Dust collector main machine

A technology for vacuum cleaners and hosts, which is applied in the direction of vacuum cleaners, suction filters, handles, etc. It can solve problems such as unsmooth airflow, large suction loss, and non-disassembly, and achieve the effects of reasonable structural layout, small suction loss, and high suction power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

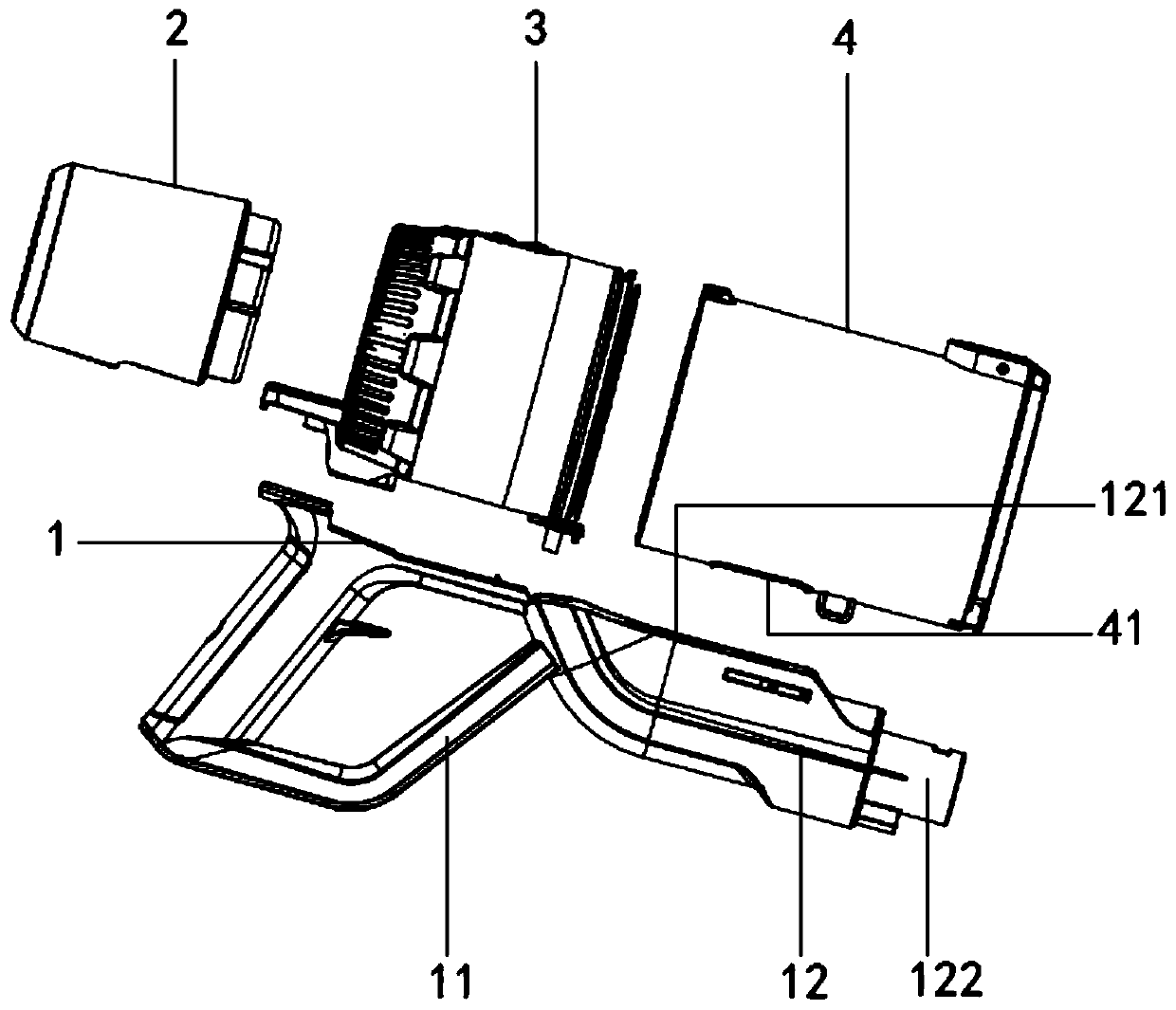

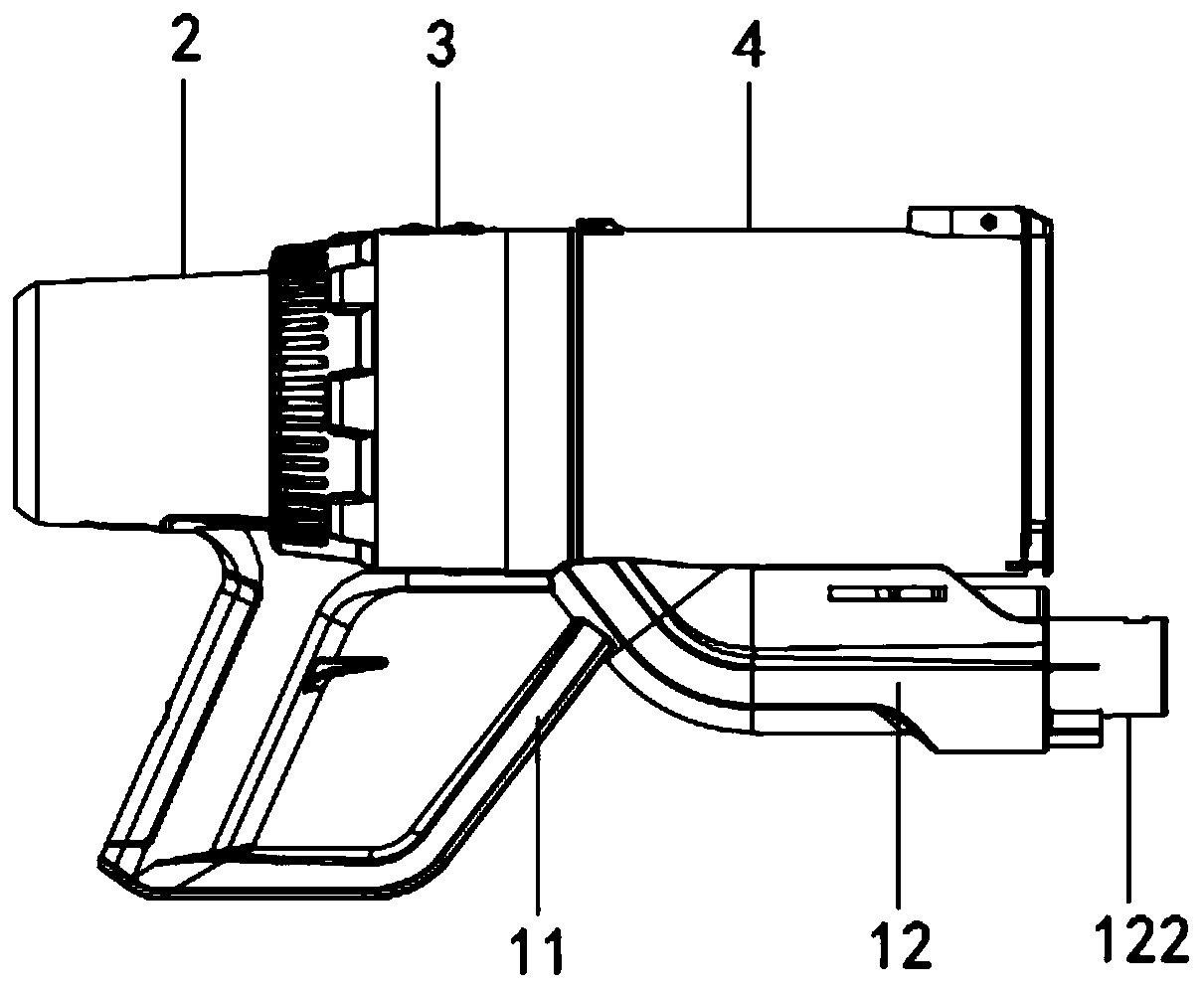

[0022] see Figure 1 to Figure 2 , this embodiment provides a vacuum cleaner main unit, first of all, a mounting base 1, a battery 2, a motor 3 and a dust cup 4 are provided, the battery 2, the motor 3 and the dust cup 4 are all installed on the mounting base 1, and the mounting base 1 is provided with There is a handle 11 and an air inlet pipe 12, the air inlet pipe 12 is fixedly connected to the handle 11, the motor 3 is detachably installed on the mounting base 1, and the position of the motor 3 corresponds to the position of the handle 11, and the battery 2 is detachably installed on the The first end of the motor 3 and the dust cup 4 are detachably mounted on the second end of the motor 3 , and the position of the dust cup 4 corresponds to the position of the air inlet pipe 12 .

[0023] continue to see Figure 1 to Figure 2 , the battery 2, the motor 3 and the dust cup 4 are located on the same axis, the battery 2, the motor 3 and the dust cup 4 are all located above th...

Embodiment 2

