Method for verifying extension length of main crack of fracturing in coal bed methane wells

A technology for coalbed methane wells and verification methods, applied in earthwork drilling, wellbore/well components, production fluids, etc., to achieve the effect of data processing and model establishment optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

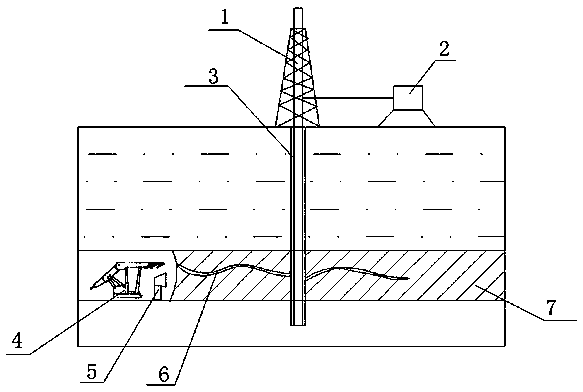

[0011] Such as figure 1 As shown, a method for verifying the extension length of main fractures in the fracturing of coalbed methane wells. Firstly, in combination with the project progress of the coal mine, the surface coalbed methane well 3 is laid out in advance. During the fracturing construction, the fracturing sand and fracturing hydraulic pressure will be injected into the coal seam after the fluorescent agent is transformed. During the fracturing process, the microseismic fracture monitoring technology was used on the ground to determine the approximate orientation of the main fracture 6, and then compared with the underground construction progress chart, the occurrence area and orientation of the main fractures were judged in advance, and the mining face that might be exposed soon was made. In the key monitoring area, an ultraviolet searchlight 5 for coal mine is arranged in front of the mining work, and the irradiation range is required to cover the working face. When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com