Fat mimic with Harbin red sausage flavor and preparation method thereof

The technology of fat simulant and Hahong sausage is applied in the research field of fat simulant of Hahong sausage. low content effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

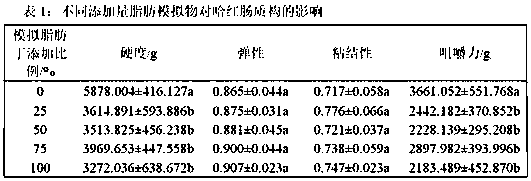

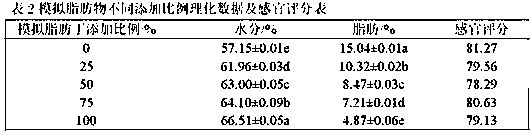

Examples

Embodiment 1

[0025] A Kazakh sausage-flavored fat simulant was made from the following weights:

[0026] Water 100Kg, konjac gum 4Kg, gellan gum 3 Kg, maltodextrin 3.5 Kg, soybean protein isolate 1 Kg, tapioca modified starch 3 Kg, pork bone essence 0.15 Kg and baking soda (NaHCO 3 ) 0.1kg.

[0027] The preparation operation steps of a kind of fat simulant are as follows:

[0028] (1) Prepare the mixture

[0029] Mix konjac gum, gellan gum, maltodextrin, soybean protein isolate, tapioca modified starch, pork bone essence, water and baking soda according to the formula until fully dissolved to obtain a mixture;

[0030] (2) Preparation of fat simulants

[0031] Precook the mixture for 60 minutes in a water bath at 90°C to achieve gelatinization; cool in a refrigerator at 0-4°C for 24 hours; continue to boil for another 30 minutes in a water bath at 90°C to ensure gelatinization Insoluble; cooled with cold water for 30 minutes to prepare the fat simulant; the physical characteristic of t...

Embodiment 2

[0040] A Kazakh sausage-flavored fat simulant was made from the following weights:

[0041] Water 100 Kg, konjac gum 5 Kg, gellan gum 3.5 Kg, maltodextrin 2 Kg, tapioca modified starch 4 Kg, pork bone essence 0.2 Kg and baking soda (NaHCO 3 ) 0.15kg.

[0042] The preparation operation steps of a kind of fat simulant are as follows:

[0043] Mix konjac gum, gellan gum, maltodextrin, soybean protein isolate, tapioca modified starch, pork bone essence, water and baking soda according to the formula until fully dissolved to obtain a mixture;

[0044] (2) Preparation of fat simulants

[0045] Precook the mixture for 60 minutes in a water bath at 90°C to achieve gelatinization; cool in a refrigerator at 0-4°C for 24 hours; continue to boil for another 30 minutes in a water bath at 90°C to ensure gelatinization Insoluble; cooled with cold water for 30 min to obtain a fat simulant; the physical characteristics of the fat simulant are milky white elastic jelly that can be diced with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com