[0030] see Figure 1 to Figure 2 , the figure shows a vacuum cleaner main unit provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: the air inlet pipe 12 is provided with a second A tuyere 121, the dust cup 4 is provided with a second tuyere 41 matching the first tuyere 121, the first tuyere 121 is located on the upper surface of the air inlet pipe 12, the second tuyere 41 is located on the lower surface of the dust cup 4, the first tuyere 121 1. An air duct is formed between the second tuyere 41 and the pipe mouth 122 of the air inlet pipe 12, and the wind force enters the dust cup 4 after passing through the air duct. This air duct is a trumpet structure, and the pipe mouth 122 is the entrance of the air duct. It is the outlet of the air duct, and the size of the nozzle 122 is smaller than that of the second air outlet 41 , so the wind speed at the ...

Embodiment 3

[0032] see Figure 1 to Figure 2 , the figure shows a vacuum cleaner main unit provided by the third embodiment of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: the air inlet pipe 12 is provided with a second A tuyere 121, the second tuyere 41 matching the first tuyere 121 is opened on the dust cup 4, and an arc-shaped limiting plate is respectively arranged on opposite sides of the first tuyere 121, and the two arc-shaped limiting plates are respectively wrapped in dust On the opposite side walls of the cup 4, on the one hand, the positional stability of the dust cup 4 is improved, and on the other hand, the leakage of wind force can be avoided.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com