Full-automatic drying, purifying and pressure reducing device applied to SF6 gas transmission system

A technology of decompression device and gas transmission system, which is applied in the direction of chemical instruments and methods, separation methods, and separation of dispersed particles, which can solve the problems of large regeneration gas and loss, achieve environmental protection, ensure inflation speed, and reduce greenhouse gas emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

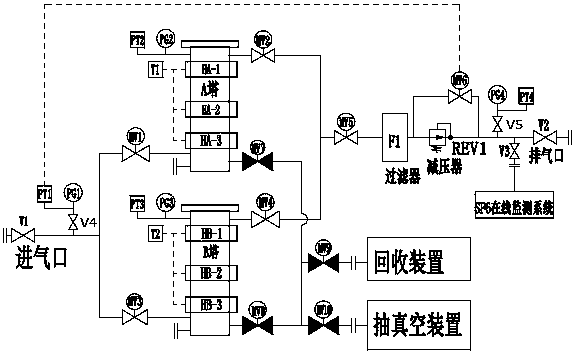

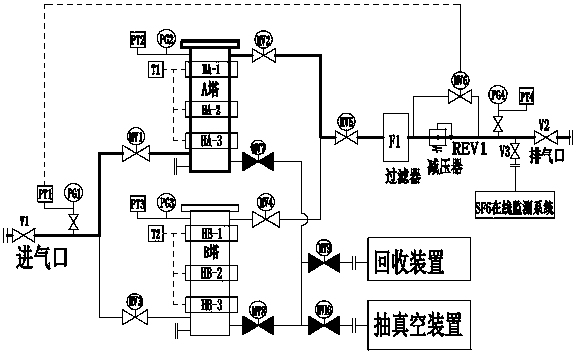

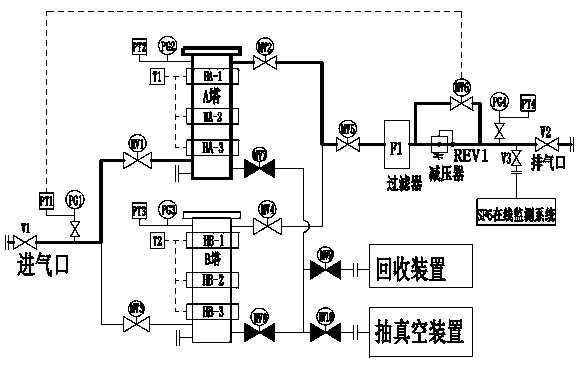

[0024] A fully automatic drying, purification and decompression device applied to SF6 gas transmission system, including a controller, a purification and decompression system, an online monitoring system for monitoring the purity of the purification and decompression system, and a gas for recovering the gas in the purification and decompression system Automatic regeneration system, purification decompression system includes decompression system and dry purification system, gas automatic regeneration system includes recovery system, heating system and vacuum purification system, online monitoring system, decompression system, heating system, recovery system, heating system and vacuum The purification system is installed on the dry purification system, and the controller is electrically connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com