A closed-loop control method and system for a rear oxygen sensor of a natural gas engine

A rear oxygen sensor and closed-loop control technology, which is applied in engine control, electrical control, engine components, etc., can solve the problems affecting the stability of the rear oxygen closed loop, the fluctuation state of air-fuel ratio, and the system is difficult to stabilize, so as to achieve the benefit of emission consistency, Effects of improving stability and improving robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

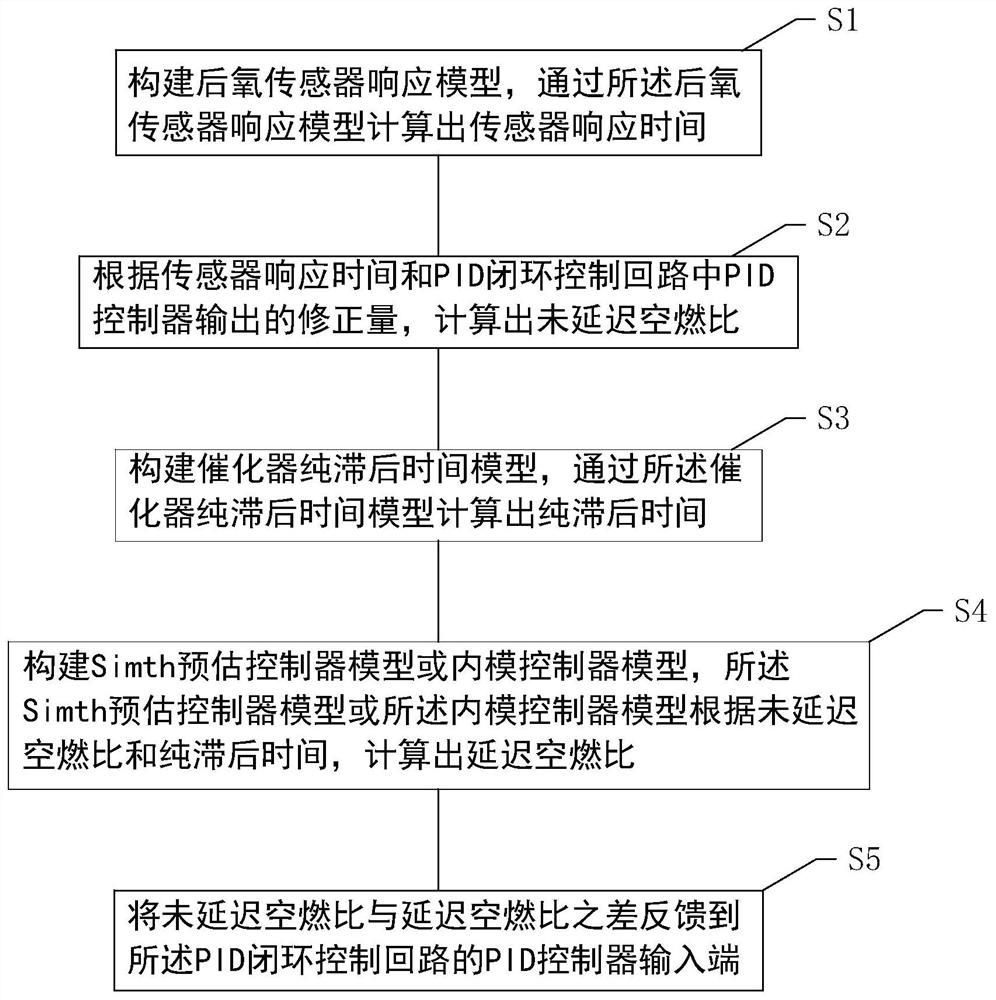

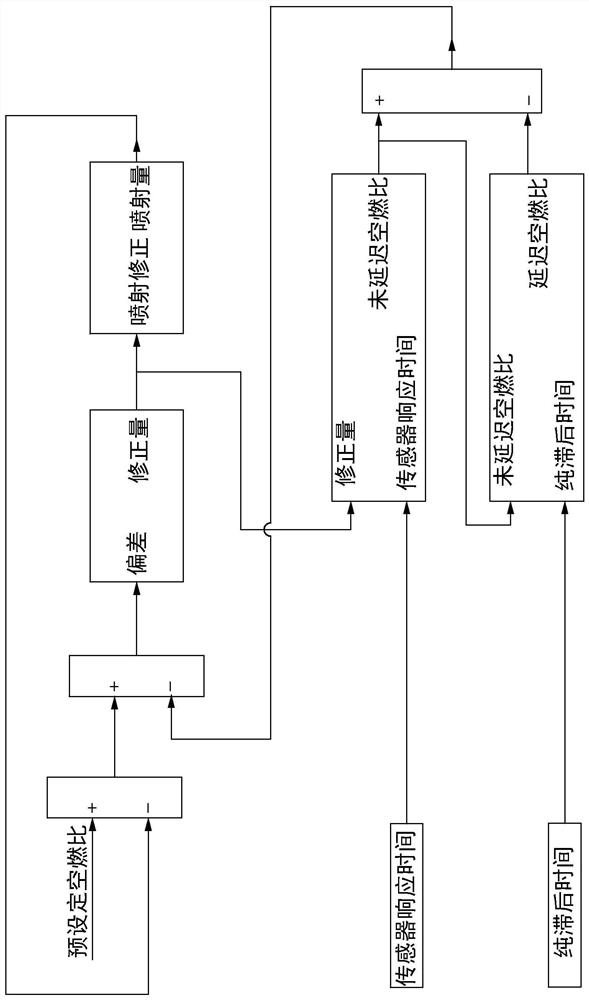

[0031] Such as figure 1 and figure 2 As shown, a closed-loop control method of a rear oxygen sensor of a natural gas engine is based on a rear oxygen sensor PID closed-loop control loop, comprising the following steps:

[0032] S1. Construct the rear oxygen sensor response model, and calculate the sensor response time through the rear oxygen sensor response model;

[0033] S2. Calculate the undelayed air-fuel ratio according to the sensor response time and the correction amount output by the PID controller in the PID closed-loop control loop;

[0034] S3. Construct the pure lag time model of the catalytic converter, and calculate the pure lag time through the pure lag time model of the catalytic converter;

