Stirring device for ferrite soft magnetic core production

A stirring device and soft magnetic core technology, which is applied to mixers with rotating stirring devices, transportation, packaging, dissolution, etc., can solve the problems of low efficiency and manpower consumption, and achieve labor-saving lifting, efficiency improvement, and meet the needs of use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

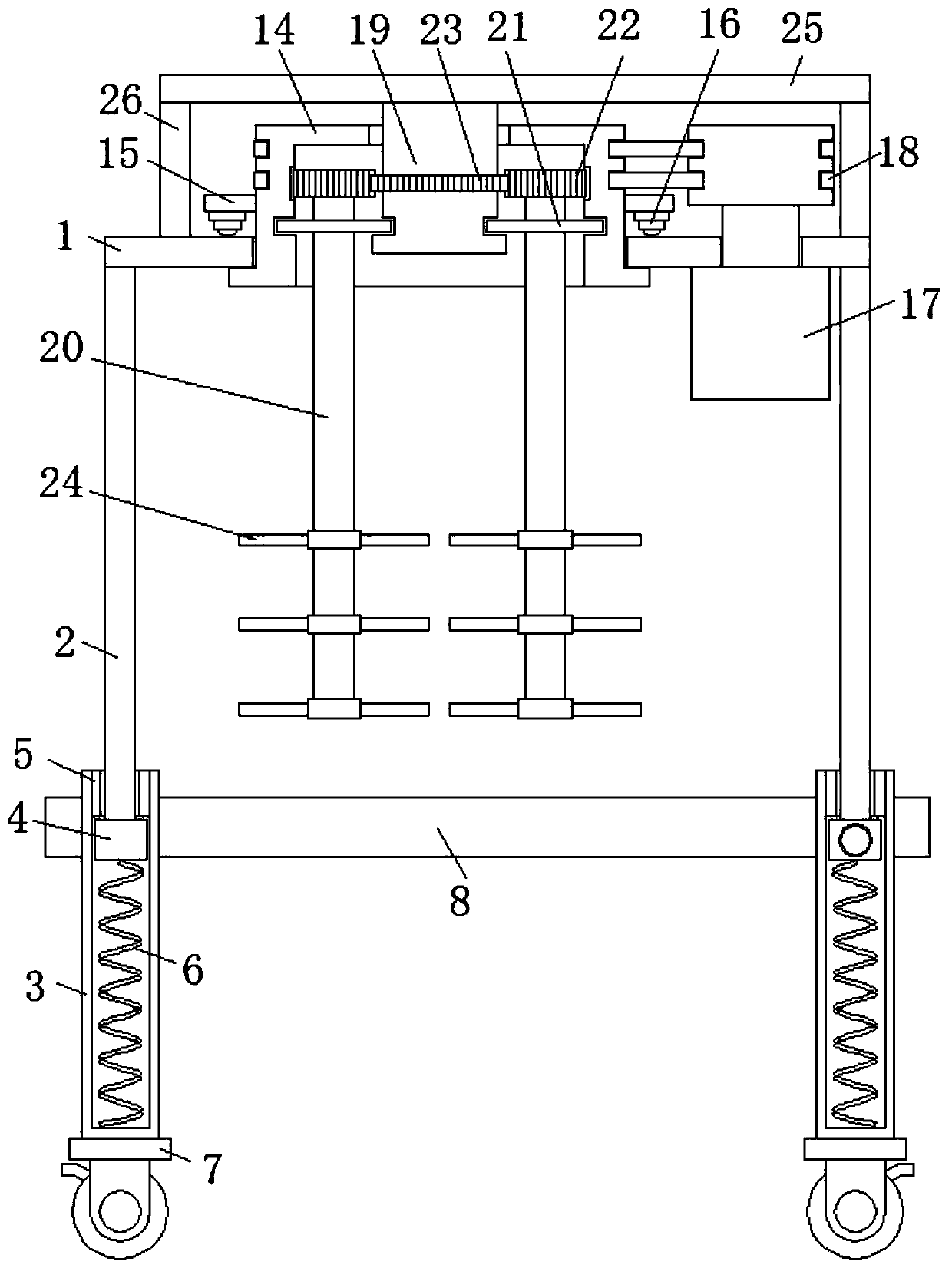

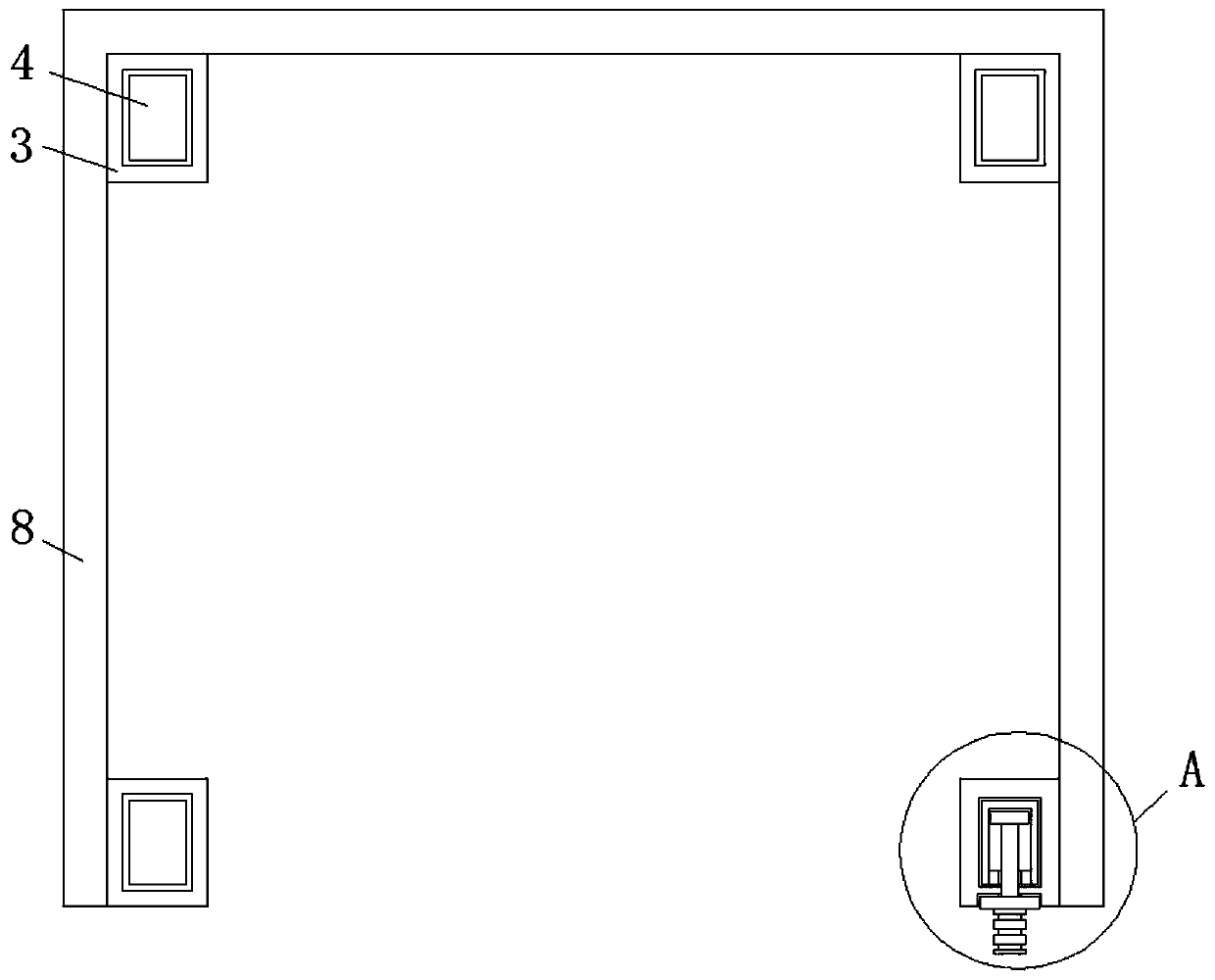

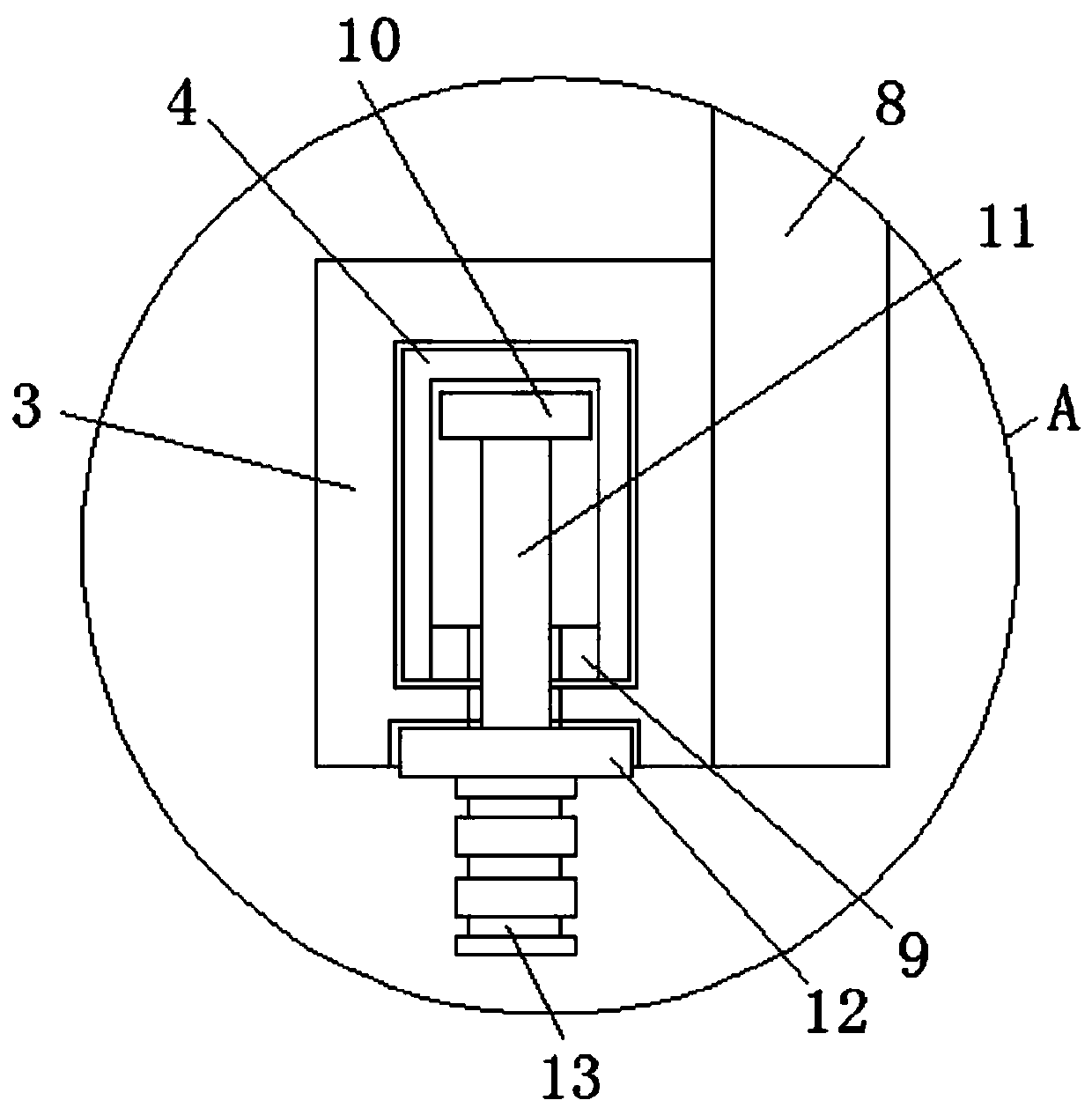

[0024] refer to Figure 1-6 , a stirring device for ferrite soft magnetic core production, comprising a mounting table 1, the four corners of the bottom of the mounting table 1 are fixedly connected with legs 2, the sliding sleeve at