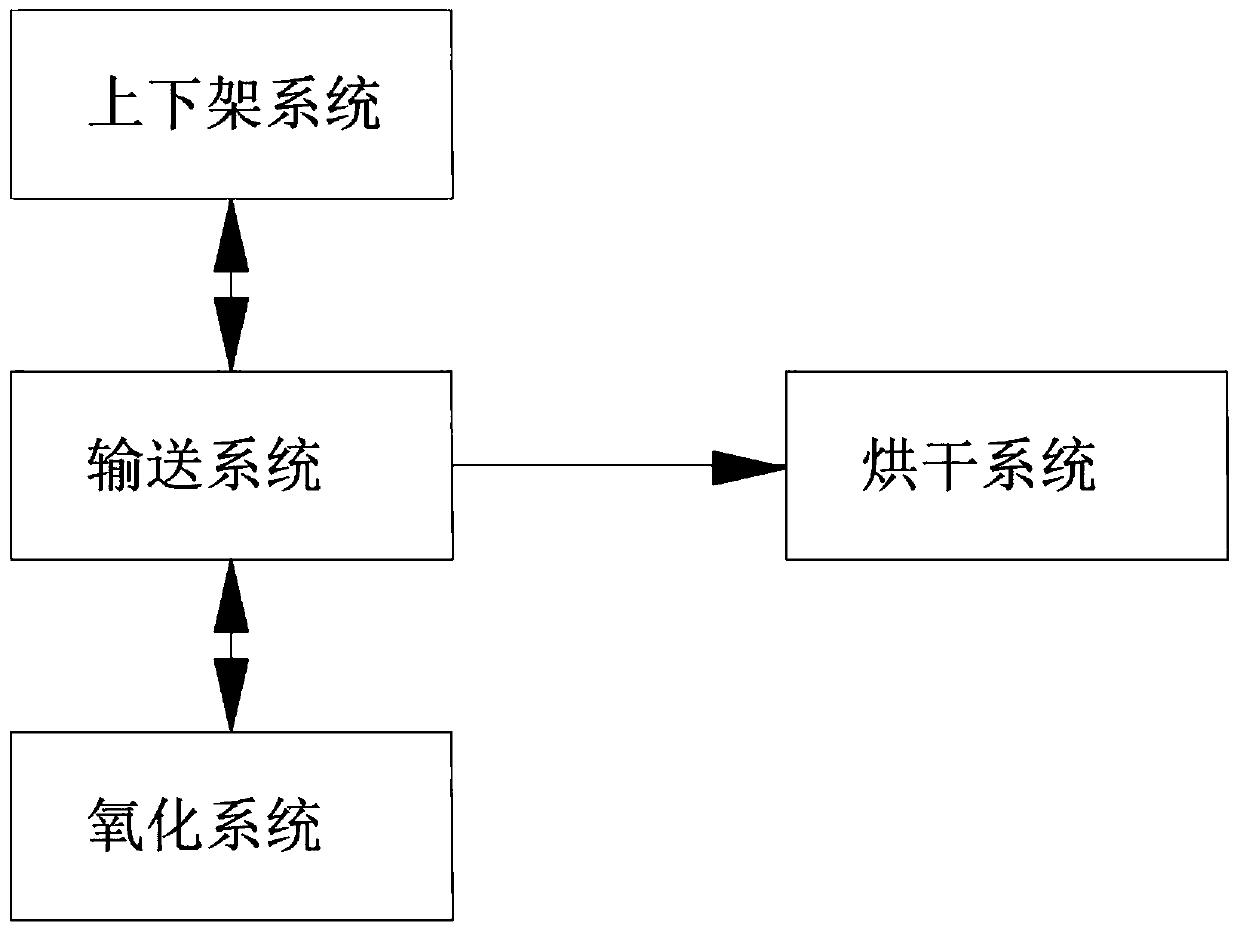

[0036] refer to figure 1 As shown, the aluminum profile oxidation treatment line, the aluminum profile oxidation treatment line is a closed-loop management oxidation production line. The closed-loop management oxidation production line includes a loading and unloading system, a conveying system, an oxidation system and a drying system. The loading and unloading system and the conveying system are bidirectionally connected , the oxidation system is connected to the conveying system in two directions, the conveying system is connected to the drying system in one direction, the loading and unloading system is connected to the oxidation system through the conveying system, and connected to the drying system through the conveying system;

[0037] The upper and lower rack system is used to hoist the aluminum profile to the bent rack, and then transport the finished aluminum profile to the feeding truck by the crane, and then transport it to the surface of the oxidation tank, complete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com