[0035] S4, build Simth predictive controller model or internal model controller model, Simth predictive controller model or internal model controller model calculates delayed air-fuel ratio according to undelayed air-fuel ratio and pure lag time;

[0036] S5. Feedback ...

Embodiment 2

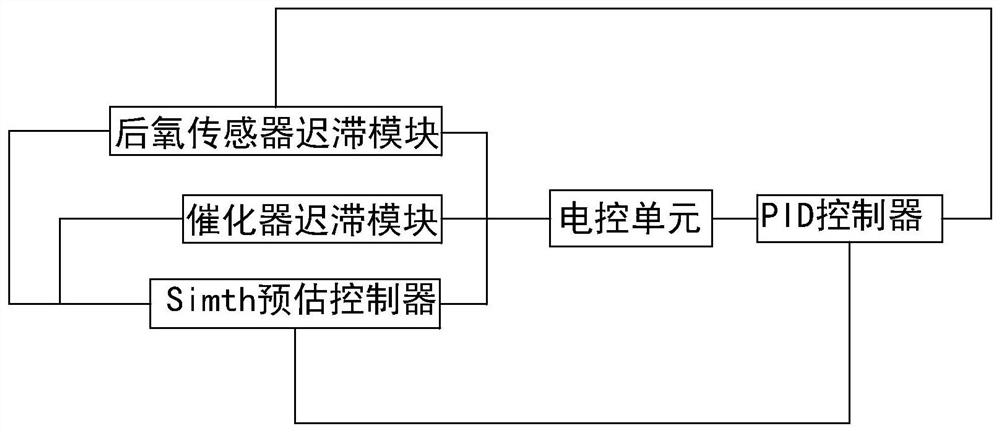

[0066] Such as image 3 and Figure 4 As shown, a closed-loop control system of a rear oxygen sensor of a natural gas engine includes a rear oxygen sensor PID closed-loop control loop, and also includes a rear oxygen sensor hysteresis module, a catalytic converter hysteresis module and a Simth predictive controller or an internal model controller.

[0067] The rear oxygen sensor hysteresis module is used to construct the rear oxygen sensor response model, calculate the sensor response time through the rear oxygen sensor response model, and calculate the non-delay air-fuel ratio;

[0068] The catalytic converter hysteresis module is used to construct the pure lag time of the catalytic converter, and the pure lag time is calculated through the pure lag time of the catalytic converter;

[0069] Wherein the input end of the Simth predictive controller or the internal model controller is electrically connected with the output end of the rear oxygen sensor hysteresis module and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com