the bottom of the leg 2 is provided with a sliding sleeve 3, and the top of the sliding sleeve 3 A top chute is provided, the inner wall of the top opening of the top chute is fixedly connected with the limit ring 15, and the sliding column 4 is slidably connected in the top chute, and the bottom side of the sliding column 4 is arranged between the bottom side inner wall of the top chute. Auxiliary support spring 6 is arranged, and one side of the vertical side of the top chute of the top chute is provided with a slide hole, and one side of the sliding column 4 in the top chute is provided with a side groove, and the opening inner wall of the side groove is fixed Connect the limiting ring 2 9, the slide block 10 is connected horizontally in the si...

Embodiment 2

[0028] Such as Figure 1-6 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the planetary gear 22 is located on the top side of the limiting swivel 21 .

[0029] In this embodiment, both sides of the planetary gear 22 mesh with the sun gear ring 23 and the tooth groove respectively to form a rotation, and the ring groove 1 and the ring groove 2 support the limit swivel 21 in the vertical direction.

Embodiment 3

[0031] Such as Figure 1-6 As shown, this embodiment is basically the same as Embodiment 1. Preferably, locking universal wheels 7 are installed at the bottom ends of the sliding sleeves 3 .

[0032] In this embodiment, the movement of the equipment is facilitated, and the mobility of the equipment is increased.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com